Specifications: seawater service option, Specifications, Dimensions – Cla-Val 50B-4KG1/2050B-4KG1 Technical Manual User Manual

Page 17: Purchase specifications, Valve capacity, Cla-val

PO Box 1325 Newport Beach CA 92659-0325

Phone: 949-722-4800

Fax: 949-548-5441

Web Site: cla-val.com

E-mail: [email protected]

CLA-VAL

CLA-VAL CANADA

CLA-VAL EUROPE

4687 Christie Drive

Beamsville, Ontario

Canada L0R 1B4

Phone: 905-563-4963

Fax: 905-563-4040

E-Mail: [email protected]

Chemin des M

ésanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

E-Mail: [email protected]

Copyright CLA-VAL 2014 Printed in USA Specifications subject to change without notice.

CLA-VAL UK

Dainton House, Goods Station Road

GB - Tunbridge Wells

Kent TN1 2 DH England

Phone: 44-1892-514-400

Fax: 44-1892-543-423

E-Mail: [email protected]

©

Represented By:

Specifications: Seawater Service Option

Sizes

Globe: 2" - 8" flanged

Angle: 2" - 8" flanged

Consult factory for flange ratings.

See page 1 for seawater service materials options.

E-50B-4KG1/2050B-4KGL1 (R-04/2014)

Model 2050B-4KG1 Angle

Model 50B-4KG1 Globe

We recommend providing adequate space around valve for maintenance work.

Specifications

Globe: 2" - 10” flanged

Angle: 2" - 10" flanged

150 and 300 ANSI B16.42

class - 175 psi Max.

class - 300 psi Max

Water, to 180°F Max.

Main Valve Body & Cover

Ductile Iron ASTM A536 Grade 65-45-12

Standard Main Valve Trim:

Bronze Seat, Teflon Coated

Stainless Steel Stem, Dura-Kleen Stem

Standard Pilot Control System:

Cast Bronze with

Stainless Steel trim

Available in the following relief

pressure ranges:

20-200 psi (150 Class)

100-300 psi (300 Class)

Protective epoxy resin coating

of wetted surfaces of main

valve cast iron components

(UL listed HNFX EX2855)

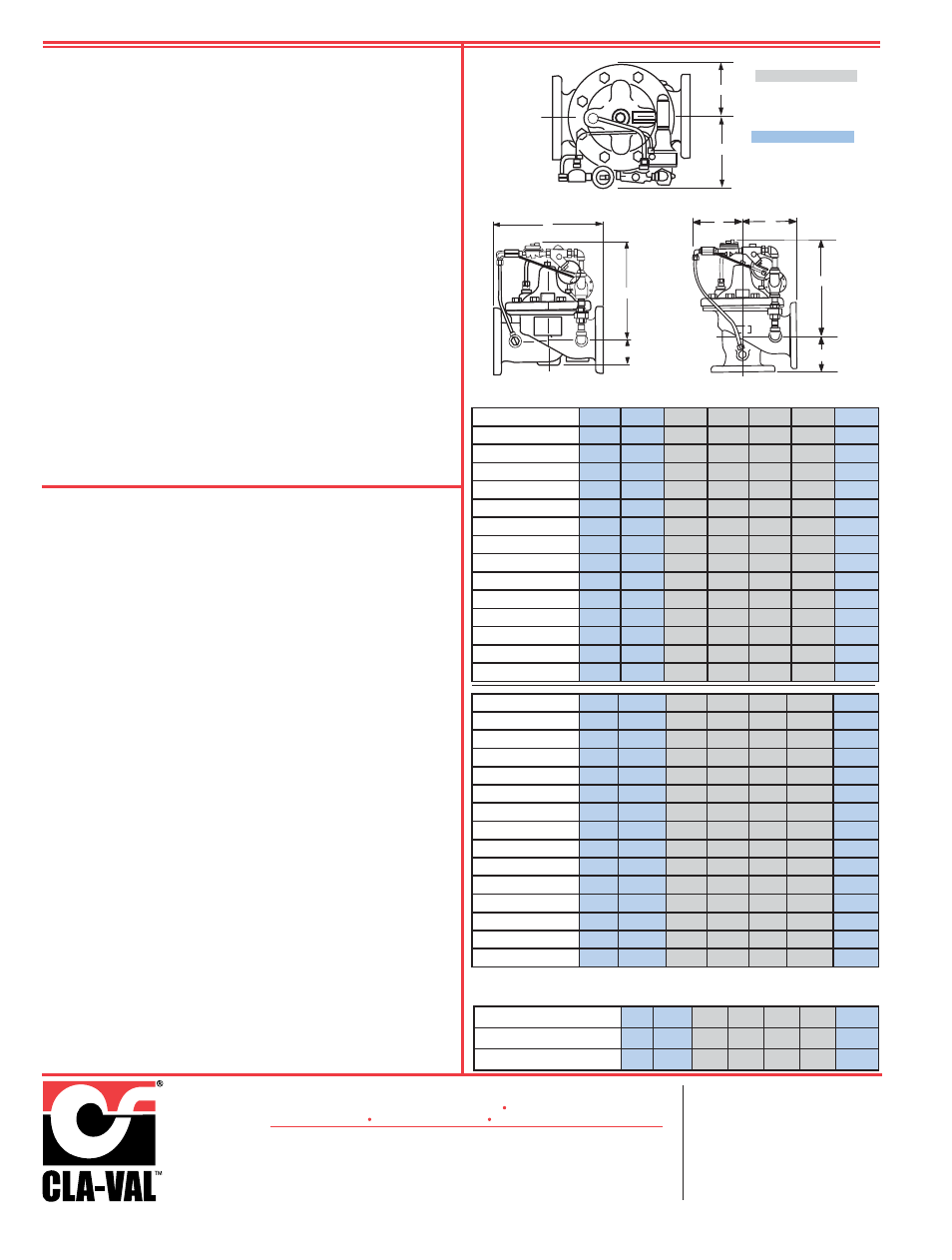

Dimensions

B

G

C

F

H

E

C

D

A

The Fire Pump Pressure Relief Valve shall modulate to relieve excess

pressure in a fire protection system. It shall maintain constant pressure

in the system regardless of demand changes. It shall be pilot controlled

and back pressure shall not affect its set point. It shall be actuated by

line pressure through a pilot control system and open fast in order to

maintain steady system pressure as system demand decreases. It shall

close gradually to control surges and shall re-seat drip-tight within 5% of

its pressure setting. The main valve shall be of the hydraulically-operat-

ed, pilot-controlled, diaphragm-type, globe or angle valve. It shall have

a single, removable, teflon-coated seat, a grooved stem guided at both

ends, and a resilient disc with a rectangular cross section, being con-

tained on 3 1/2 sides. No external packing glands shall be permitted and

the diaphragm shall not be used as a seating surface. The pilot control

shall be a direct-acting, adjustable, spring-loaded, diaphragm-type valve

designed for modulating service to permit flow when controlling pressure

exceeds spring setting. This valve shall be UL Listed and Factory Mutual

approved. It shall be the Model 50B-4KG1 (globe) or Model 2050B-

4KG1 (angle) Pressure Relief Valve as manufactured by Cla-Val Newport

Beach, California.

*Special Note:

The Model 50B-4KG1 Pressure Relief Valve is available with 300# ANSI

inlet flange and 150# ANSI outlet flange. This valve is used on higher

pressure systems where 300# flange connections are required, and

allows for adapting of a discharge cone (generally supplied with 150#

flange) to accommodate "atmospheric break" at relief valve discharge.

This relief valve, with 300# / 150# flanges is available on special order,

and is UNDERWRITERS LABORATORIES LISTED AND FACTORY

MUTUAL APPROVED.

Purchase Specifications

Sizes

End Details

Pressure Ratings

Standard Materials

Adjustment Range

Optional

Valve Capacity

Valve Sizes in Inches:

2"

2 1/2"

3"

4"

6"

8"

10"

NFPA 20 Maximum

Recommended GPM

208

300

500 1000 2500 5000 11000

= U.L., F.M. and

ULC sizes

Valve Size

(inches)

2”

2-1/2”

3”

4”

6”

8”

10”

Threaded Ends

9.38

11.00

12.50

- - -

- - -

- - -

- - -

A 150 Flanged

9.38

11.00

12.00

15.00

20.00

25.38

29.75

300 Flanged

10.00

11.62

13.25

15.62

21.00

26.38

31.12

300 X 150

12.88

15.31

20.56

25.88

30.44

B

3.31

4.00

4.56

5.75

7.88

10.00

11.81

C

12.00

12.25

12.50

13.00

14.31

16.31

18.00

D

1.50

1.69

2.66

3.19

4.31

5.31

9.25

Threaded Ends

4.75

5.50

6.25

- - -

- - -

- - -

- - -

E

150 Flanged

4.75

5.50

6.00

7.50

10.00

12.75

14.88

300 Flanged

5.00

5.88

6.38

7.88

10.50

13.25

15.56

Threaded Ends

3.25

4.00

4.50

- - -

- - -

- - -

- - -

F

150 Flanged

3.25

4.00

4.00

5.00

6.00

8.00

8.62

300 Flanged

3.50

4.31

4.38

5.31

6.50

8.50

9.31

G & H

6.00

6.69

7.75

7.88

8.50

9.75

13.25

Valve Size

(mm)

50

65

80

100

150

200

250

Threaded Ends

238

279

318

- - -

- - -

- - -

- - -

A 150 Flanged

234

279

305

381

508

645

756

300 Flanged

254

295

337

397

533

670

790

300 X 150

- - -

- - -

327

389

522

657

773

B

84

102

116

146

200

254

300

C

305

311

1318

330

363

414

457

D

38

43

65

81

109

135

235

Threaded Ends

121

140

159

- - -

- - -

- - -

- - -

E

150 Flanged

121

140

152

191

254

324

378

300 Flanged

127

149

162

200

267

337

395

Threaded Ends

83

102

114

- - -

- - -

- - -

- - -

F

150 Flanged

83

102

102

127

152

203

219

300 Flanged

89

109

111

135

165

216

236

G & H

152

170

197

200

216

248

337

= ULC sizes only