Cla-Val CRD40 User Manual

Crd40, Pressure reducing control

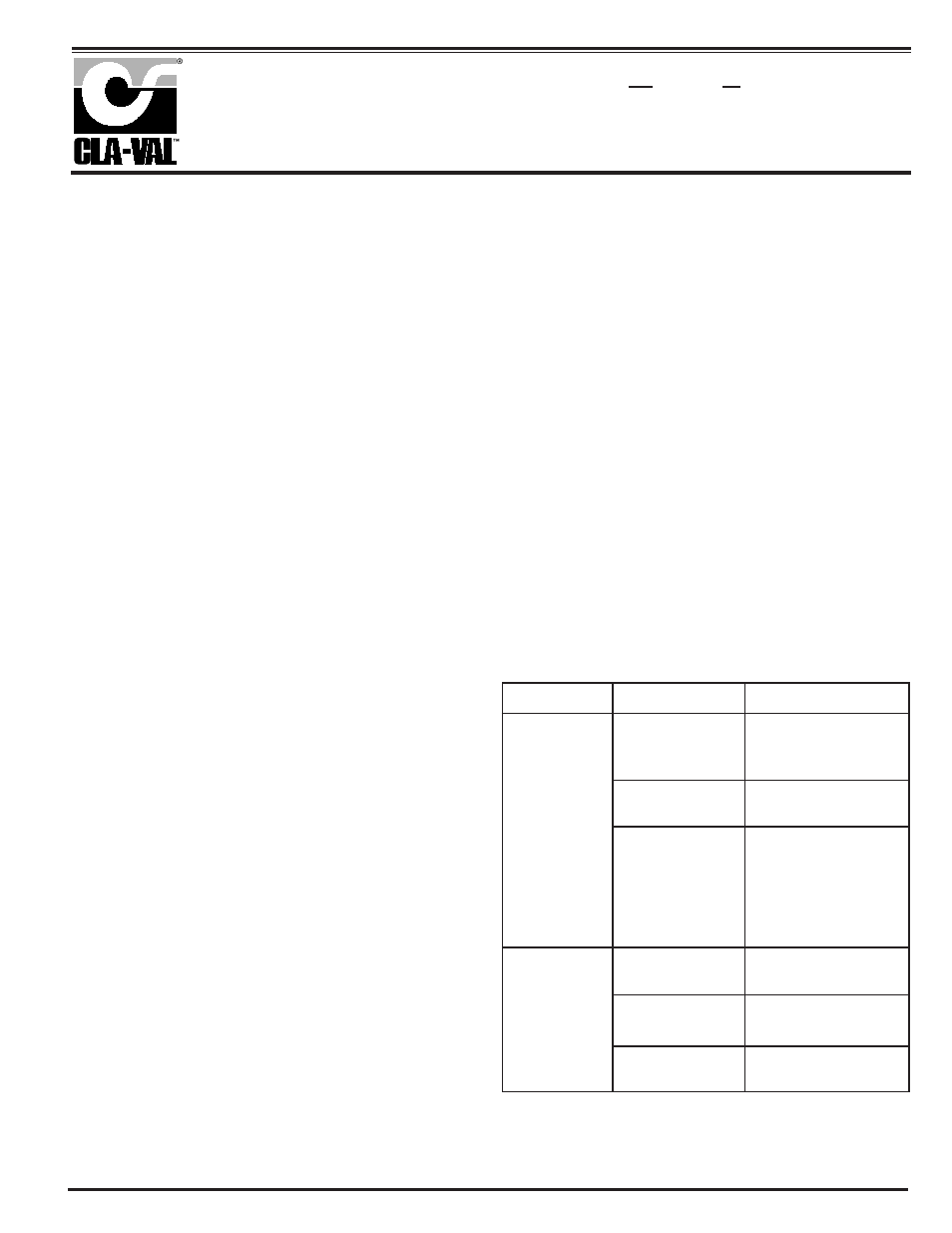

Symptom

Fails to close

when outlet

pressure rises

Fails to open

when outlet

pressure lowers

Probable Cause

Foreign matter on

seating face of seal

O-ring

Cartridge assembly

damaged

Cut or worn stem

O-ring or worn

O-ring groove

Spring compressed

solid

Cartridge assembly

damaged

No spring

compression

Damaged spring

Remedy

Disassemble and

remove

Disassemble and

replace

Replace cartridge

assembly

Loosen

adjustment bolt

Disassemble

and replace

Tighten adjustment

bolt

Disassemble and

replace

Pressure Reducing Control

CRD40

MODEL

Description

The CRD40 Pressure Reducing Control automatically reduces a

higher inlet pressure to a lower outlet pressure. It is a direct act-

ing, spring loaded, diaphragm type control that operates hydrauli-

cally. It is used as a pilot control with Cla-Val automatic control

valves to hold a constant downstream pressure. Cla-Val Model

CRD40 maximum inlet pressure rating: 400 psi

Installation and Adjustment

Before installing the CRD40 Pressure Reducing Control, flush out

line to remove loose dirt and scale which might damage seal ring

and seat. Install control in-line with arrow on valve body pointing

in direction of flow. The CRD40 may be installed in any position.

The standard adjustment range is 15 to 150 psi with a factory set-

ting of 50 psi. To readjust outlet pressure, loosen lock nut and

turn adjustment bolt clockwise (into bell housing) to raise outlet

pressure. To lower outlet pressure setting turn adjustment bolt

counterclockwise (out of bell housing).

Caution: A pressure gauge must be used downstream to verify

correct pressure setting. Do not bottom out adjustment bolt on

bell housing.

Notice: To ensure proper performance and maximum service life

for the CRD40, it is suggested that a program of regular inspec-

tion, testing, maintenance and cleaning be utilized. Annual

inspection and maintenance is recommended.

Disassembly

1. Before starting disassembly remove line pressure from control.

2. Measure distance adjustment bolt protrudes from bell housing.

Loosen lock nut on adjustment bolt and turn adjustment bolt out

of bell housing only to remove spring tension. DO NOT REMOVE

ADJUSTMENT BOLT, SPACER OR lock nut FROM BELL

HOUSING.

3. Unscrew bell housing counterclockwise and remove spring,

spring disc and friction ring.

4. Remove cartridge assembly from valve body by gripping

retaining bolt with pliers and pulling outward away from valve

body.

Reassembly

1. If possible, flush any debris out of valve body by allowing some

water flow while CRD40 is apart.

2. Replace old cartridge assembly with new cartridge assembly.

Carefully push new cartridge assembly into body making sure O-

rings seal tight against both cartridge and body. A small amount

of waterproof grease on O-rings may help cartridge assembly slip

into place.

3. Replace friction ring, spring, spring disc and bell housing with

adjustment bolt in place in order shown on drawing. Friction ring

must be installed as shown in diagram to avoid damage.

4. Turn adjustment bolt into bell housing to original measured set-

ting.

5. After remaining components of control valve pilot system and

main valve are serviced, recheck pressure setting of CRD40 with

flow through the valve. To readjust outlet pressure, loosen outer

lock nut and turn adjustment bolt clockwise (into bell housing) to

raise outlet pressure setting, turn adjustment bolt counterclock-

wise (out of bell housing) to lower outlet pressure setting.

INSTALLATION / OPERATION / MAINTENANCE

Troubleshooting

1

⁄

2

”

&

3

⁄

4

”

CRD40 Repair Kit Part Number 20348406K