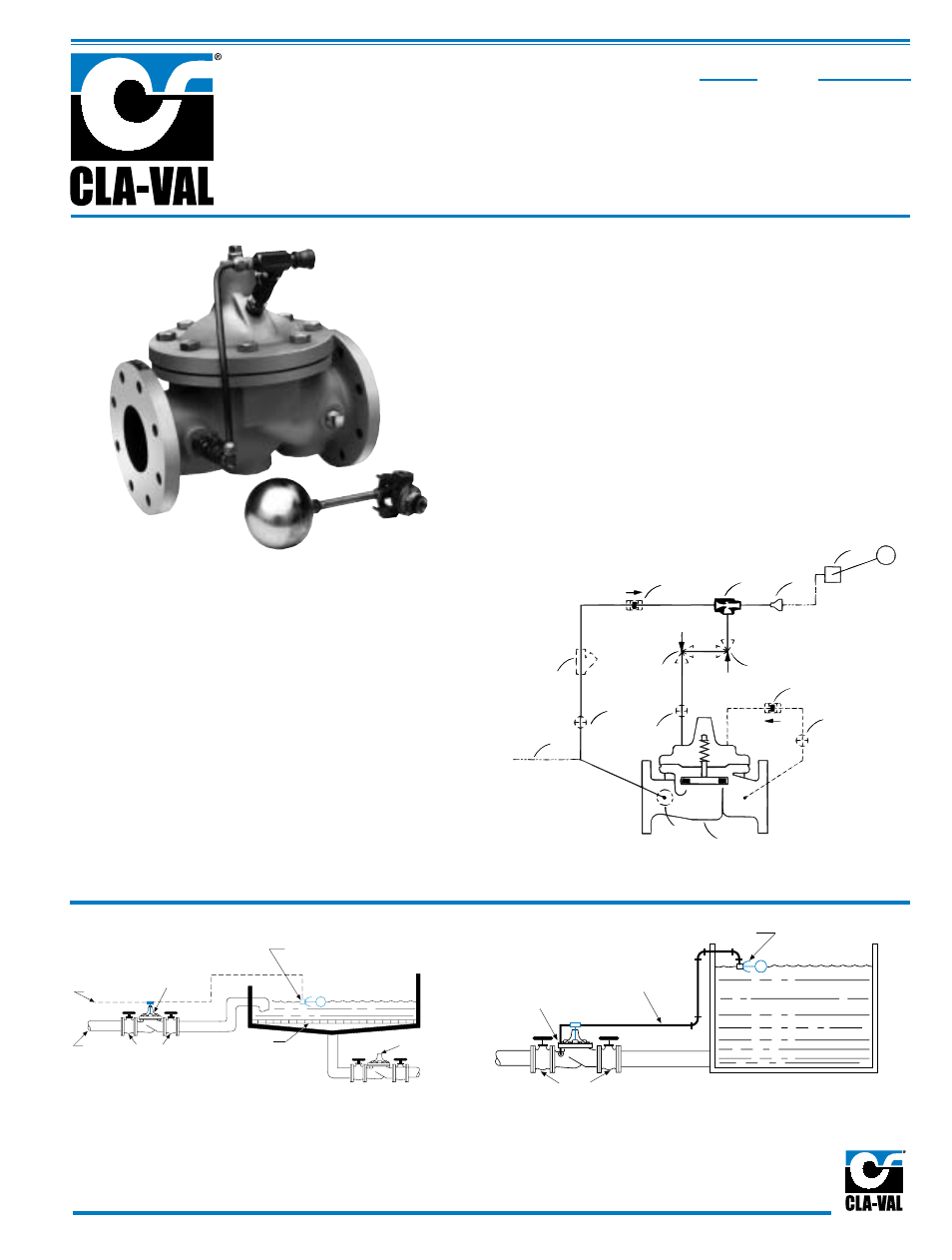

Float valve, Model, Typical applications – Cla-Val 129-01/629-01 User Manual

Page 5: Schematic diagram, Optional features

Note: We recommend protecting tubing and

valve from freezing temperatures.

Independent

Operating

Pressure

CLA-VAL

129-01/629-01

Float Valve

CFM2

Float Control

Filter

Isolation

Valves

Raw Water

Inlet

CLA-VAL 49-01/649-01

Rate-of Flow Controller

Isolation

Valves

TANK

CLA-VAL

129-01/629-01

Control Piping

(Not Furnished)

Float Control

4

3

2

D1

Y

B

F

INDEPENDENT

OPERATING

PRESSURE

INLET

OUTLET

A

1

D3

D2

C

B

S

MODEL

Float Valve

Typical Applications

Piping and Tank Sizing

Install valve and control as shown in the diagram above. The

float control should be located in a still liquid surface. If it is

necessary to obtain this condition, a stilling well should be

constructed. Mount the control on the connecting piping with

the outlet port at the desired high water level.

Filter Liquid Level Control

Maintains constant level in rapid sand filter.

Usually requires the use of an independent

operating pressure as shown.

Schematic Diagram

Item Description

1

Hytrol (Main Valve)

2

X47A Ejector

3

Bell Reducer

4

CFM2 Float Control

Optional Features

Item Description

A

X46A Flow Cleaner Strainer

B

CK2 (Isolation Valve)

C

CV Flow Control (Closing)

D

Check Valves With Isolation Valve

F

Independent Operating Pressure

S

CV Flow Control (Opening)

Y

X43 "Y" Strainer

• Accurate and Repeatable Level Control

• Proportional Flow

• Reliable Hydraulic Operation

• Drip Tight Positive Shut-off

• Completely Automatic Operation

The Cla-Val Model 129-01/629-01 Float Valve maintains a relatively

constant level in storage tanks and reservoirs by admitting flow into

the tank in direct proportion to the flow out of the tank. It is a

hydraulically operated, pilot controlled, diaphragm valve. The rotary

disc type float operated pilot control is installed at the high liquid level

in the reservoir and is connected via tubing or pipe to the main valve.

As the liquid level changes, the float control proportionally opens or

closes the main valve, keeping the liquid level nearly constant. If the

check feature option is added and a pressure reversal occurs, the

downstream pressure is admitted into the main valve cover chamber

and the valve closes to prevent return flow.

✣

The "D" feature on a vertically installed 6" and

larger valve must be horizontally installed.

129-01

629-01

TM

TM