Cfc2, Float control for closed tanks, Specifications – Cla-Val CFC2 User Manual

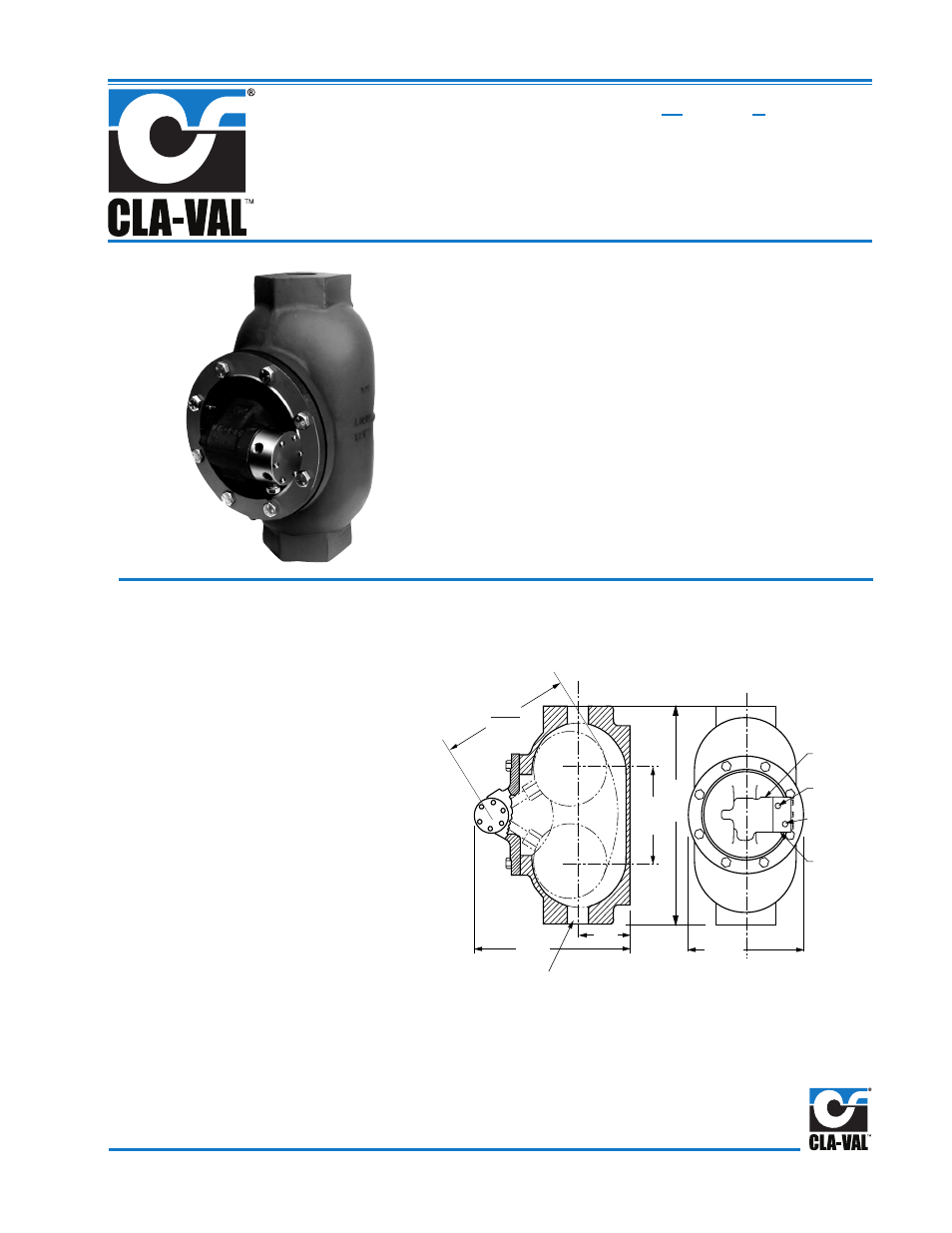

Page 2: Dimensions, Model

CFC2

Float Control

For Closed Tanks

Specifications

•

Accurate Liquid Level Control

•

Fully Hydraulic Operation

•

Simple Design, Easy Maintenance

•

No Lubrication Necessary

•

No Gears, No Mechanical Linkage Between

Valve and Control

The Cla-Val Model CFC2 Float Control is a float-actuated, multi-

port pilot control which provides non-modulating, two-position, on-

off operation. It is used primarily to operate remotely located Cla-

Val Valves requiring three-way or four-way pilot valve operation.

Designed for use in closed tanks, this control operates on a

minimum level change of approximately one inch. Maximum level

change of five and one-half inches is needed for full capacity.

Note: We recommend protecting the control tubing and valve from

freezing temperatures.

Dimensions

(In Inches)

Control Piping

Connections

1

⁄

8

" NPT

Reservoir

Connections

1" NPT

Pressure Rating 0-150 psi

Temperature

Rating

Water: to 180°F.

Materials

In contact with operating fluid:

Brass, Stainless Steel, Monel, with

Buna-N

®

Seals

Float chamber:

Cast Iron

Pilot valve housing:

Bronze

Materials in contact with operating fluid:

Brass, Stainless Steel, Monel with

Buna-N

®

Seals

Float ball:

Stainless Steel

Float arm:

Brass

Other material available:

Cast steel or aluminum chamber and

pilot valve housing. All stainless steel

Level Differential Approximately 1" minimum required to

change pilot valve operation. 5

5

⁄

16

"

required to develop full capacity.

Operating Fluids Clean liquids or gases compatible with

specified materials.

Shipping Weight 12 lbs.

Reservoir Connection

1" NPT (Typ. Both Ends 2 Places)

8.75

6.50

Port 2

1/8" NPT

(Typ. 4

Places)

Port 1

Drain

Supply

7.00

7.13

3.0

Flo

at

Tra

ve

l

5.3

2 11.

62

MODEL