N-124-02_2, Cla-val – Cla-Val 124-02/624-02 Quick Manual User Manual

Page 2

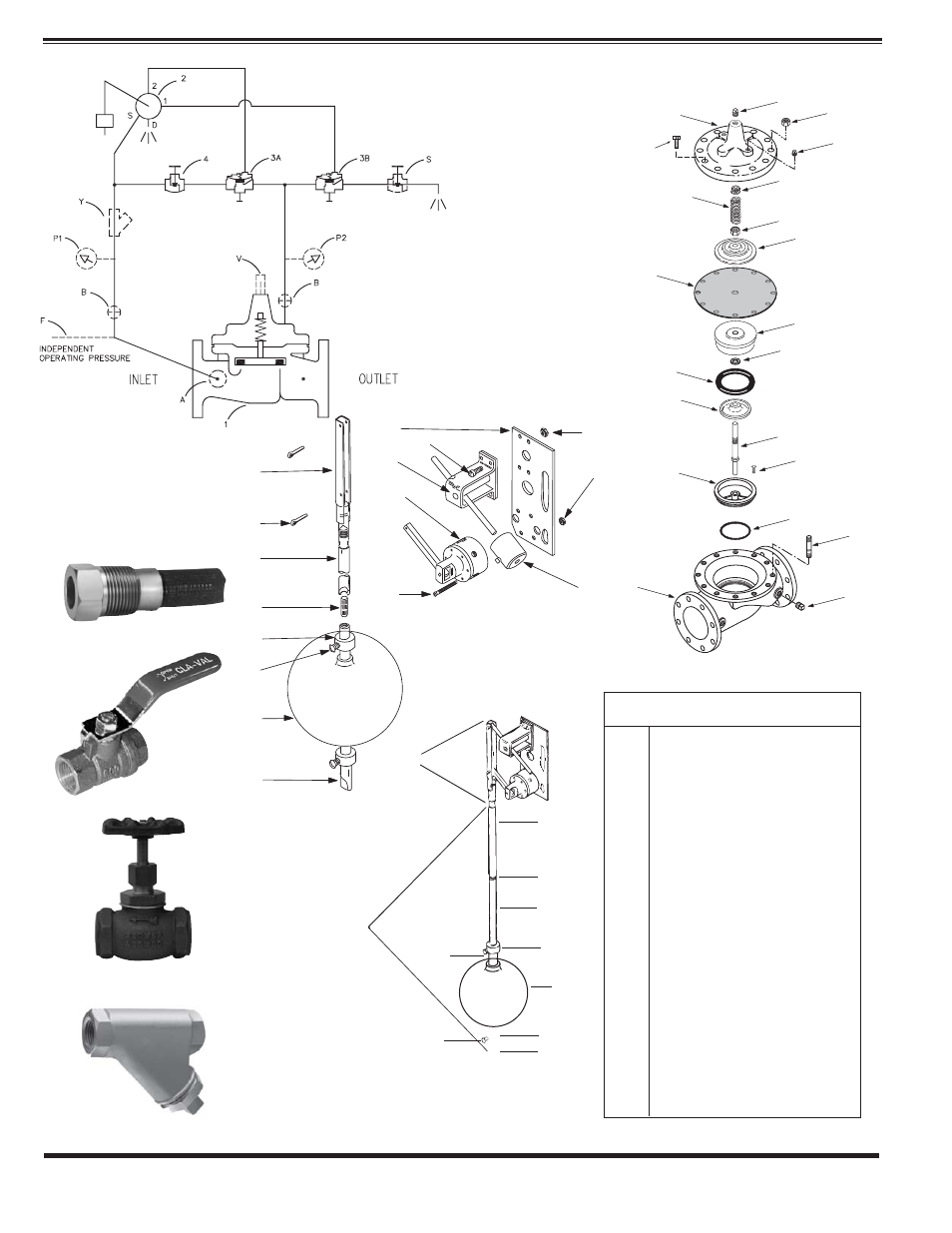

COVER

PIPE PLUG

COVER BEARING

SPRING

STEM NUT

DIAPHRAGM WASHER

DISC RETAINER

BODY

*

SPACER WASHERS

DISC GUIDE

SEAT

PIPE PLUG

STEM

SEAT O-RING

STUD

8" and Larger

*

DIAPHRAGM

*

DISC

*

Repair Parts

Seat Screw

8" and Larger

(Globe

or

Angle)

PIPE PLUG

HEX NUT

8" and Larger

Cover Bolt

6" and Smaller

BASIC COMPONENTS

1 100-01 Hytrol (Main Valve)

100-20 600 Series Hytrol (Main Valve)

2 CF1-C1 Float Control

3 100-01 Hytrol (Reverse Flow)

4 CGB Globe Valve

1

X46A

CK2

X43

A

B

CGB

4,S

Y

13

18

12

11

15

16

17

14

9

10

8

7

5

4

2

1

19

4

5

6

8

3

Float

Rod

Assembly

Pilot &

Bracket

Assembly

7

9

10

7

8

For a more detailed IOM Manual go to www.cla-val.com or contact a Cla-Val Regional Sales Office.

CLA-VAL

Copyright Cla-Val 2013 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

N-124-02/624-02 (R-1/2013)

124-02/624-02 SCHEMATIC

CF1-C1

HYTROL MAIN VALVE

2

ITEM

DESCRIPTION

1

Link Assembly

2

Cotter Pins (2 req'd)

3

Float Rod Assembly (2 ft. )

FLOAT ROD ASSY. BREAKDOWN

ITEMS 4 - 9

4

Upper Float Rod (1 ft.)

Upper Float Rod (2 ft.)

5

Stud (Req. for connecting upper and

lower rods

and one for each extension rod)

6

Extension Float Rod (1 ft.)

Extension Float Rod (2 ft.)

7

Stop Collar (2 req'd)

8

Set Screw (1 ea. stop collar)

9

Lower Float Rod (1 ft.)

Lower Float Rod (2 ft.)

10

Float Ball

11

Base and Mounting Plate

12

Pilot Valve Assembly CF1-Cl

13

Machine Screw 6/32 x 1 1/2"

(6 req'd.)

14

Hex Nut 6/32 (6 req)

15

Counter Balance Bracket Assy.

16

Machine Screw 10/32 x 9/16" (4 req'd.)

17

Hex Nut 10/32 (4 req'd.)

18

Counterweight (varies with rod

length, includes set screws)

19

Pilot & Bracket Assembly CF1-Cl

COUNTERWEIGHT NOT INCLUDED

OPTIONAL FEATURES

A X46A Flow Clean Strainer

B

CK2 (Isolation Valves)

F Independent Operating Pressure

P X141 Pressure Gauge

S CGB Globe Valve

V X101 Valve Position Indicator

Y X43 “Y” Strainer

*Repair Parts

NOTE:

1. A stilling well (Min. 8" I.D.)

must be provided around the

float.

2. Inspect float and float

assembly periodically.