Remote control valve – Cla-Val 7100 Technical Manual User Manual

Page 3

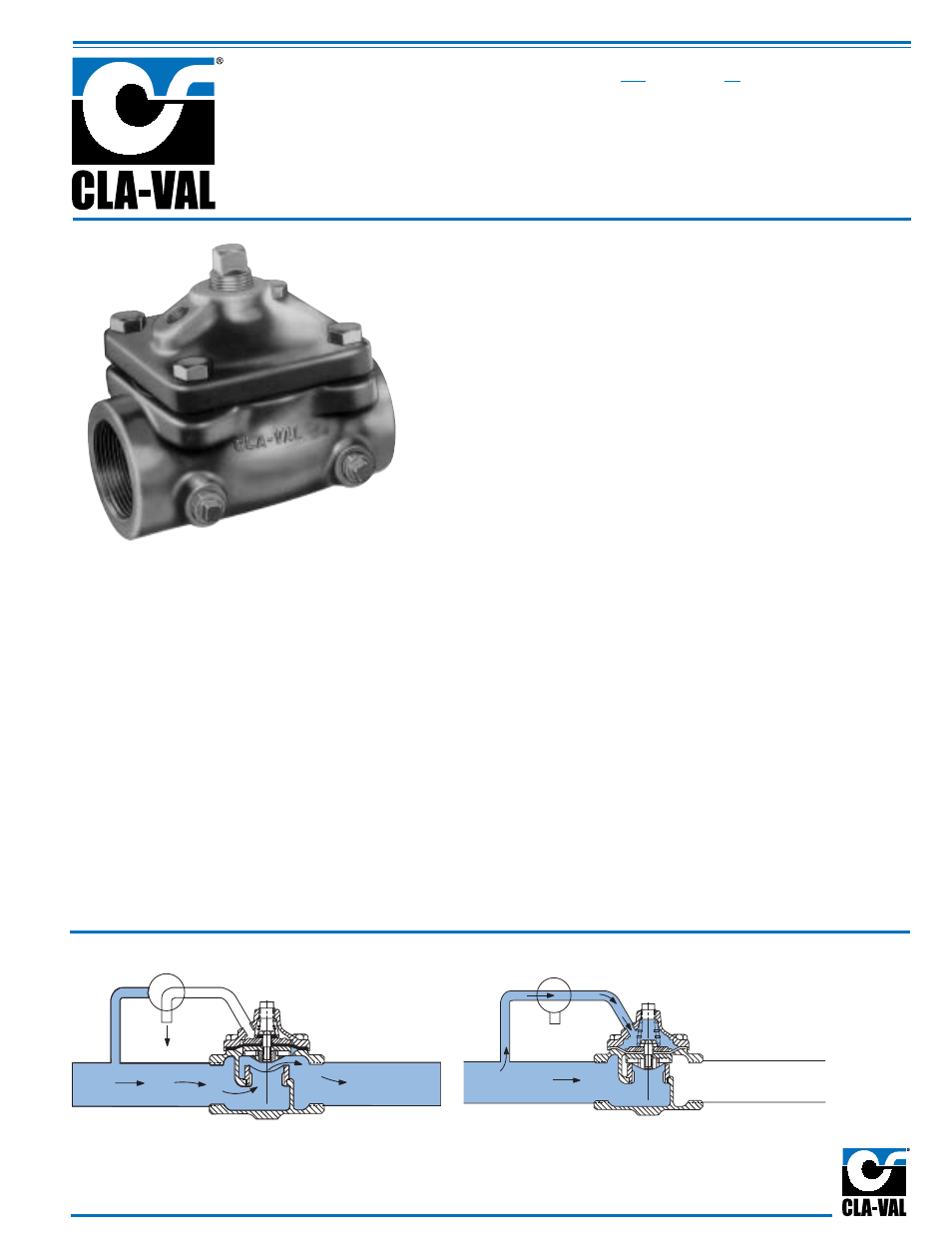

7100

Remote Control Valve

•

Packless design--no lubrication

•

Precisely engineered--close drip-tight

•

Full line-sized opening--low flow resistance

•

No internal or external orifice

•

Diaphragm is fully supported for longer life

•

Movable parts & seat ring replaceable without

removing valve from line

The Cla-Val Model 7100 Valve is a diaphragm actuated, hydraulically

operated valve designed for low original cost and long life. Its simple,

rugged construction allows it to perform dependably under the most

severe operating conditions. Its compact design makes it easy to install.

The 7100 Valve is ideal for any application where the need is for On-

Off control, the controlling medium of which is usually the liquid itself,

passing through a remote control. The control pressure, when applied

against the flexible diaphragm, produces a drip-tight seal between the

valve disc and its seat. In the open position, the diaphragm assembly

lifts to provide full flow.

The 7100 Valve provides all the advantages of an automatic control

valve at a cost comparable to manual valves of the same size and

quality.

Purchase Specification

Valve shall be full line size, diaphragm actuated. It shall be hydraulically

operated by employing the fluid flowing through it to open as well as

close the valve. The diaphragm shall be fabricated of nylon reinforced

synthetic rubber, and shall be fully supported in both the open and

closed positions and not be used as a disc or seating element. There

shall be no packing glands, internal orifice, or continuous bleeding.

The disc shall be synthetic rubber and have a cross section retained

on 31/2 sides. The disc shall close drip-tight against the valve seat.

The seat ring shall be replaceable and all necessary repairs shall be

possible without removing valve from the line. Valve shall be similar in

all respects to the Model 7100 Valve as manufactured by Cla-Val,

Newport Beach, California, or approved equal.

TM

TM

MODEL

Specifications

Sizes:

1-3 inch Threaded

2 and 3 inch Flanged

End Details:

125 ASA B16.1

Pressure Rating:

125 Class-175 psi Max.

Temperature Range:

Water : 125°F Max.

Petroleum Products:

-40°F to 125°F Max

Material Specification

Main Body and Cover:

Cast Iron ASTM A-48

Main Valve Trim:

Delrin (DuPont 500) with

Bronze seat (ASTM B-61)

Spring:

Stainless Steel AISI 302

Diaphragm and Disc:

Buna-N

®

Synthetic Rubber

Principle of Operation

VALVE OPEN

When pressure in diaphragm chamber is relieved to a zone

of lower pressure (usually atmosphere) the line pressure at

the valve seat opens the valve.

VALVE CLOSED

When pressure from the valve inlet (or an equivalent inde-

pendent operating pressure) is applied to the diaphragm

chamber the valve closes drip-tight.