Cla-Val 124-01/624-01 Quick Manual User Manual

Float valve, Model installation / operation / maintenance

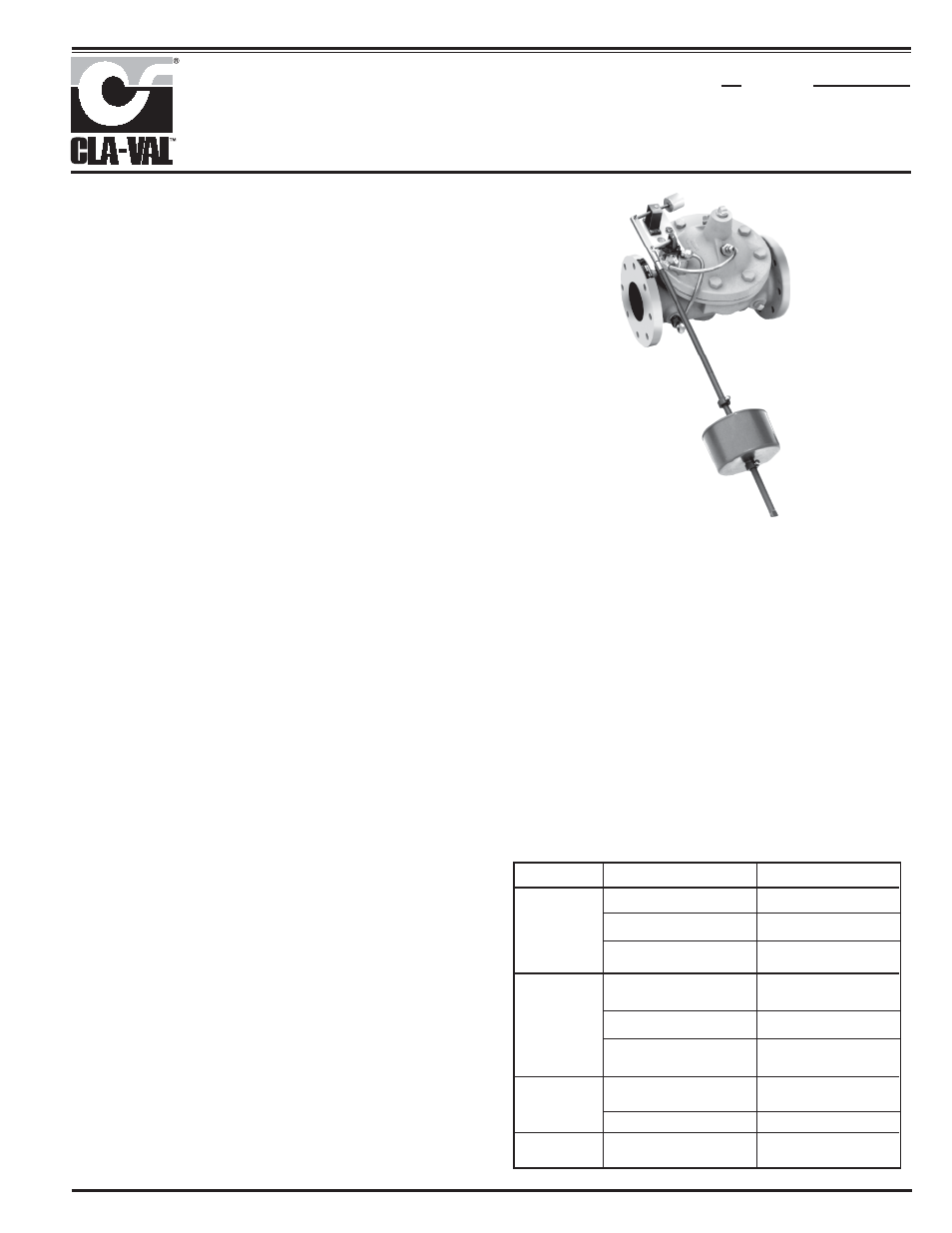

Float Valve

Description

The Cla-Val 124-01/624-01 is an automatic valve designed to open wide

when liquid level reaches a predetermined low point and to shut drip tight

when a predetermined high point is reached. It is a hydraulically operated,

pilot controlled valve. The Pilot Valve is actuated by a float ball to limit the

high and low liquid levels in the tank or reservoir by closing or opening the

main valve. High and low liquid levels are adjustable. The float control can

be remotely located only if the flowing line pressure at the valve inlet (in

psi) is equal to or greater than the elevation (in feet) from the main valve

to the float pilot control.

Installation

1. Allow sufficient room around the valve assembly for adjustments and

maintenance.

NOTE: BEFORE VALVE IS INSTALLED, THE PIPELINE SHOULD BE

FLUSHED OF ALL CHIPS, SCALE AND FOREIGN MATTER.

2. It is recommended that a gate or line block valve be installed upstream

of the 124-01/624-01 Float Valve to facilitate isolating the valve for mainte-

nance. If the discharge from the Float Valve is to atmosphere, an outlet

shutoff valve may not be required.

3. Place the 124-01/624-01 Float Valve in the line with flow through the

valve in the direction of flow arrows or by the inlet nameplate. Check all

fittings and hardware for proper makeup or apparent damage. Be sure

main valve cover bolts or cap screws are tight.

4. Cla-Val Valves operate with maximum efficiency when mounted in horizontal

piping with with the cover UP; however, other positions are acceptable.

Installation with the cover up is advisable to make internal parts readily

accessible for periodic inspection.

5

.

Caution must be taken in the installation of this valve to insure that

galvanic and/or electrolytic action does not take place. The proper use

of dielectric fittings and gaskets are required in all systems using dis-

similar metals.

6. When the valve is installed over water in the tank or reservoir mount the

valve to position the float rod and ball assembly (CF1-C1 item 3 ) vertically down

from the valve.

7. If the surface of the water in the tank is subject to waves by wind or by

valve discharge, a stilling well must be installed around the float ball

assembly. 8'' I.D. PVC pipe is suggested.

8. INITIAL ADJUSTMENT. See CF1-C1 on reverse side for proper assembly

of the float rod, ball and stop collars and threading into the Link Assembly.

Temporarily remove float. Adjust counterweight on the rod to balance the

weight of the link assembly and float rod assembly, less the float. Replace

float.

9. Move float rod to the "up" position. Adjust the upper stop collar on the

float rod assembly approximately three inches above the high water level

desired in the tank. Move float rod to “down” position. Adjust the lower stop

collar on the float rod assembly approximately three inches below the desired

low water level. Tighten stop collar screws on the CF1-C1.

124-01

624-01

Operation and Start-up

1. Prior to pressuring the valve assembly make sure the necessary

gauges to measure pressure in the system are installed as required by

the system engineer. A Cla-Val X101 Valve Position Indicator may be

installed in the center cover port to provide visual indication of the

valve stem during start-up.

CAUTION: During start-up and test procedures a large volume of water

may be discharged downstream. Check that the downstream venting is ade-

quate to prevent damage to personnel and equipment.

2. If the Pilot System shutoff valves (B) are installed, open valves.

(see schematic).

3. Very slowly open the upstream block valve.

4. While the tank is filling, the float rod and link assembly (CF1-C1 item 19)

can be moved slowly to the up position to manually close the main valve.

This operation tests the closure of the Float Valve and also will purge air

SYMPTOM

PROBABLE CAUSE

REMEDY

Continuous flow

Damaged valve diaphragm

Replace diaphragm

from float pilot

system discharge

port

Loose main valve (1) stem nut

Tighten stem nut

Damaged float pilot control (2)

Replace pilot valve

assembly (See P-CFI-CI)

Main Valve fails

Too low pressure differential

Restrict valve opening with

to close

across valve (Need 5 psi d Min

Cla-Val X102A flow limiting

under flowing conditions)

assembly (Contact Cla-Val)

Isolation valve in control tubing

Open isolation valve. clean

closed or clogged X46 strainer

strainer

Float and float rod fails to move

Free float mechanism

with liquid level change (stays in

down position)

Main Valve

Float and float rod fails to move

Free float mechanism

fails to open

with liquid level change (stays in

up position)

Inlet gate or block valve closed

Open valve

Main Valve

Air in cover

Bleed all air with float

Vibrates when

in the up position

closing

from the control lines and cover chamber. Carefully loosen tube fittings at

highest points and bleed air from system. Carefully loosen the plug at

top of main valve cover. If an indicator is installed, carefully loosen the

vent at top of indicator. If the valve is installed on its side loosen the

top 4 cover bolts to bleed air trapped in the cover. Bleed air from cover

and tighten plug. Tighten tube fittings.

Maintenance

1. Cla-Val Valves and Controls require no lubrication or packing and a

minimum of maintenance. However, a periodic inspection schedule

should be established to determine how the fluid handled is affecting the

efficiency of the valve assembly. Minimum of once per year.

2. Repair and maintenance procedures of the Cla-Val Hytrol main Valve

and the control components are included in a more detailed IOM manu-

al. It can be downloaded from our web site (www.cla-val.com) or obtained

by contacting a Cla-Val Regional Sales Office.

3. When ordering parts always refer to the catalog number and stock

number on the valve nameplate.

MODEL

INSTALLATION / OPERATION / MAINTENANCE