Cla-Val 7100 Quick Manual User Manual

Remote control valve

MODEL

INSTALLATION / OPERATION / MAINTENANCE

7100

Remote Control Valve

DESCRIPTION

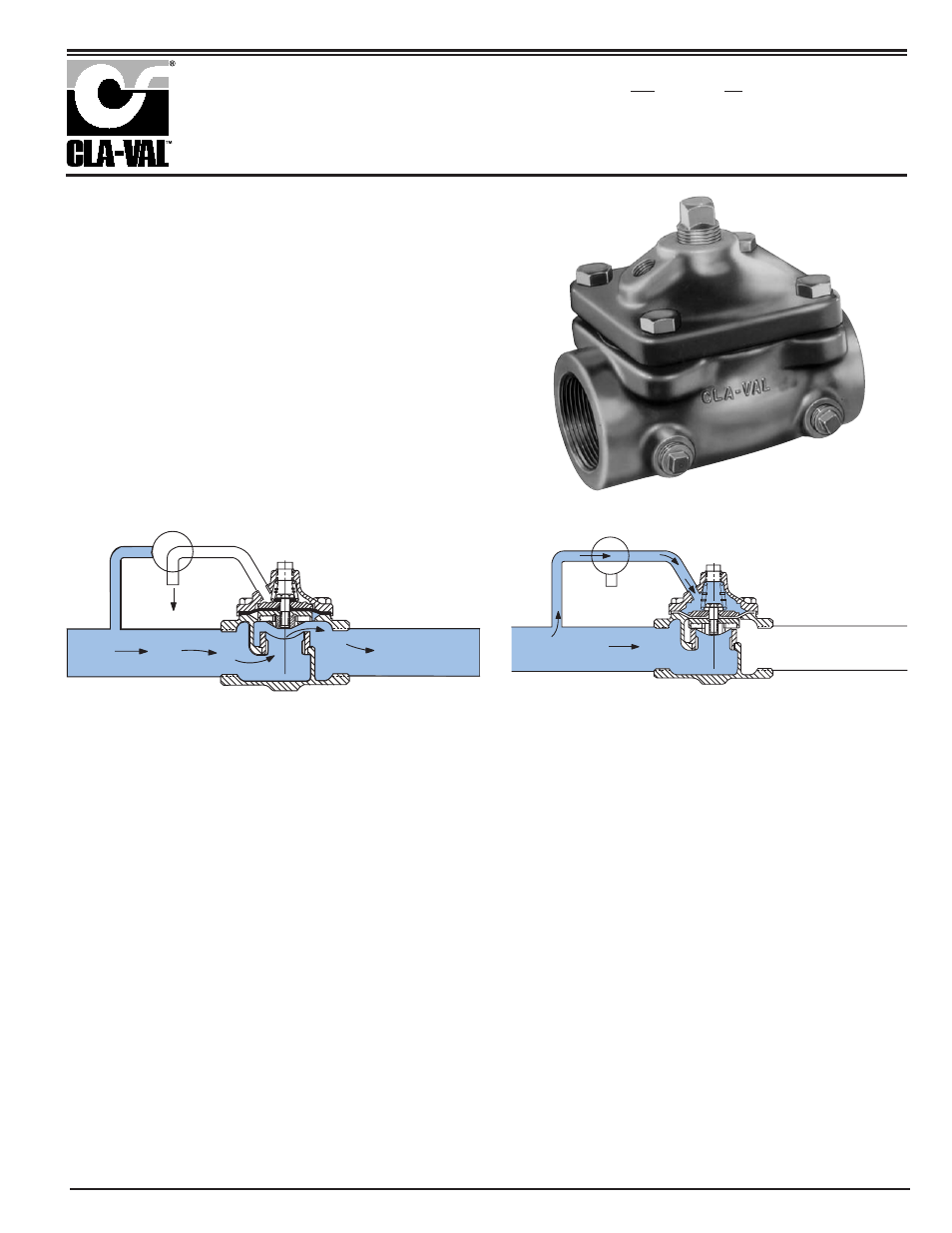

The Cla-Val 7100 Valve is a hydraulically operated, diaphragm

actuated, globe pattern valve. This valve consists of three

major components, the Body, with Fusion Bonded Epoxy

Coating Standard, Diaphragm Assembly and Cover. The

Diaphragm Assembly is the only moving part.

The Body contains a renewable seat insert.

The Diaphragm Assembly uses a diaphragm of nylon fabric

bonded with synthetic rubber. A synthetic rubber disc forms a seal

with the valve seat when pressure is applied above the

diaphragm. The Diaphragm Assembly forms a sealed chamber

in the upper portion of the valve, separating operating pressure

from line pressure.

OPERATION

When equipped with a three-way control valve the Cla-Val 7100

Valve either opens wide or closes tight.

VALVE OPEN

When pressure in diaphragm chamber is relieved to a zone

of lower pressure (usually atmosphere) the line pressure at

the valve seat opens the valve.

VALVE CLOSED

When pressure from the valve inlet (or an equivalent inde-

pendent operating pressure) is applied to the diaphragm

chamber the valve closes drip-tight.

INSTALLATION

1. Before valve is installed, pipe lines should be flushed of

all chips, scale and foreign matter.

2. Place valve in the line with flow through the valve in the

direction indicated on inlet plate or by flow arrows.

3. Allow sufficient room around valve to make adjust-

ments, and for disassembly.

4. Cla-Val 7100 Valves operate in any position.

5. If a pilot control system is installed with the 7100 Valve,

use care to prevent damage. If necessary to remove fittings

or tubing, be sure they are kept clean and replaced exact-

ly as they were.

6. After the valve is installed and the system is first pres-

surized, vent air from the cover chamber and tubing by

loosening fittings at all high points.

MAINTENANCE

Cla-Val 7100 Valves require no lubrication or packing and a

minimum of maintenance.

Disassembly

The inspection or maintenance of the 7100 Valve can be

accomplished without removal from the line. After pressure

has been shut off and the pressure released from the valve

and cover chamber, unscrew cover bolts and remove

Cover, Spring and Diaphragm Assembly. Remove seat

only if damage is evident. Check Disc for excessive wear

or embedded particles.

Reassembly

To reassemble reverse the order of disassembly.