Cla-Val 100-02 Quick Manual User Manual

Powertrol valve, Model installation / operation / maintenance

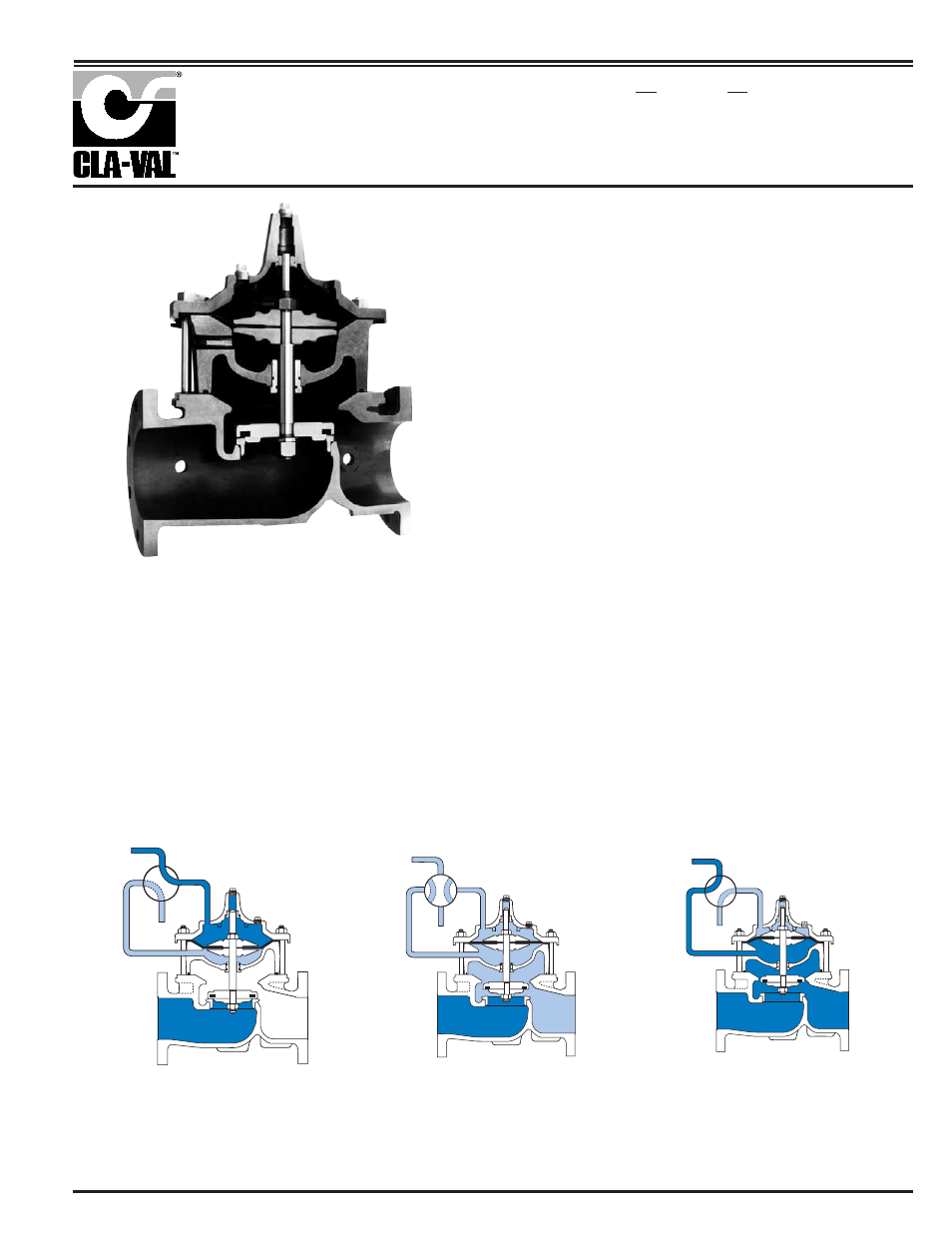

Principle of Operation

Powertrol Valve

100-02

DESCRIPTION

This manual contains information for installation, operation and main-

tenance of the Cla-Val Co. 100-02 Powertrol, an automatic valve

designed for use where independent operating pressure is desired,or

when line fluid is unsuitable as an operating medium.

This valve is a hydraulically operated, diaphragm type, globe or angle

pattern valve. it is single seated and incorporates into its design two

operating chambers sealed from one another by a flexible synthetic

rubber diaphragm. Pressure applied to the upper chamber closes the

valve; when applied to the lower chamber, it opens the valve.

With proper pilot controls, the valve can be held in any intermediate

position between fully open and tightly closed.

INSTALLATION

Allow sufficient room around the valve assembly to make adjustments

and for disassembly.

NOTE: BEFORE THE VALVE IS INSTALLED, PIPE LINES

SHOULD BE FLUSHED OF ALL CHIPS, SCALE AND FOREIGN

MATTER.

It is recommended that gate or block valves be installed on both the

upstream and downstream sides of the 100-02 to facilitate isolating

the valve for preventative maintenance.

Place the valve in the line with flow through the valve in the direction

indicated on the inlet name plate or by flow arrows.

Cla-Val Powertrol Valves operate with maximum efficiency when

mounted in horizontal piping with cover "UP,' however, other positions

are acceptable. Due to the size and weight of the cover and internal

assembly of 4" and larger valves, installation with the cover "UP" is

advisable. This makes periodic inspection of internal parts readily

accessible.

When a pilot control system is installed on the Powertrol Valve, use

care to prevent damage. If it is necessary to remove fittings or com-

ponents, be sure they are kept clean and replaced in the exact order

of removal.

After the valve is installed and the system is first pressurized, vent air

from the cover chamber and tubing by loosening fit" sings at all high

points.

Full Open Operation

When operating pressure below the

diaphragm is applied and operating, pressure

is relieved from the cover chamber, the valve

is held open, allowing full flow.

Modulating Action

The valve holds any intermediate position

when operating pressure is equal above and

below the diaphragm. A Cla-Val four-way pilot

control with "lock" position can maintain this

balance by stopping flow in the pilot control

system.

Tight Closing Operation

When pressure below the diaphragm is

relieved and operating pressure is applied to

the cover chamber, the valve closes drip-tight.

4 - Way Control

→

4 - Way Control

→

4 - Way Control with lock

→

TROUBLE SHOOTING

The following trouble shooting information deals strictly with the

Powertrol Valve; however some 'impossible causes" will refer to compo-

nents that may exist in the variety of control systems available for the

valve. All trouble shooting is possible without removing the valve from

the line.

CAUTION: Extreme care should be taken when servicing the valve.

Gate or line block valves must be closed upstream and downstream of

the valve before starting disassembly. When there are no block or gate

valves to isolate the Powertrol Valve it should be realized that the valve

cannot be serviced under pressure. Steps must be taken to remedy this

situation before proceeding.

1.

2.

3.

4.

5.

6.

MODEL

INSTALLATION / OPERATION / MAINTENANCE

(Full Internal Port)