Available sizes, Materials, Pressure ratings – Cla-Val 138-01/638-01 User Manual

Page 8

Specifications

Model 100-01

Viton

®

Rubber Parts - suffix KB

Optional diaphragm, disc and o-ring fabri-

cated with Viton

®

synthetic rubber. Viton

®

is

well suited for use with mineral acids, salt

solutions, chlorinated hydrocarbons, and

petroleum oils; and is primarily used in high

temperature applications up to 250° F. Do

not use with epoxy coatings above 175° F.

Epoxy Coating - suffix KC

This option NSF 61 Listed and FDA

approved, fusion bonded epoxy coating is

for use with cast iron, ductile iron or steel

valves. This coating is resistant to various

water conditions, certain acids, chemicals,

solvents and alkalies. Epoxy coatings are

applied in accordance with AWWA coating

specifications C116-03.

Do not use with temperatures above 175° F.

Dura-Kleen® Stem - suffix KD

This stem is designed for applications

where water supplies containing dissolved

minerals create deposits that build-up on a

standard stem and hamper valve opera-

tion. A patented, self-cleaning design on

the stem allows all valve sizes to operate

freely in the harshest conditions.

Delrin

®

Sleeved Stem - suffix KG

The Delrin

®

sleeved stem is designed for

applications where water supplies contain

dissolved minerals which can form

deposits that build up on the valve stem

and hamper valve operation. Scale build-

up will not adhere to the Delrin

®

sleeve

stem. Delrin

®

sleeved stems are not rec-

ommended for valves in continuous opera-

tion where differential pressures are in

excess of 80 psi (2" and larger Hytrol valves).

Heavy Spring - suffix KH

The heavy spring option is used in applica-

tions where there is low differential pres-

sure across the valve, and the additional

spring force is needed to help the valve

close. This option is best suited for valves

used in on-off (non-modulating) service.

Anti-Cavitation Trim - suffix KO

Anti-Cavitation Trim components consist of

a stainless steel radial slotted disc guide

and seat. This system is used when high

differentials are present across the valve.

Water Treatment Clearance - suffix KW

This additional clearance is beneficial in

applications where water treatment com-

pounds can interfere with the closing of the

valve. The smaller outside diameter disc

guide provides more clearance between

the disc guide and the valve seat. This

option is best suited for valves used in on-

off (non-modulating) service.

For assistance in selecting appropriate valve options or valves manufactured with special design requirements, please contact

our Regional Sales Office or Factory.

Available Sizes

Pattern

Threaded

Flanged

Grooved End

Globe

3

⁄

8

" - 3"

1

1

⁄

2

" - 36"

1

1

⁄

2

"-2"- 2

1

⁄

2

"- 3"- 4"- 6"- 8"

Angle

1" - 3"

1

1

⁄

2

" - 16" & 24"

2" - 3" - 4"

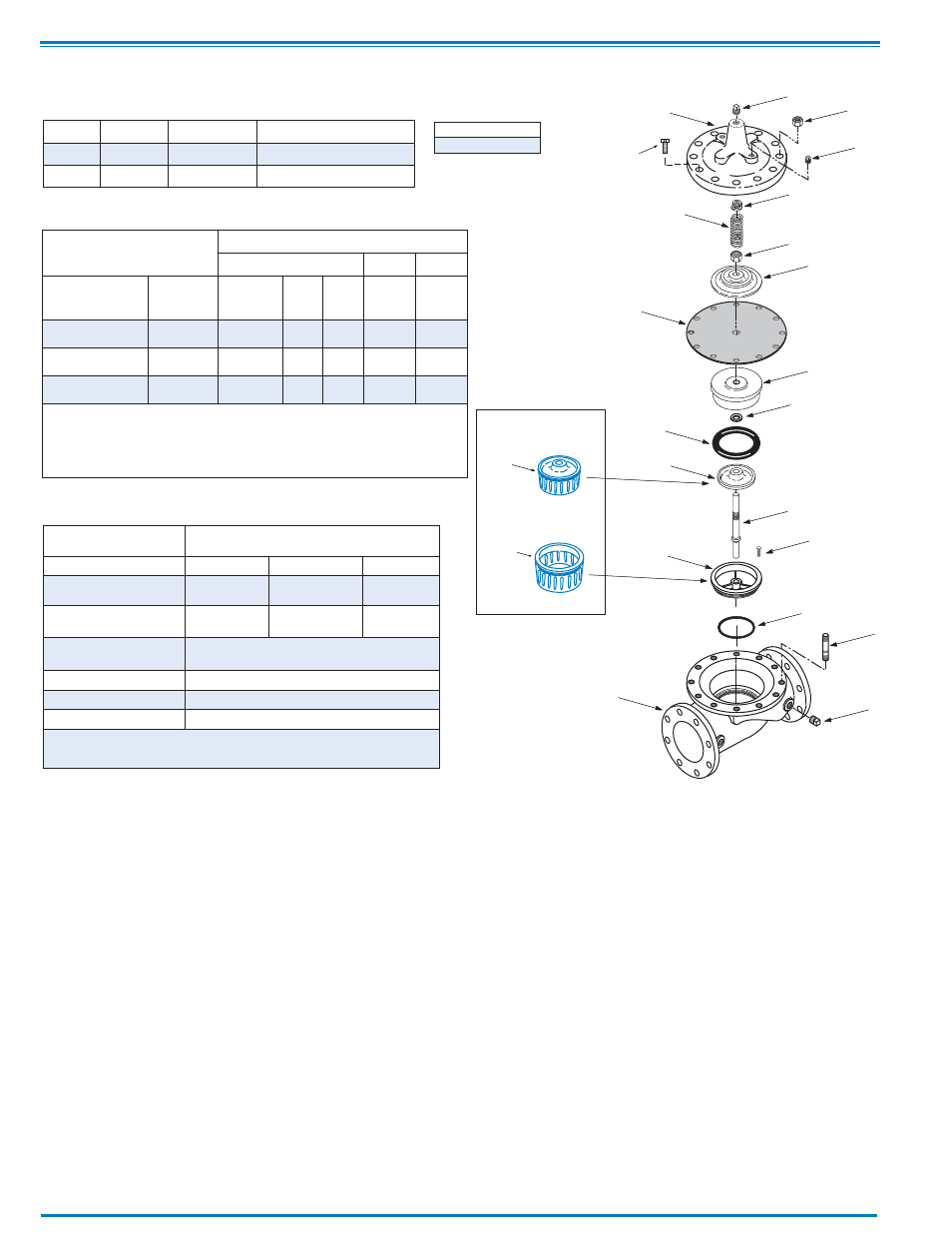

COVER

PIPE PLUG

COVER BEARING

SPRING

STEM NUT

DIAPHRAGM WASHER

DISC RETAINER

BODY

*

SPACER WASHERS

DISC GUIDE

SEAT

PIPE PLUG

STEM

SEAT O-RING

STUD

8" and Larger

*

DIAPHRAGM

*

DISC

*

Repair Parts

Seat Screw

8" and Larger

(Globe

or

Angle)

PIPE PLUG

HEX NUT

8" and Larger

Cover Bolt

6" and Smaller

KO

DISC GUIDE

KO

SEAT

KO Anti-Cavitation

Trim Option

Component

Standard Material Combinations

Body & Cover

Ductile Iron

Cast Steel

Bronze

Available Sizes

3/8" - 36"

1" - 16"

1" -16"

Disc Retainer &

Diaphragm Washer

Cast Iron

Cast Steel

Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Bronze is Standard

Stainless Steel is optional

Disc

Buna-N

®

Rubber

Diaphragm

Nylon Reinforced Buna-N

®

Rubber

Stem, Nut & Spring

Stainless Steel

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Materials

Valve Body & Cover

Pressure Class

Flanged

Grooved Threaded

Grade

Material

ANSI

Standards*

150

Class

300

Class

300

Class

End‡

Details

ASTM A536

Ductile Iron B16.42

250

400

400

400

ASTM A216-WCB Cast Steel

B16.5

285

400

400

400

ASTM B62

Bronze

B16.24

225

400

400

400

Note:

* ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

‡ End Details machined to ANSI B2.1 specifications.

Valves for higher pressure are available; consult factory for details

Pressure Ratings

(Recommended Maximum Pressure - psi)

Operating Temp. Range

Fluids

-40° to 180° F