Cla-val, Model 90-99 dimensions, Pilot system specifications – Cla-Val 90-99 User Manual

Page 2: Materials, Pressure ratings

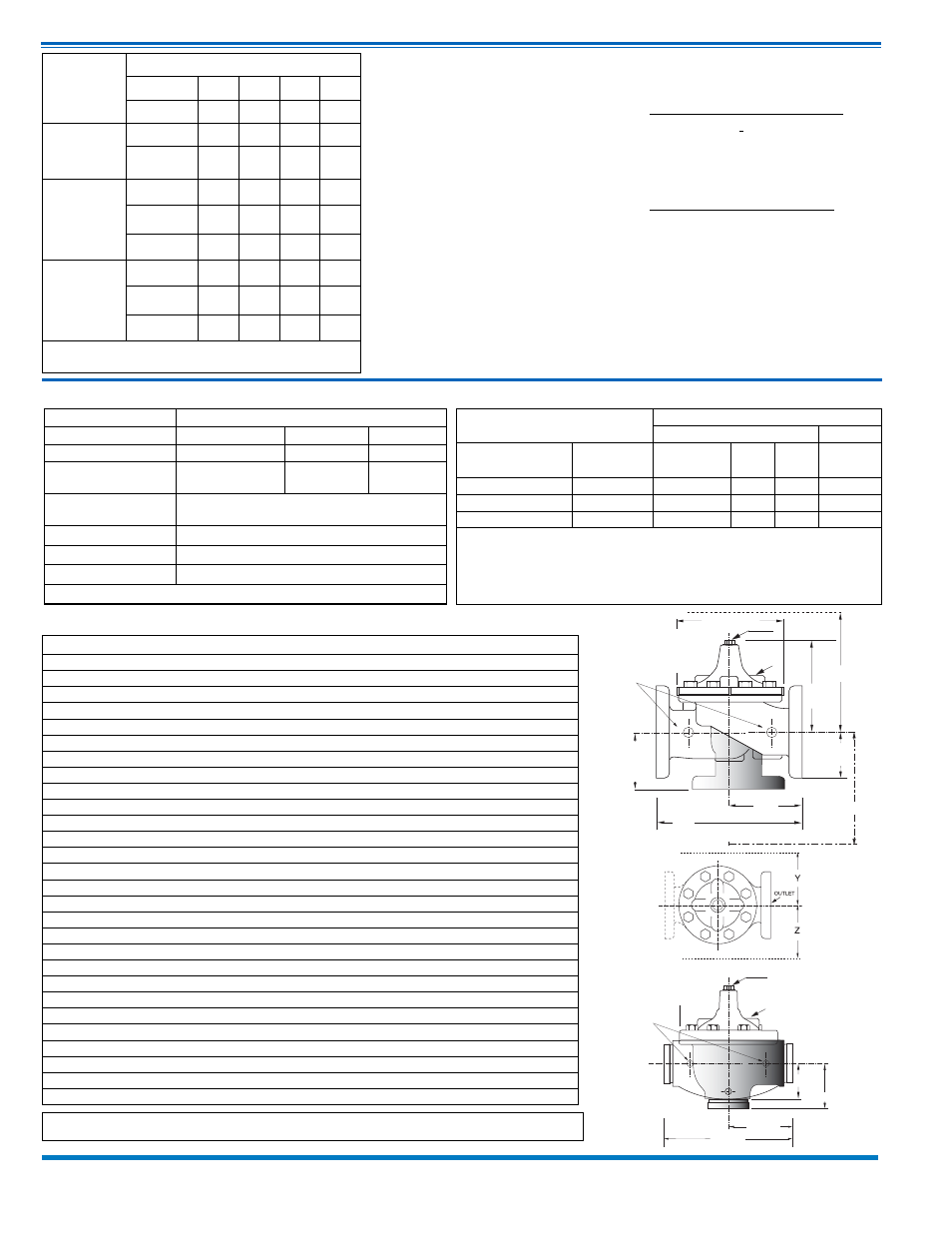

Model 90-99 Dimensions

(In Inches)

Materials

Standard Pilot System Materials

Pilot Control: Bronze ASTM B62

Trim: Stainless Steel Type 303

Rubber: Buna-N

®

Synthetic

Rubber

Optional Pilot System Materials

Pilot Systems are available with

optional Aluminum, Stainless Steel or

Monel materials.

Note: Available with remote sensing control

Pilot System Specifications

Adjustment Ranges

CRD

2 to

30 psi

15 to

75 psi

20 to 105 psi

30 to 300 psi*

*Supplied unless otherwise specified

Other ranges available, please consult

factory.

Temperature Range: Water: 180°

CLA-VAL

Copyright Cla-Val 2012 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

E-90-99 (R-01/2012)

100-01 Series is the full internal port Hytrol

For 100-01 basic valves • Suggested flow calculations are based on flow through Schedule 40 Pipe.

• Max continuous flow is approx. 20 ft/sec (6.1 meters/sec).

• Max intermittent is approx. 25 ft/sec (7.6 meters/sec).

Materials

Valve Body & Cover

Pressure Class

Flanged

Threaded

Grade

Material

ANSI

Standards*

150

Class

300

Class

End‡

Details

ASTM A536

Ductile Iron

B16.42

250

400

400

ASTM A216-WCB

Cast Steel

B16.5

285

400

400

ASTM B62

Bronze

B16.24

225

400

400

Note:

* ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

‡ End Details machined to ANSI B2.1 specifications.

Valves for higher pressure are available; consult factory for details

Pressure Ratings

(Recommended Maximum Pressure - psi)

G

GG

GGG

D

Inlet

DD

DDD

F

FF

X

100-01

Threaded &

Flanged

A

C

(MAX)

K

J

H

Inlet

Outlet

AA

AAA

B

(Diameter)

W

GGGG

DDDD

Inlet

AAAA

EE

K

J

H

Inlet

Outlet

Low Flow

By-Pass Valve

100-01 Grooved

Valve Size (Inches)

4

6

8

10

A Threaded

—

—

—

—

AA 150 ANSI

15.00

20.00

25.38

29.75

AAA 300 ANSI

15.62

21.00

26.38

31.12

AAAA Grooved End

15.00

20.00

25.38

—

B Dia.

11.50

15.75

20.00

23.62

C Max.

10.62

13.38

16.00

17.12

CC Max. Grooved End

9.31

12.12

14.62

—

D Threaded

—

—

—

—

DD 150 ANSI

7.50

10.00

12.69

14.88

DDD 300 ANSI

7.88

10.50

13.25

15.56

DDDD Grooved End

7.50

—

—

—

E

—

—

—

—

EE Grooved End

4.25

6.00

7.56

—

F 150 ANSI

4.50

5.50

6.75

8.00

FF 300 ANSI

5.00

6.25

7.50

8.75

G Threaded

—

—

—

—

GG 150 ANSI

5.00

6.00

8.00

8.62

GGG 300 ANSI

5.31

6.50

8.50

9.31

GGGG Grooved End

5.00

—

—

—

H NPT Body Tapping

.75

.75

1

1

J NPT Cover

Center Plug

.75

.75

1

1

K NPT Cover Tapping

.75

.75

1

1

Stem Travel

1.1

1.7

2.3

2.8

Approx. Ship Wt. Lbs.

140

285

500

780

X Pilot System

17

29

31

33

Y Pilot System

12

20

22

24

Z Pilot System

12

20

22

24

W Pilot System

34

34

36

38

*Globe Grooved Only

Component

Standard Material Combinations

Body & Cover

Ductile Iron Epoxy

Cast Steel

Bronze

Available Sizes

4" - 10"

4" - 10"

4" - 10"

Disc Retainer &

Diaphragm Washer

Cast Iron

Cast Steel

Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Bronze is Standard

Stainless Steel is Optional

Disc

Buna-N

®

Rubber

Diaphragm

Nylon Reinforced Buna-N

®

Rubber

Stem, Nut & Spring

Stainless Steel

For material options not listed, consult factory.

Many factors should be considered in sizing pressure reducing valves, including inlet pressure, outlet pressure

and flow rates. For sizing questions or cavitation analysis, consult Cla-Val with system details.

90-99

Valve

Selection

100-01 Pattern:

Globe (G), Angle (A),

End Connections:

Threaded (T), Grooved (GR), Flanged (F) Sizes

Inches

4

6

8

10

mm

100

150

200

250

Basic Valve

100-01

Pattern

G, A G, A G, A G, A

End Detail

F,

Gr

F,

Gr*

F,

Gr*

F

Suggested

Flow

(gpm)

Maximum

800

1800

3100

4900

Maximum

Intermittent

990

2250

3900

6150

Minimum

1

1

1

1

Suggested

Flow

(Liters/Sec)

Maximum

50

113

195

309

Maximum

Intermittent

62

142

246

387

Minimum

0.06

0.06

0.06

0.06

100-01 Series is the full internal port Hytrol.

For Lower Flows Consult Factory *Globe Grooved Only