Pressure ratings, Materials – Cla-Val 61-02KO/661-02KO Trim User Manual

Page 2

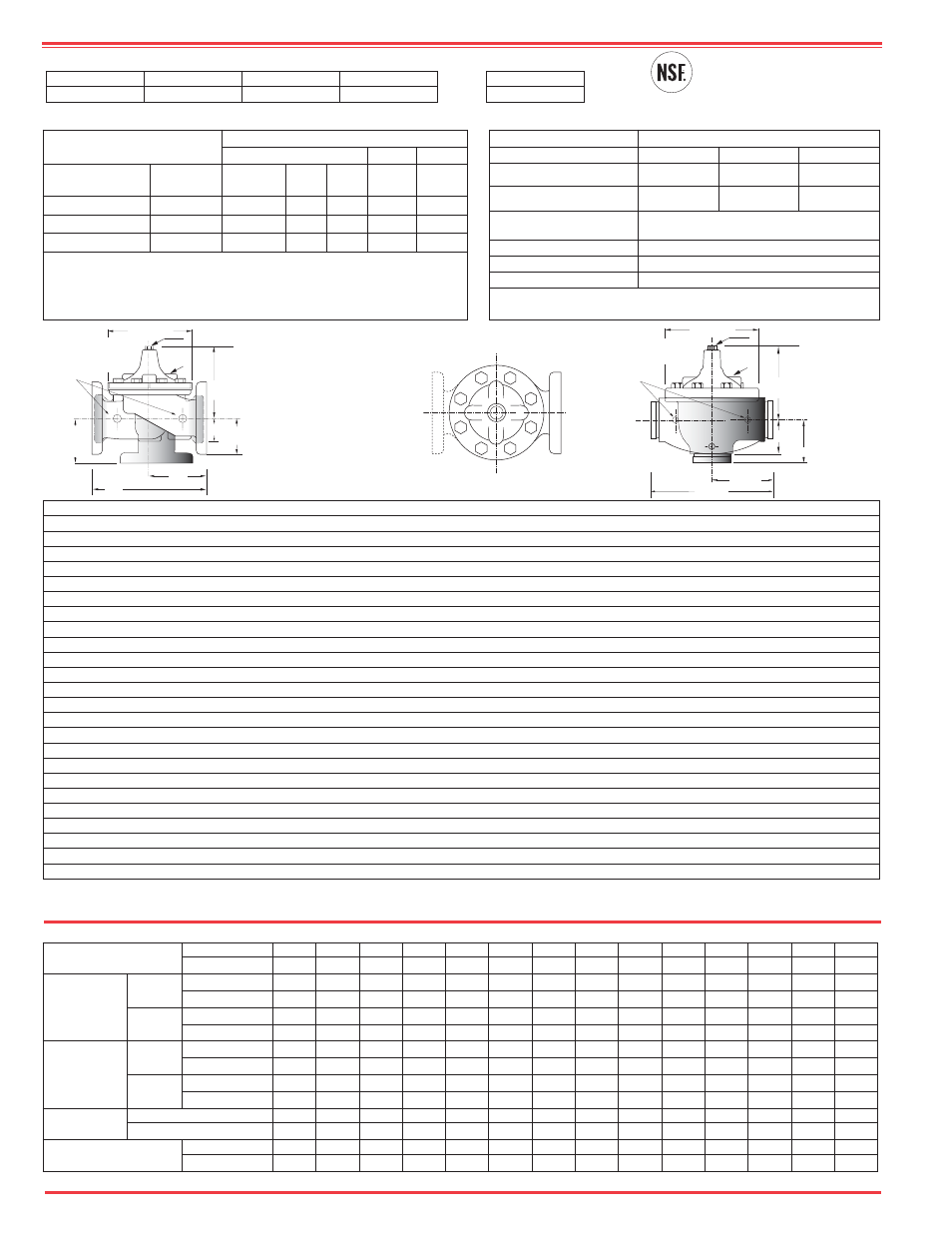

Model 100-01KO

Cla-Val Control Valves with KO ANTI-CAVITATION Trim operate with maximum efficiency when mounted in horizontal piping with the main valve cover Up. We recommend isolation valves

be installed on inlet and outlet for maintenance. Adequate space above and around the valve for service personnel should be considered essential. A regular maintenance program should

be established based on the specific application data. However, we recommend a thorough inspection be done at least once a year. Consult factory for specific recommendations.

GGGG

DDDD

Inlet

AAAA

100-01KO

Grooved

EE

CC

(MAX)

K

J

H

Inlet

Outlet

B

(Diameter)

G

GG

GGG

D

Inlet

DD

DDD

F

FF

100-01KO

Threaded &

Flanged

A

E

C

(MAX)

K

J

H

Inlet

Outlet

AA

AAA

B

(Diameter)

Pressure Ratings

(Recommended Maximum Pressure - psi)

For assistance in selecting appropriate valve options or valves manufactured with special design requirements, please contact our Regional Sales Office or Factory.

Functional Data

Model 100-01KO

Specifications

Operating Temp. Range

Pattern

Globe

Angle

Grooved End

Size

1" - 36"

1

1/2

" - 16"

1

1/2

" - 8"

APPROVED

(4" - 24")

Component

Standard Material Combinations

Body & Cover

Ductile Iron

Cast Steel

Bronze

Available Sizes

1" - 36"

1" - 16"

1" 16"

Disc Retainer &

Diaphragm Washer

Cast Iron

Cast Steel

Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Stainless Steel is Standard

Disc

Buna-N

®

Rubber

Diaphragm

Nylon Reinforced Buna-N

®

Rubber

Stem, Nut & Spring

Stainless Steel

For material options not listed consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Materials

Valve Size

Inches

1

1

⁄

2

2

2

1

⁄

2

3

4

6

8

10

12

14

16

20

24

36

mm.

40

50

65

80

100

150

200

250

300

350

400

500

600

900

C

V

Factor

Globe

Pattern

Gal./Min. (gpm.)

14

25

37

52

90

218

362

660

810

1100

1200

1950

3900

9150

Litres/Sec. (l/s.)

3.4

6.0

8.9

12.5

21.6

52

87

159

194

264

288

469

938

2199

Angle

Pattern

Gal./Min. (gpm.)

15

26

39

55

95

232

388

479

790

1075

1175

—

—

—

Litres/Sec. (l/s.)

3.6

6.2

9.4

13.2

22.8

56

93

115

190

258

282

—

—

—

Equivalent

Length of

Pipe

Globe

Pattern

Feet (ft.)

196

237

277

416

572

858

1315

2444

2118

1937

3022

4199

4532

3954

Meters (m.)

60

72

84

127

174

262

401

745

646

590

921

1280

1381

1205

Angle

Pattern

Feet (ft.)

171

219

250

372

514

757

1145

2133

2226

2021

3152

—

—

—

Meters (m.)

52

67

76

113

157

231

349

650

678

616

961

—

—

—

K Factor

Globe Pattern

30.6

26.1

24.3

29.3

29.0

25.5

27.7

41.0

27.7

22.8

31.4

29.5

28.9

15.1

Angle Pattern

26.7

24.1

21.8

26.2

26.0

22.5

24.1

35.8

29.1

23.8

32.8

—

—

Liquid Displaced from Cover

Chamber When Valve Opens

U.S. Gal.

0.2

.03

.04

.08

.17

.53

1.26

2.5

4.0

6.5

9.6

12

29

90

Litres

0.8

.12

.16

.30

.64

2.0

4.8

9.5

15.1

25.6

36.2

45.4

110

340

Note:

Consult Factory

on 10",12", 16"

angle pattern

Valve Body & Cover

Pressure Class

Flanged

Grooved Threaded

Grade

Material

ANSI

Standards*

150

Class

300

Class

300

Class

End‡

Details

ASTM A536

Ductile Iron B16.42

250

400

400

400

ASTM A216-WCB Cast Steel

B16.5

285

400

400

400

ASTM B62

Bronze

B16.24

225

400

400

400

Note:

* ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

‡ End Details machined to ANSI B2.1 specifications.

Valves for higher pressure are available; consult factory for details

Valve Size

(Inches)

1

1

1/4

1

1/2

2

2

1/2

3

4

6

8

10

12

14

16

18

20

24

30

36

A Threaded

7.25 7.25

7.25

9.38 11.00 12.50

—

—

—

—

—

—

—

—

—

—

—

—

AA 150 ANSI

—

—

8.50

9.38 11.00 12.00 15.00 20.00 25.38 29.75 34.00 39.00 41.38 46.00 52.00 61.50 63.00 76.00

AAA 300 ANSI

—

—

9.00 10.00 11.62 13.25 15.62 21.00 26.38 31.12 35.50 40.50 43.50 47.64 53.62 63.24 64.50 76.00

AAAA Grooved End

—

—

8.50

9.00 11.00 12.50 15.00 20.00 25.38

—

—

—

—

—

—

—

—

—

B Dia.

5.62 5.62

5.62

6.62

8.00

9.12

11.50 15.75 20.00 23.62 28.00 32.75 35.50 41.50 45.00 53.16 56.00 66.00

C Max.

5.50 5.50

5.50

6.50

7.56

8.19 10.62 13.38 16.00 17.12 20.88 24.19 25.00 39.06 41.90 43.93 54.60 61.50

CC Max. Grooved End

—

—

4.75

5.75

6.88

7.25

9.31 12.12 14.62

—

—

—

—

—

—

—

—

—

D Threaded

3.25 3.25

3.25

4.75

5.50

6.25

—

—

—

—

—

—

—

—

—

—

—

—

DD 150 ANSI

—

—

4.00

4.75

5.50

6.00

7.50 10.00 12.69 14.88 17.00 19.50 20.81

—

—

—

—

—

DDD 300 ANSI

—

—

4.25

5.00

5.88

6.38

7.88 10.50 13.25 15.56 17.75 20.25 21.62

—

—

—

—

—

DDDD Grooved End

—

—

—

4.75

—

6.00

7.50

—

—

—

—

—

—

—

—

—

—

—

E

1.12 1.12

1.12

1.50

1.69

2.06

3.19

4.31

5.31

9.25 10.75 12.62 15.50 12.95 15.00 17.75 21.31 24.56

EE Grooved End

—

—

2.00

2.50

2.88

3.12

4.25

6.00

7.56

—

—

—

—

—

—

—

—

—

F 150 ANSI

—

—

2.50

3.00

3.50

3.75

4.50

5.50

6.75

8.00

9.50 10.50 11.75 15.00 16.50 19.25 22.50 25.60

FF 300 ANSI

—

—

3.06

3.25

3.75

4.13

5.00

6.25

7.50

8.75 10.25 11.50 12.75 15.00 16.50 19.25 24.00 25.60

G Threaded

1.88 1.88

1.88

3.25

4.00

4.50

—

—

—

—

—

—

—

—

—

—

—

—

GG 150 ANSI

—

—

4.00

3.25

4.00

4.00

5.00

6.00

8.00

8.62 13.75 14.88 15.69

—

—

—

—

—

GGG 300 ANSI

—

—

4.25

3.50

4.31

4.38

5.31

6.50

8.50

9.31 14.50 15.62 16.50

—

—

—

—

—

GGGG Grooved End

—

—

—

3.25

—

4.25

5.00

—

—

—

—

—

—

—

—

—

—

—

H NPT Body Tapping

.375 .375

.375

.375

.50

.50

.75

.75

1

1

1

1

1

1

1

1

2

2

J NPT Cover Center Plug

.25

.25

.25

.50

.50

.50

.75

.75

1

1

1.25

1.5

2

1.5

1.5

1.5

2

2

K NPT Cover Tapping

.375 .375

.375

.375

.50

.50

.75

.75

1

1

1

1

1

1

1

1

2

2

Stem Travel

0.4

0.4

0.4

0.6

0.7

0.8

1.1

1.7

2.3

2.8

3.4

4.0

4.5

5.1

5.63

6.75

7.5

8.5

Approx. Ship Wt. Lbs.

15

15

15

35

50

70

140

285

500

780

1165

1600 2265 2982 3900 6200 7703 11720

Fluids

-40 to 180 F