Cla-val – Cla-Val 33A User Manual

Page 2

CLA-VAL

Copyright Cla-Val 2010 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

N-33A (R-10/2010)

PROBLEMS / SOLUTIONS

1. Leakage at Inlet Connection:

Tighten valve threaded connection. If leaks persist, remove

valve and seals threads with pipe sealant or tape.

2. Leakage at Cover/Body joint:

Tighten bolts per Table 2, replace gasket.

3. Small or Large Orifice Leakage:

Flush valve to remove debris. Disassemble and inspect both

seat, orifices and float for wear or damage. Replace as needed

with a float kit or seat kit

4. Small Orifice not Releasing Air Under Pressure:

Check that operating pressure does not exceed Working

Pressure on nameplate. Perform inspection step 3 and

disassemble valve if problem persists.

DISASSEMBLY

The valve can be disassembled without removing it from the

pipeline, or it may be removed from the line. All work on the

valve should be performed by a skilled mechanic. Special tools

are NOT required.

CAUTION: Drain the vale and de-pressurized before removing

the cover or pressure may causing injury.

1. Close inlet shut-off valve. Slowly open drain valve or remove

drain plug. Remove the covers bolts slowly.

2. Pry cover loose and lift off valve body.

3. Remove entire seat & float assemblies inspect for damage or

wear

4. Clean and inspect parts. Note: Shake float & if water inside

float replace it and worn parts as necessary.

NOTE:

Float Kit & Seat Kit includes cover gasket

REASSEMBLY

1. All parts must be cleaned and gaskets surfaces cleaned

with a stiff wire brush in the direction of the serration or

machine marks. Worn parts, gaskets and seal should be

replaced during reassembly.

2. Apply Loctite or similar Compound to threaded Connections

3. Stand valve body vertically. Insert entire delrin frame, seat &

float assembly into register. Move float up/down to insure

concentricity and no binding.

4. Lay new cover gasket on clean surface and apply a gasket

compound such as Permatex #80065 to both surfaces.

Assemble gasket and cover over bolt holes in body.

5. Insert lubricated bolts and tighten to the torques listed in

Table 2.

6. Place valve back in service. Refer to the installation

instruction. Slowly open inlet isolation valve.

PARTS AND SERVICE

Parts and service are available from your local representative

or the factory. Make note of the valve Model No. and Working

Pressure located on the valve nameplate.

BOLT SIZE

1/4”-20

5/16”-18

3/8”-24

7/16”-32

TORQUE (FT. LBS.)

6

11

19

30

TABLE 2. VALVE COVER BOLT TORQUES

Specifications

Pressure Ratings

Materials

500 psi Ductile Iron

Body and Cover:

Body and Cover

Ductile Iron

ASTM A536 65-45-12

500 psi Stainless Steel

Body and Cover

Body and Cover

Stainless Steel T303

600 psi Cast Steel

Body and Cover

Body and Cover

Cast Steel ASTM A 216 WCB

Note:

Readily available for seawater service and other

corrosive fluids applications Made of:

Monel - Bronze’s - Stainless Steel

Standard Internals

Float: Stainless Steel T304

Balance internals parts Stainless Steel and Delrin

Seals Nitrile Rubber or Viton (extra cost)

Temperature Range

Water to 180° F

Optional:

1. Fusion epoxy lined and coated at extra cost

2. For Well Service Install Throttling Device on the Outlet

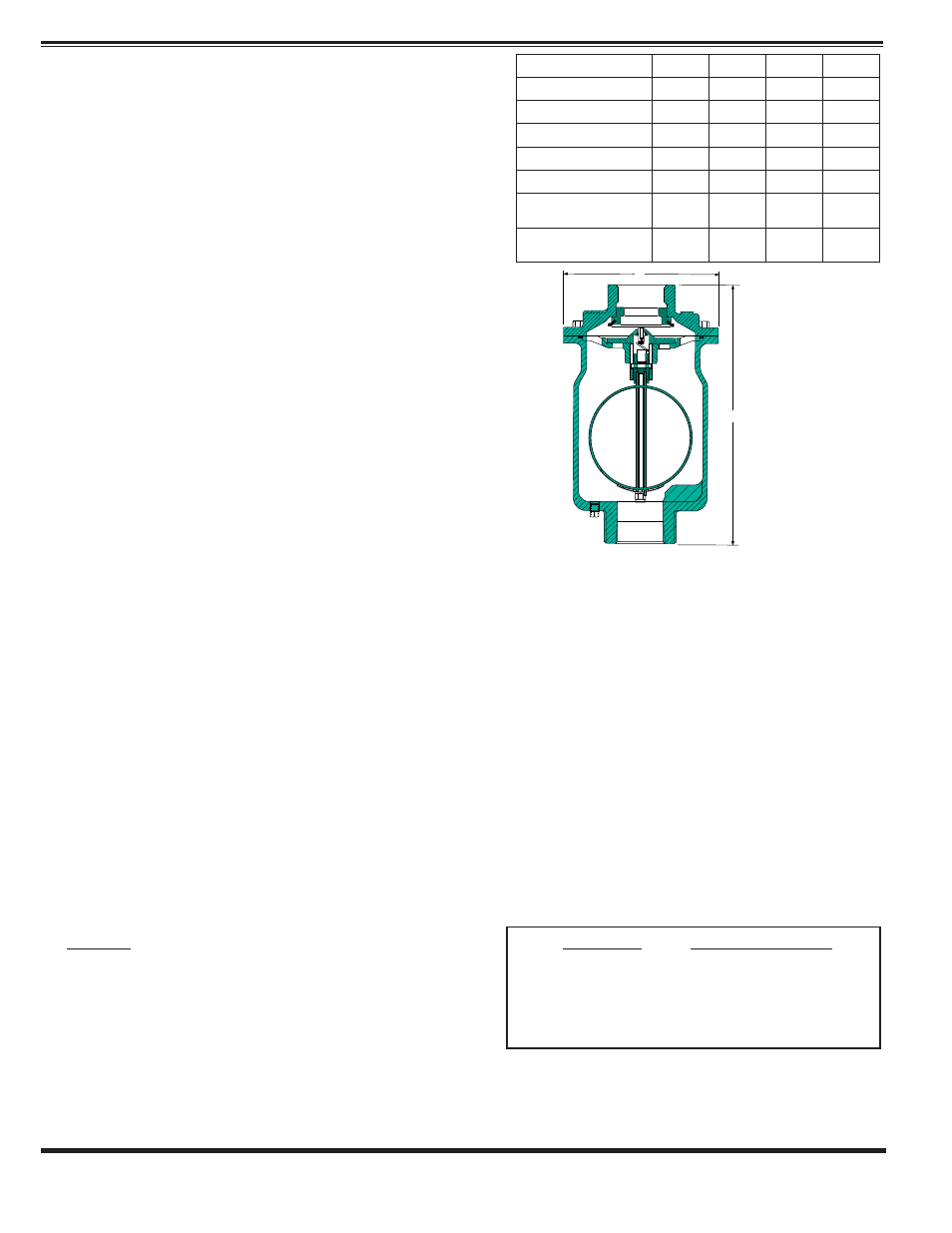

MODEL 33A - 1”,2”,3” and 4” SIZES

Single Body Combination Air Vacuum

Air Release Valve

Valve Size

1"

2"

3"

4"

A

9.10

12.44

12.75

12.75

B

6.25

7.50

9.00

9.00

Inlet (NPT)

1" NPT 2" NPT 3" NPT 4" NPT

Outlet (NPT)

1" NPT 2" NPT 4" NPT 4" NPT

Shipping Wt. (Lbs.)*

25

29

38

40

Max. Operating PSI

(Std. Orifice)

300

500

300

300

Max. Operating PSI

(with .076 Orifice)

300

500

450

450

*

Approximate

B

A

OUTLET

INLET

Available Flanged