E-60-32 4in & larger_2, Cla-val, Pilot system specifications – Cla-Val 60-32/660-32 User Manual

Page 4: When ordering, please specify, Wiring diagram

CLA-VAL

Copyright Cla-Val 2013 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

Auto

Off

Hand

L1

SW1

A

3CR3

L2

1CR

H

1CR

1CR

3CR1

N.C.

2CR

PVS

2CR

3CR

M

COM.

SW

2

N.O.

3CR

2

2CR

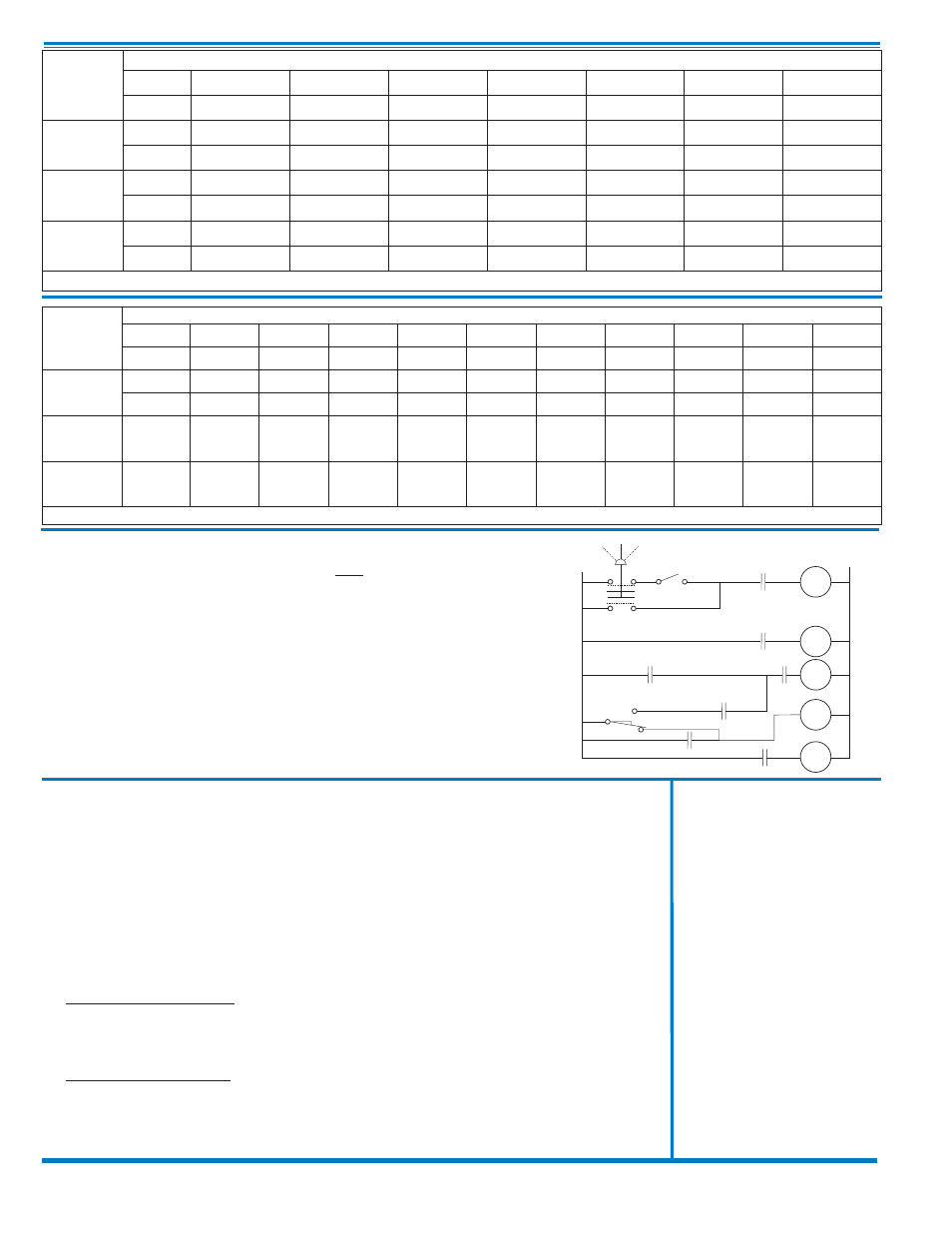

Auto-Off-Hand = Selector Switch

1CR = Relay, DPST Normally Open

2CR = Relay, DPST Normally Open

3CR = Relay, TPST Normally Open

SW1 = Switch, Remote Start/ Stop

SW2 = Switch, SPDT, Valve Limit Switch

PVS = Pilot Valve Solenoid

M =

Pump Motor Starter

Note:

SW2 and PVS supplied by Cla-Val

Co. All other electrical items supplied by

customer. SW2 is included in the X105L

switch assembly which is mounted on the

pump control valve cover.

Shown In Pump Off Position

Optional Model PC-1 Pump Control

Panel has flexible control settings for

maximum electrical interlock control. It is

pre-wired and ready for easy field hook-

up wiring. See E-PC-1 data sheet.

Pilot System Specifications

Adjustment Ranges

0 to 75 psi

20 to 105 psi

20 to 200 psi*

100 to 300 psi

*Supplied unless otherwise specified

Other ranges available, please consult factory

Temperature Range

Water: to 180°F Max

Materials

Standard Pilot System Materials

Pilot Control:

Bronze ASTM B62

Trim:

Stainless Steel Type 303

Rubber:

Buna-N

®

Synthetic Rubber

Optional Pilot System Materials

Pilot Systems are available with optional

Stainless Steel or Monel materials

Solenoid Contro

l

Body:

Brass ASTM B283

Enclosure:

General Purpose, Watertight 1,2,3,3S,4,4X

Optional: Class I, Division 2, Hazardous Locations

and Watertight Type 3, 3S, 4, 4X

Voltages:

100-240V / 50-60 Hz AC or DC

24-99V / 50-60Hz AC or DC

2-24VDC

Manual Operator Standard

Max. operating pressure differential: 350 psi

Coil:

Insulation molded Class

F

Watts AC

2

When Ordering,

Please Specify

1. Catalog No. 60-32 or

No. 660-32

2. Valve Size

3. Pattern - Globe or Angle

4. Pressure Class (Flanged)

5. Trim Material

6. Electrical Selection

7. Desired Options

8. When Vertically Installed

(Flow Direction)

Note: For optimum operation of built-in check feature, installation with valve stem vertically position is recommended.

E-60-32/660-32 (R-1/2013)

60-32

Valve

Selection

100-04 Pattern:

Globe (G), Angle (A),

End Connections:

Threaded (T), Flanged (F) Indicate Available Sizes

Inches

4

6

8

10

12

14

16

mm

100

150

200

250

300

350

400

Basic Valve

100-04

Pattern

G, A

G, A

G, A

G, A

G, A

G, A

G, A

End Detail

F

F

F

F

F

F

F

Suggested

Flow

(gpm)

Maximum

800

1800

3100

4900

7000

8400

11000

Maximum

Intermittent

990

2250

3900

6150

8720

10540

13700

Suggested

Flow

(Liters/Sec)

Maximum

50

113

195

309

442

530

694

Maximum

Intermittent

62

142

246

387

549

664

863

100-04 Series is the full internal port Hycheck.

660-32

Valve

Selection

100-23 Pattern:

Globe (G), Angle (A),

End Connections:

Flanged (F) Indicate Available Sizes

Inches

4

6

8

10

12

14

16

18

20

24

mm

100

150

200

250

300

350

400

450

500

600

Basic Valve

100-23

Pattern

G, A

G, A

G, A

G

G

G

G

G

G

G

End Detail

F

F

F

F

F

F

F

F

F

F

Suggested

Flow

(gpm)

Maximum

580

1025

2300

4100

6400

9230

9230

16500

16500

16500

Suggested

Flow

(Liters/Sec)

Maximum

37

65

145

258

403

581

581

1040

1040

1040

100-23 Series is the reduced internal port size version of the 100-04 Series.

Wiring Diagram