Installation/operation, Setting the breaker valve, Sewage applications – Cla-Val 38VB/AR Series User Manual

Page 3: Flushing procedure fig. 4

INSTALLATION/OPERATION

Installation of the vacuum breaker valve is important for

its proper operation. Valves must be installed in a vertical

position with the inlet down on high points of a pipeline or

tank, where vacuum conditions are anticipated. A full

ported shut-off valve, under the valve, should be installed

for future inspection or maintenance.

The vacuum breaker valve will open to allow air to re-

enter the pipeline or tank for any reason that the pipeline

or tank is drained. Allowing air re-entry will prevent vacu-

um forming that would otherwise cause pipeline or

tank to collapse and also prevent water column separa-

tions which can cause pressure surges and damage as

the water column rejoins.

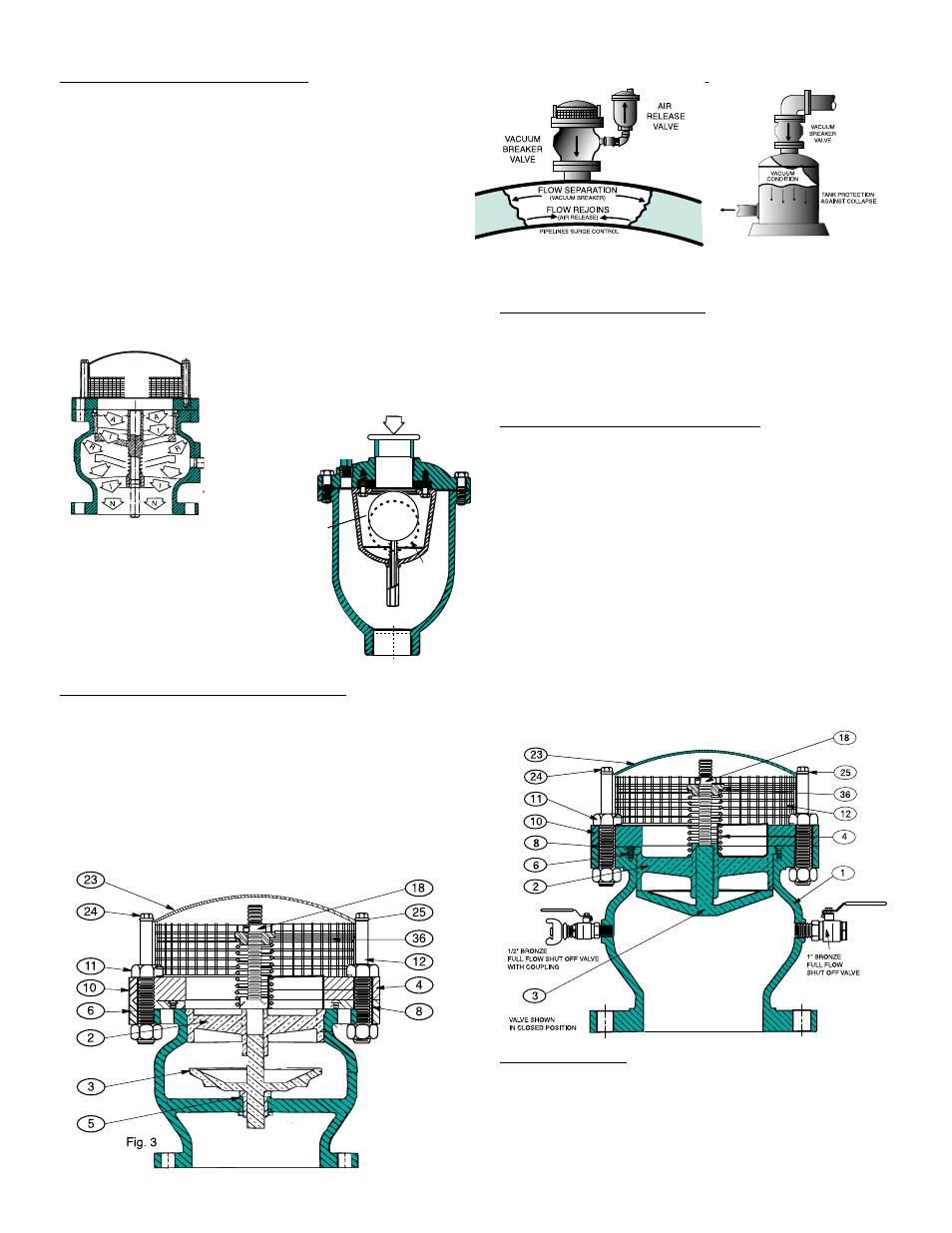

SETTING THE BREAKER VALVE

The standard vacuum breaker Fig.1 and Fig.1A above

are set from the factory to open between 1/4” & 1/2” PSI.

This is setting is not adjustable. The vacuum breaker having

an external spring for water or for sewage is set at the

factory per customers specification. After installation the

Vacuum breaker can be re-adjusted to suit actual operat-

ing conditions simply by tightening or loosening #18 seat

collar Fig 3.

SEWAGE APPLICATIONS

The Cla-Val Vacuum Breaker for sewage has clear flow

unobstructed body to prevent clogging. This valve is supplied

with (2) 1” full flow valves for flushing out the valve

periodically as may be required.

FLUSHING PROCEDURE FIG. 4

1. Shut the isolation valve under the vacuum breaker

(As provided by others).

2. Depressurize the vacuum breaker by slowly opening

one of the full flow valves mounted on the valve body.

3. Flush with pressurized water from a water tanker or

remove the vacuum from the pipeline or tank and take

it to the maintenance shop for cleaning.

4. During flushing, push down the external spring to

create a cleansing action around the plug #3 and thru

the sea. #2.

MAINTENANCE

Cla-Val Vacuum Breakers operate automatically and

no regular lubrication or maintenance is required.

A visual inspection annually to observe if any leakage

is occurring by simply removing the hood #22 will be

more than adequate.

Fig.4

TYPICAL INSTALLATION

VACUUM

BREAKER

LARGER

ORIFICE

STANDARD FLANGE STYLE

SMALL

ORIFICE

AIR RELEASE

OPEN

CLOSED

VACUUM

BREAKER

LARGE

ORIFICE

AIR

OUT

AIR

IN

Large

Orifice

Fig 1A

Fig 1.

STANDARD THREADED STYLE

ADJUSTABLE

Valve Shown in

Open Position

For Sewage