Cla-val – Cla-Val 582SWS Series User Manual

Page 4

Page 4

CLA-VAL

© 2004 Cla-Val Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

N-582 Series

2

5

4

10

1

FLOW

2

5

FLOW

4

1

8

9

ANSI CLASS 125

BOL

T

CIRCLE

7

3A

3B

4B

6A

6B

10

DETAIL

DESCRIPTION

Table 6A Check Valve Parts List

Sizes 18” & Larger Utilizes (2) Springs

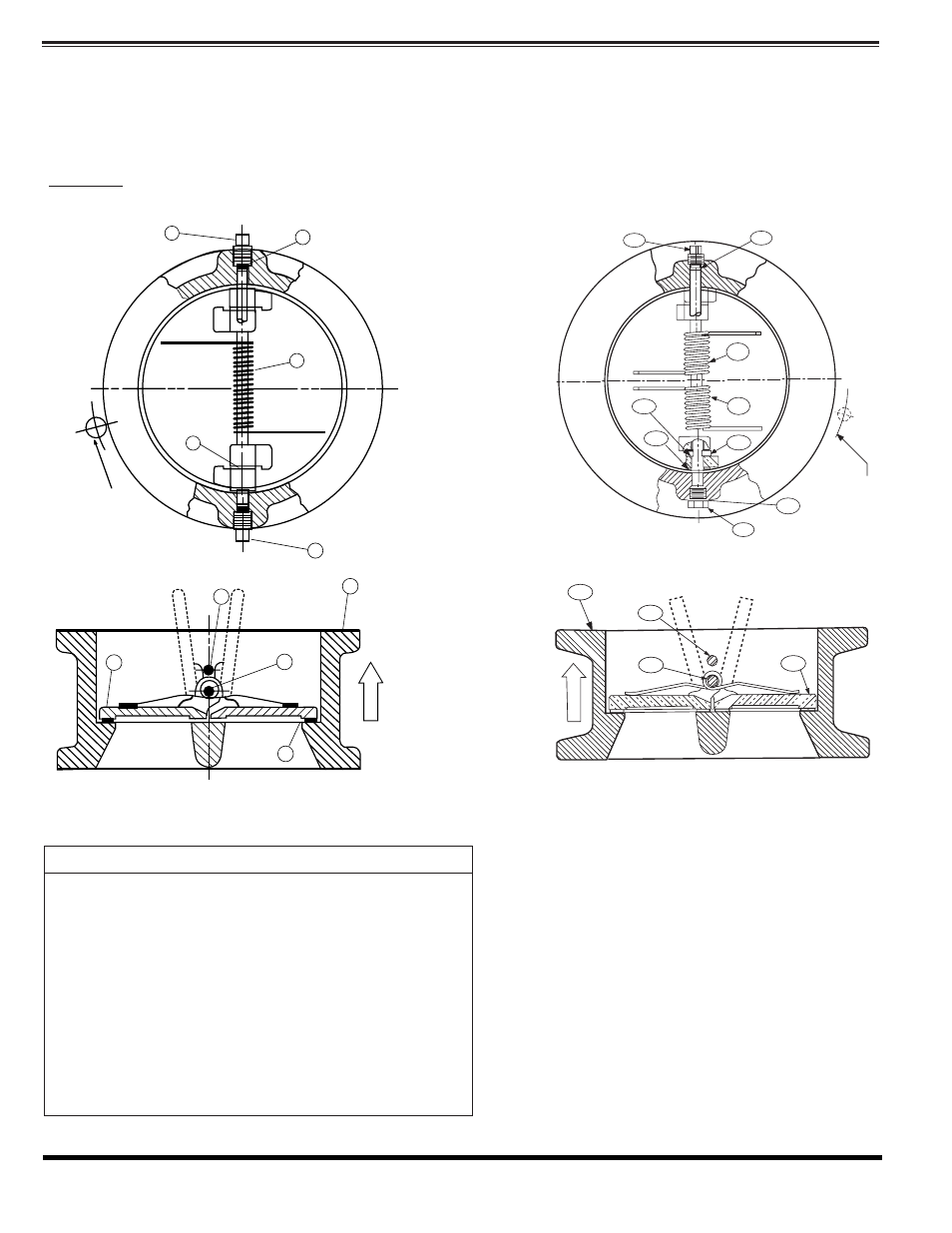

Figure 7 Two Door Check Valve

Figure 6 Two Door Check Valve

MATERIAL

1

2

3, 3A, 3B

4

4A

4B

5

6

6A

6B

7

8

9

10

Body

Cast Iron

Doors

Bronze

Spring*

(qty 2springs on 18” and larger)

Stainless Steel

Hinge Pin

Stainless Steel

Hinge Pin

Stainless Steel

Shaft collar

(item 4B on 36” and larger sizes only)

Stainless Steel

Stop Pin

Stainless Steel

Bearing* (qty. 4)

Stainless Steel

Inner Bearing*

Stainless Steel

Outer Bearing*

Stainless Steel

Hinge Pin Retainer*

Steel

Stop Pin Retainer*

Steel

Stabilizer Spheres*

Buna-N

®

O-Ring*

Buna-N

®

(18” & Larger)

*Recommended Spare Parts

PARTS AND SERVICE:

Parts and service are available from your local

representative or the factory. Make note of the

Valve Size and Model No. located on the valve

nameplate.

Contact Your Local Cla-Val

Representative or Distributor

A sales representative will quote prices for

parts or arrange for service as needed

Valve Construction (14” - 60”)

The standard check valve body general details of construction are illustrated in Figure 6, 7, 8 tables

The body (1) is either wafer style to fit between two pipe flanges or lug style for bolting two pipes flanges. The resilient seat is bonded

to the body and not adjustable or replaceable in the field.

The doors (2) and Torsion spring (3) are the only moving parts and require no maintenance or lubrication

Warning: Removal of mating flanges with out draining the pipeline may cause injury or damage to the valve

8

ANSI CLASS

125, 150,

BOLT CIRCLE

9

7

6

3