Cla-val, Dimensions – Cla-Val 501A Series User Manual

Page 2

For a more detailed IOM Manual go to www.cla-val.com or contact a Cla-Val Regional Sales Office.

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

N-501A

3. Lay valve body down with seat and hinge arm cavity facing

upwards. Use care to prevent damage.

4. Replace two bushings in valve body after using a very small

amount of waterproof grease on the inside of the bushings.

5. Install new 'O' ring seat seal in dovetail groove in valve body.

The groove is slightly larger in diameter than the 'O' ring to secure

'O' ring in place. Lubricate the 'O' ring with a very small amount of

waterproof grease before installing. Stretch 'O' ring and place or

"pop" it into groove at two opposite locations. Then push remain-

der of 'O' ring into the groove by hand pressure making sure that it

is in flat and not twisted.

6. Carefully place clapper and hinge arm assembly into body with

seating surfaces together. Line up hinge arm holes, bushings, and

hinge arm cavity of body.

7. Lubricate hinge pin with a very small amount of waterproof

grease and reinstall (using threaded rod tool) from the outside

through body, first bushing, and part of hinge arm.

8. Carefully compress torsion spring slightly and place in center of

hinge arm cavity. Insert hinge pin through spring, remaining part of

hinge arm, and second bushing. Be sure that threaded end of

hinge pin can be seen from the outside of the valve body.

9. Replace plug.

10. Check valve for freedom of movement. Place valve in a verti-

cal position with hinge pin at top. Move clapper assembly by hand

through full stroke. Larger valves should be supported to prevent

valve overturning and causing damage.

11. Conduct leak test if possible.

12. Reinstall valve in pipeline

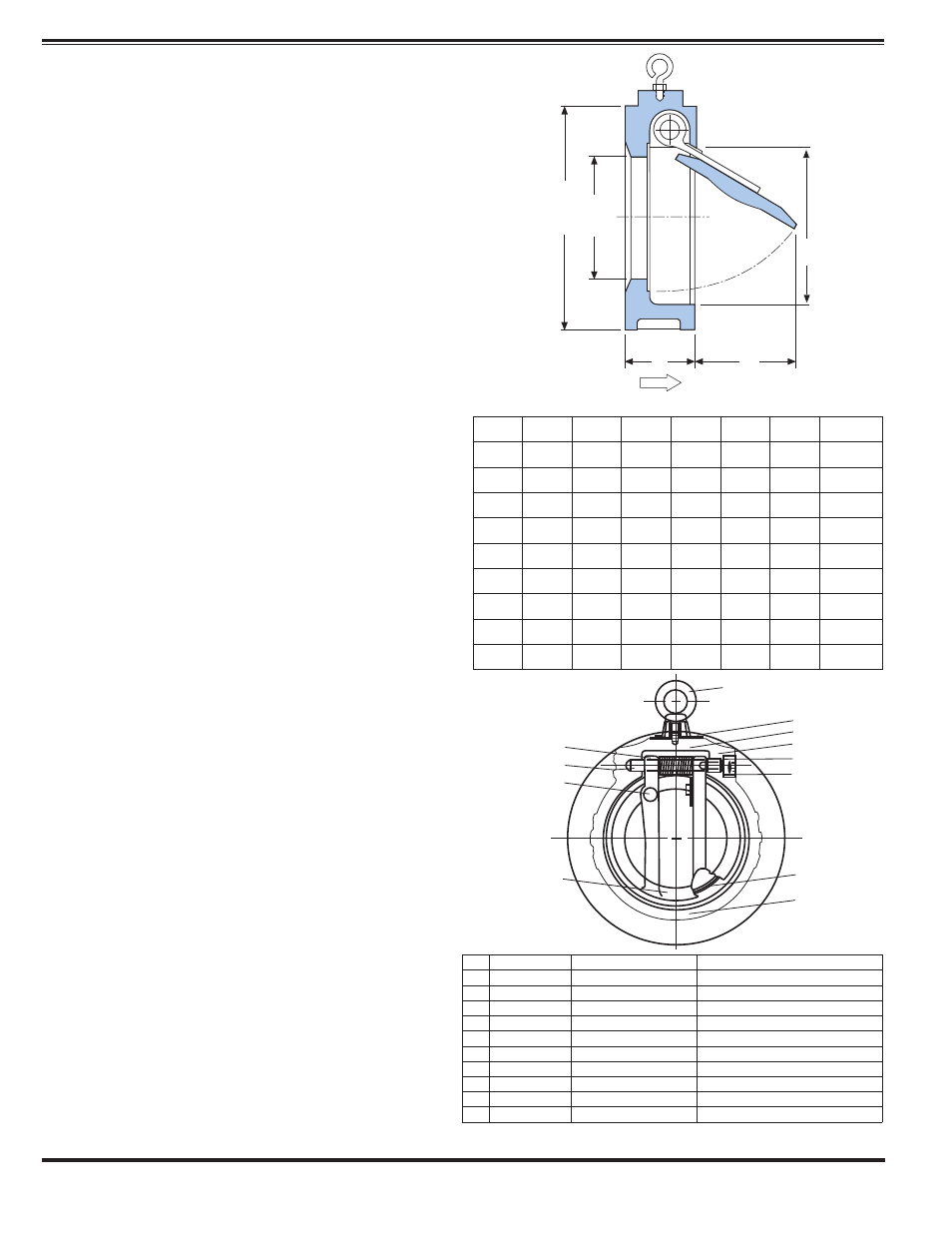

Series 501A - Wafer Swing Check Valves

(Standard) 2" - 12"

Technical Data

Pressure Rating:

235 Max psi

Temperature Range:-

5º to 210º F

Disc Cracking Pressure: All Valves equal

approximately 0.5 psi

Fluids:

Water, Wastewater, Chemicals and

Petroleum

Dimensions

(In Inches)

Size

A

B

C

D

E

(Deg.)

Q

Wt.Lbs.

2

4

1

⁄

8

1

11

⁄

16

1

3

⁄

8

13

⁄

16

59

2

3.1

2

1

⁄

2

4

7

⁄

8

1

13

⁄

16

1

3

⁄

4

1

1

⁄

16

60

2

7

⁄

8

4.2

3

5

3

⁄

8

2

1

⁄

2

2

3

⁄

8

1

1

⁄

8

62

3

6.6

4

6

3

⁄

4

2

1

⁄

2

3

1

⁄

8

1

5

⁄

8

60

4

8.1

5

7

3

⁄

4

2

3

⁄

4

3

7

⁄

8

2

1

⁄

2

61

5

12.3

6

8

3

⁄

4

3

4

1

⁄

2

3

3

⁄

4

72

6

18

8

11

3

1

⁄

2

6

1

⁄

4

4

3

⁄

4

70

7

3

⁄

4

27.3

10

13

3

⁄

8

4

1

⁄

2

7

5

⁄

8

5

3

⁄

4

66

9

3

⁄

4

51.3

12

16

1

⁄

8

4

1

⁄

2

9

1

⁄

2

7

3

⁄

8

65

11

3

⁄

4

72.6

No. Description

Material

Specifications

1

Body

Cast Iron or Steel

ASTM A48 / ASTM A216

2

Disc

316 Stainless Steel ASTM A473 / A743M- CF8M

3

Shaft

316 Stainless Steel ASTM A276

4

Plug

304 Stainless Steel ASTM A276

5

Seat (Shaft) PTFE

-

6

Seat (Body) Nitrile or Viton

TM

Commercial

7

Bushing

316 Stainless Steel ASTM A276

8

Travel Stop 316 Stainless Steel ASTM A276

9

Tag

Aluminum

-

10 Spring

304 Stainless Steel -

10

3

8

2

EyeBolt

11

9

5

7

4

6

1

B

D

C

DIA.

A

DIA.

FLOW

Q