Cla-val – Cla-Val 584 User Manual

Page 2

TROUBLESHOOTING

Several problems and solutions are presented below to assist you in

troubleshooting the valve.

• Leakage at Bottom Actuator: Remove line pressure and

exercise actuator. If leak persists, replace seals in actuator;

see the Return Flow Actuator Seal Replacement Procedure

• Leakage at Cover or Flanges: Tighten bolts, replace cover seal.

• Valve Leaks when Closed: Inspect disc for damage and

replace. Inspect body seating surface and clean if necessary.

• Valve Does not Open: Check for obstruction in valve or

pipeline. Operating pressure may be less than cracking pressure.

If less than 0.5 psig, review application with factory.

DISASSEMBLY

The valve can be disassembled without removing it from the

pipeline. Alternately, for convenience, the valve can be removed

from the line. All work on the valve should be performed by a skilled

mechanic with proper tools and a power hoist for larger valves.

Disassembly may be required to inspect the disc for wear or the

valve for deposits.

WARNING: The line must be drained before removing the cover

or pressure may be released causing bodily harm.

1 Relieve pressure and drain the pipeline.

Remove the cover bolts on the top cover.

2 Carefully pry cover loose and lift off. 12” and larger valves

have tapped holes in cover for lifting eyebolts. Avoid damage to

epoxy coating.

3 Remove disc and inspect for cracks, tears or damage in

rubber sealing surface.

4 Clean and inspect parts. Replace worn Disc or Cover Seal as

necessary and lubricate with thin film of FDA grease, such as

Lubriko #CW-606. Epoxy Coating can be cleaned with wet rag.

RE-ASSEMBLY

All parts must be cleaned. Worn, gaskets and seals should be

replaced during reassembly.

1 Lay new disc over seat with beaded seating surface directed

down and hinge at valve body top near inlet.

2 Lay cover gasket over sea,l and then place cover over bolt

holes and disc hinge.

3 Insert lubricated bolts. Be certain that long bolts are used in the

hinge area.

4 Cover bolts should be tightened in a cross over pattern to

following specifications.

5 Return valve to service by slowly repressurizing system.

TABLE 2. VALVE COVER BOLT TORQUES

TIGHTEN BOLTS IN A "STAR" OR "CROSS-OVER" PATTERN

RETURN FLOW ACTUATOR OPERATION:

WARNING: Relieve line pressure before using backflow actua-

tor or damage may occur.

An optional return flow actuator assembly is available which can be

easily installed in the field. The actuator is not designed to operate

at the valve’s maximum working pressure rating, therefore, prior to

using the actuator, close all isolation valves and bleed off line pres-

sure. To operate, turn the handle clockwise. This will open the valve

disc allowing backflow through the valve. The handle should turn

easily. When resistance is felt, the disc has reached its body stop

and is in the full open position. Upon completion of the back flushing

operation, turn the handle counter-clockwise and the valve will auto-

matically return to the closed position. Lock the actuator in the

closed position with the jam nut provided. The system is again ready

for normal operation.

RETURN FLOW ACTUATOR FIELD INSTALLATION:

WARNING: Removal of the bottom plug while under pressure

may cause bodily harm.

1 Depressurize and drain pipeline on both sides of valve.

2 Remove pipe plug in bottom boss of valve.

3 Inspect return flow rod and place in non-extended position. (The

rod should extend about 1" past end of brass bushing.) Apply

Teflon™ thread sealant to brass threads.

4 Insert threaded end of assembly into valve boss. Slowly turn

assembly into valve boss, taking care not to cross-thread

bushing. Continue turning assembly into valve for a tight fit.

RETURN FLOW ACTUATOR SEAL REPLACEMENT:

There are two parts (Rod Wiper and O-ring) on Return Flow Actuator

that are subject to wear. To replace seals, valve and pipeline must

first be depressurized and drained. Next, remove the return flow

assembly from the valve by turning brass bushing counter-clock-

wise. Disassemble Return Flow Actuator as follows:

1 Remove one vinyl caps.

2 Remove T-Handle and jam nut from rod.

3 Remove rod from bushing by screwing in rod fully clockwise

and pull rod through valve end of bushing.

4 Lubricate two new seals with FDA approved grease such as

Lubriko #CW-606 and install in bushing end grooves. Note part

location on Fig. 3.

5 Clean, lubricate, and reinstall rod in bushing.

6 Re-install jam nut and T-Handle.

7 Place vinyl cap on handle.

8 Apply Teflon™ thread sealant to bushing and carefully thread

into valve taking care not to cross-thread bushing.

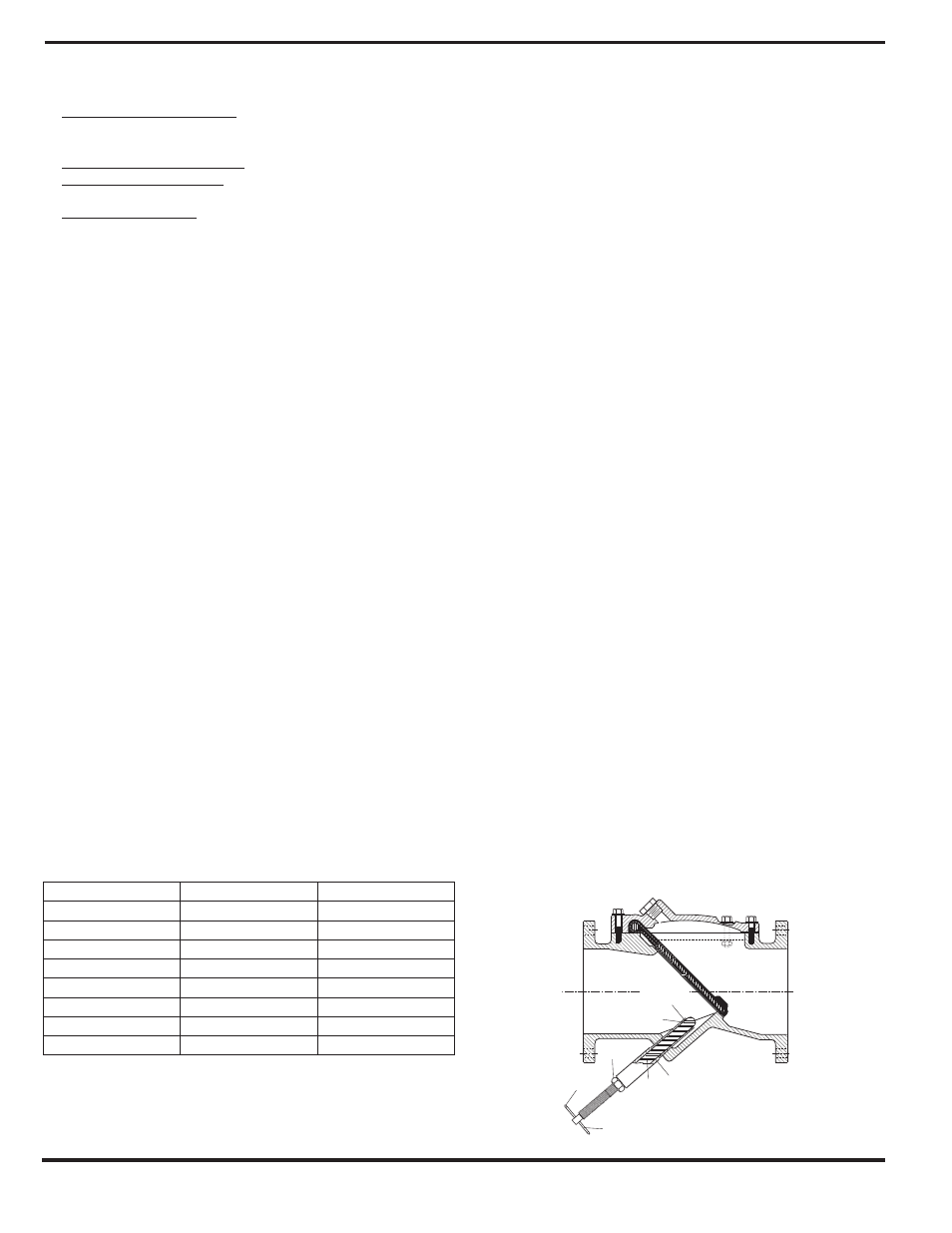

FIG. 3. BACKFLOW ACTUATOR ASSEMBLY

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

N-584 Flex Check Valve

Valve Size (inches)

Cover Bolt Size

Torque (ft-lbs.)

2 - 2.5

1/2

75

3"

7/16

50

4

1/2

75

6

7/16

50

8

9/16

100

10

3/8

200

12 - 20

7/8

250

24

1

300

Cap

(Vinyl)

Bushing

(Brass)

Rod Wiper*

(Molythane)

O-Ring*

(Buna-n®)

Handle

(Stainless Steel)

Rod

(Stainless Steel)

Jam Nut

(Brass)