Silent check valves – Cla-Val 581 Series Technical Manual User Manual

Page 4

SILENT CHECK VALVES

580 & 581

SERIES

INSTALLATION / OPERATION / MAINTENANCE

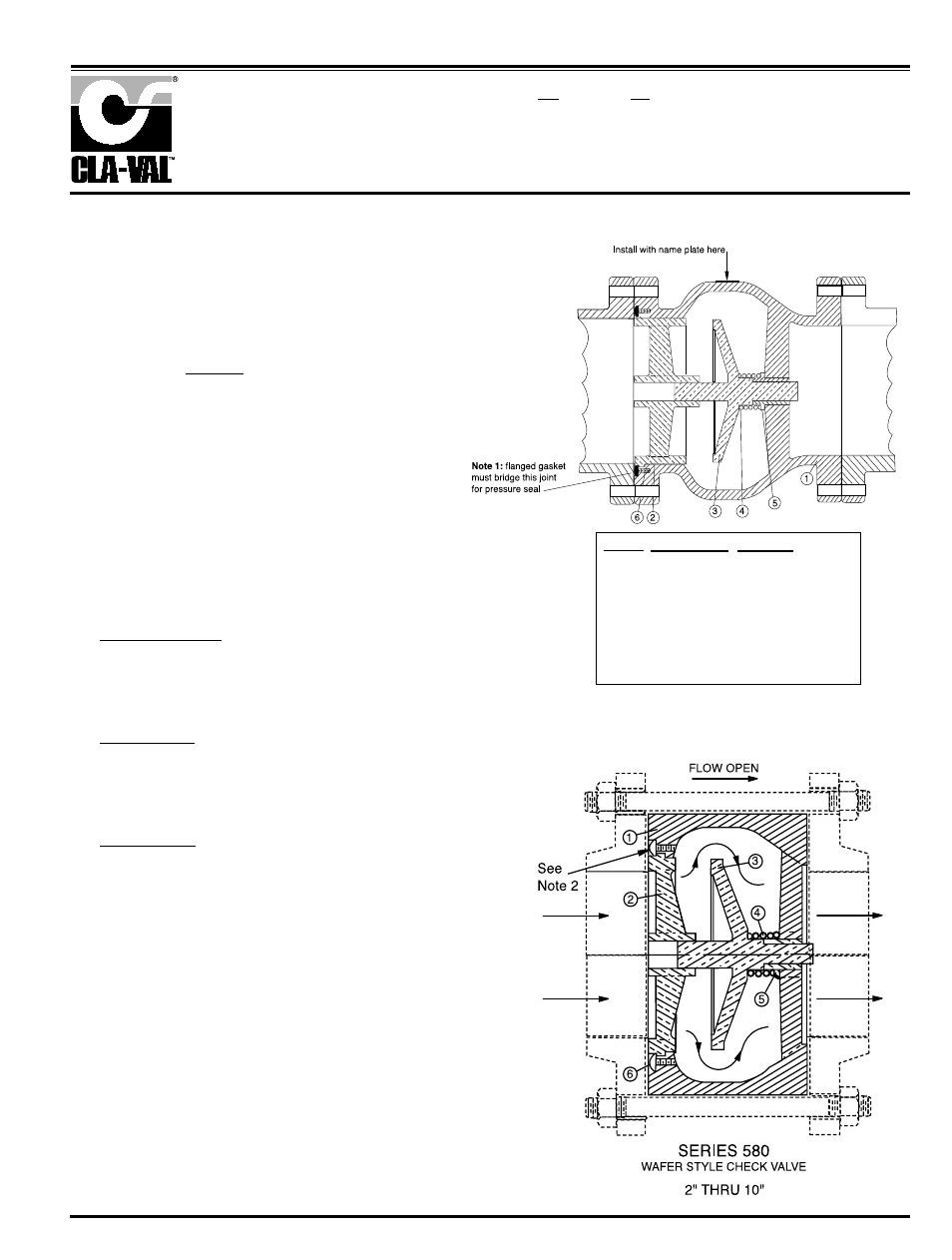

OPERATION:

Cla-Val Silent Check Valves operate automatically, to

open... when pump flow starts and close silently ...when

pump flow stops.

INSTALLATION:

Silent Check Valves, Wafer and Globe style must be

installed between flat faced iron or steel flanges per ANSI

B16.5 or Awwa 207, utilizing a full faced gasket to bridge

the joint between the seat O.D. (2) and the body (1) flange

face. In this manner a pressure seal at this joint is made

(see Note 1). Install the valve so that the nameplate data is

plainly read and the flow arrow points in the flow direction.

Detail

1

2

3

4

5

6

Description

Body

Seat*

Disc*

Spring*

Bushing*

Screw*

Material

Cast Iron

Bronze or SS

Bronze or SS

(Optional Buna-N

®

)

Stainless Steel

Bronze

Stainless Steel

(3” & larger valves)

* Recommended Spare Part Kit

Note 2: All size 2” and 2 1/2” valves have

threaded seats in liev of screws

Series 581

Globe Style

Check Valve

2” thru 42”

MAINTENANCE:

Cla-Val Silent Check Valves are ruggedly designed for years

of trouble-free service. Therefore, regular maintenance is

not required. However, during initial start-up period the following

problems may surface (due to mis-application) that can be

easily resolved:

A. No Flow thru Valve:

1. Observe that the flow arrow name plate, on the

valve body, is pointing in the direction of flow.

2. Check that the down stream shut-off valve is full open.

B. Valve Chatters:

1. Confirm that the flow velocity is a minimum 3’/Sec.

2. Check that there is a minimum of 3 diameters of

straight pipe installed up stream of the silent check valve.

C. Valve Leakage:

1. Confirm a full face gasket is installed per Note 1.