316ss hytrol valve – Cla-Val 590-01/6590-01 Technical Manual User Manual

Page 5

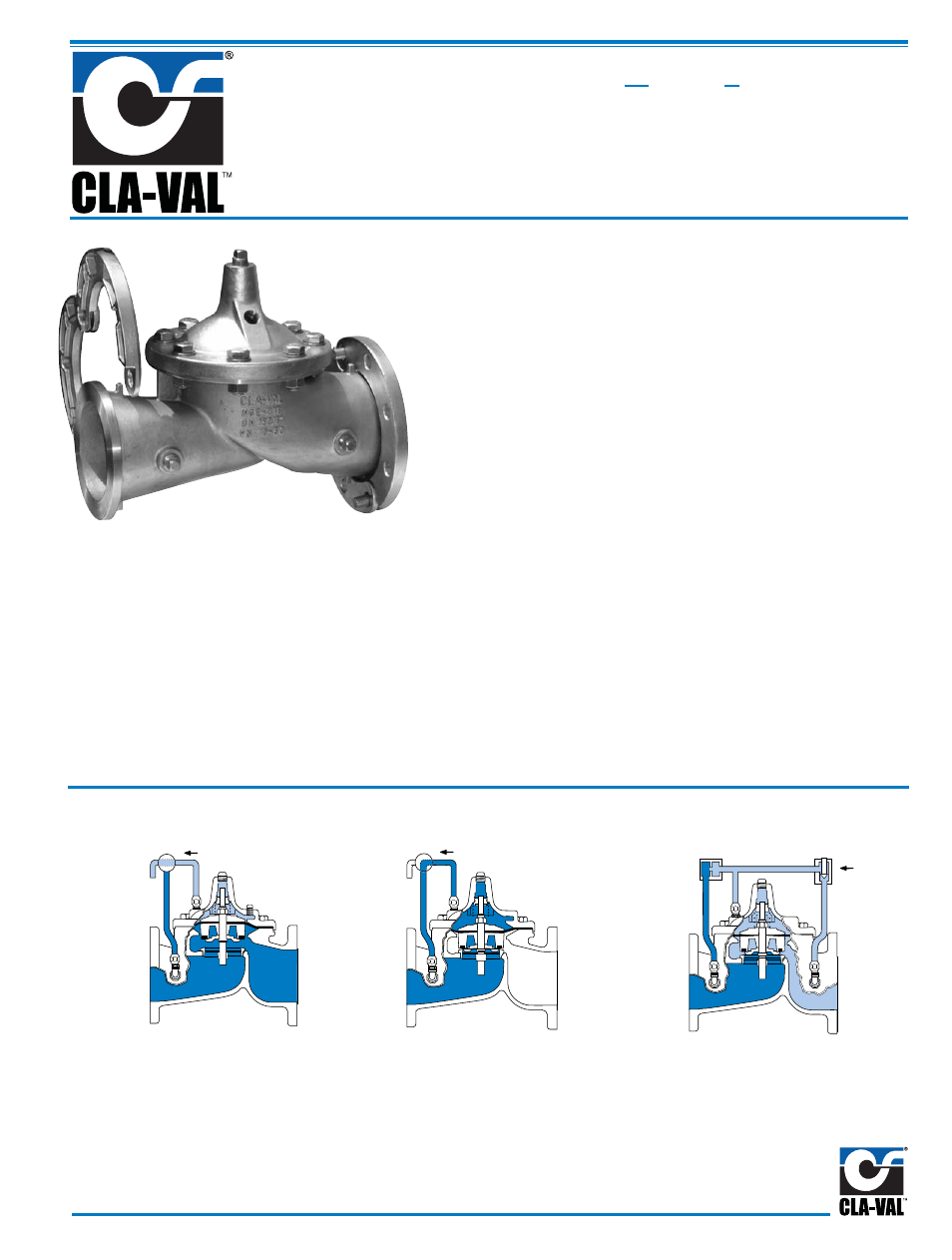

316SS Hytrol Valve

100-44

MODEL

•

All 316 Stainless Steel

•

Reduced Cavitation Design

•

Drip-Tight, Positive Sealing Action

•

Service Without Removal From Line

•

Every Valve Factory Tested

•

Three-Year Warranty

The Cla-Val Model 100-44 Hytrol 316SS Valve is a hydraulically operated,

diaphragm actuated, globe pattern valve with all 316 Stainless Steel metal

parts. Specially designed 316 Stainless Steel removable slip-on flanges

provide 150 or 300 ANSI class flange connections that meet ANSI and ISO

standards. This valve is ideal for control valve applications where fluid

compatibility is often a problem. The standard Electropolish finish on the

316 Stainless Steel parts offers extreme corrosion resistance to many

industrial fluids such as seawater, high alkyl or high acid concentrations

or other aggressive or corrosive fluids.

The Model 100-44 Hytrol consists of these major components: body,

flanges, diaphragm assembly and cover. The diaphragm assembly is the

only moving part and is guided top and bottom by a precision-machined

stem. A non-wicking diaphragm of nylon fabric reinforced, synthetic rubber

creates the control chamber for the valve. A resilient, synthetic rubber disc

forms a drip-tight seal, with the renewable seat, when pressure is applied

to the control chamber. The rugged simplicity of design and packless con-

struction assures a long life of dependable, trouble-free operation. Smooth

flow passages and fully guided diaphragm assembly assure optimum con-

trol, when used in piping systems requiring remote control, pressure regula-

tion, solenoid operation, rate of flow control or check valve operation.

Principle of Operation

Full Open Operation

When pressure in the cover cham-

ber is relieved to a zone of lower

pressure, the line pressure at the

valve inlet opens the valve, allow-

ing full flow.

Modulating Action

The valve holds any intermediate

position when operating pressure

is equal above and below the

diaphragm. Using a Cla-Val

“Modulating” Control will

allow the valve to automati-

cally compensate for line

pressure changes.

Tight Closing Operation

When pressure from the valve inlet

is applied to the cover chamber, the

valve closes drip-tight.

On-Off Control

On-Off Control

Modulating

Control

(Reduced Internal Port)