Cla-val, Hytrol main valve, X140-1 security cap option – Cla-Val 93-01/693-01 Quick Manual User Manual

Page 2

CLA-VAL

Copyright Cla-Val 2008 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

N-93-01/693-01 (R-9/08)

H

3

5

2

D1

Y

B

S

C

4

B

A

1

D2

B

D3

INLET

OUTLET

SOLENOID DRAIN

TO ATMOSPHERE

CS3

3

1

2

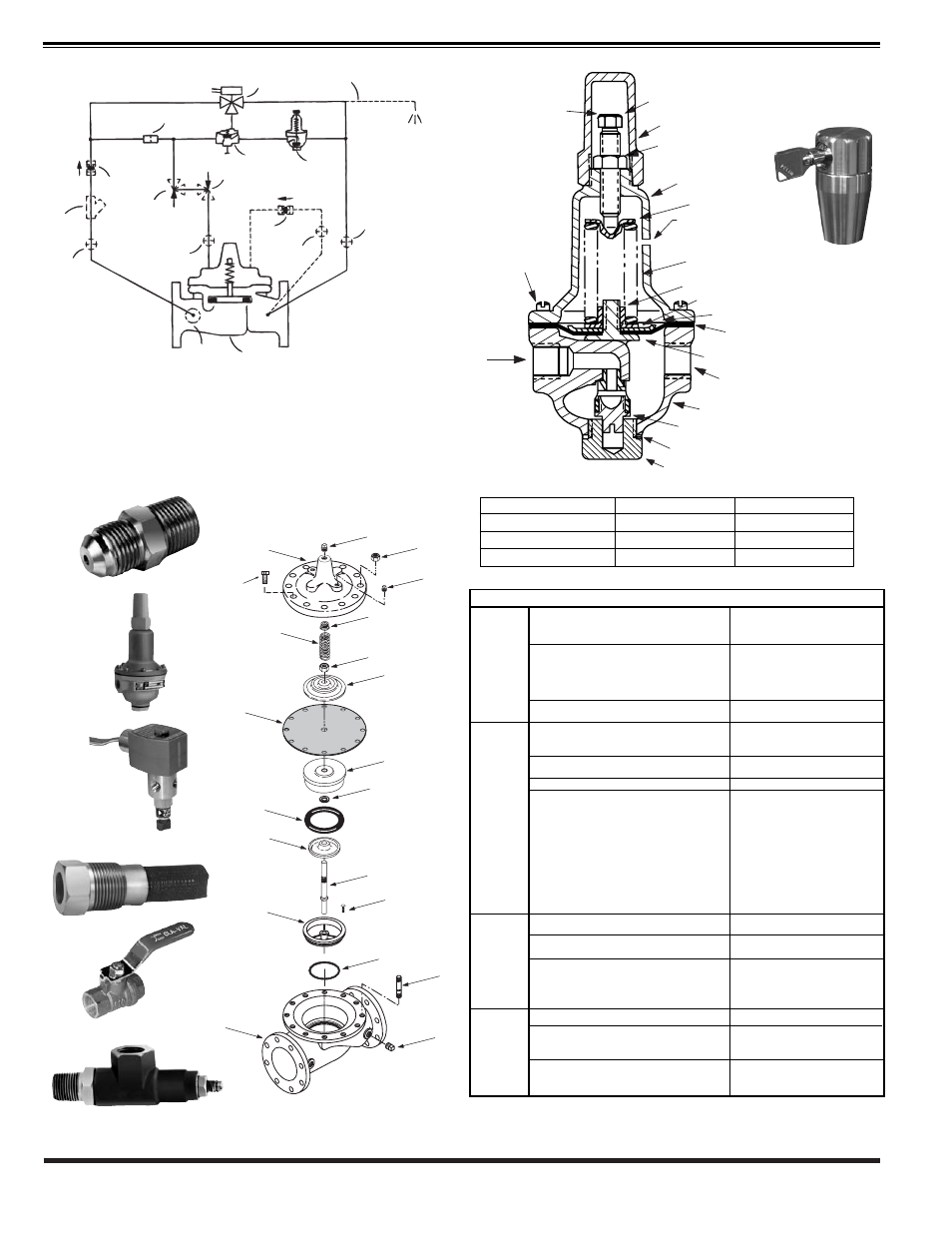

BASIC COMPONENTS

1 100-01 Hytrol (Main Valve)

100-20 600 Series Hytrol (Main Valve)

2 X58C Restriction Tube Fitting

3 CRD Pressure Reducing Control

4 100-01 Hytrol - Rev. Flow

5 CS3 Solenoid Control

OPTIONAL FEATURES

A X46A Flow Clean Strainer

B CK2 (Isolation Valves)

C CV Flow Control - Closing

D Check Valves with Isolation Valve

H Solenoid Drain to Atmosphere

S Opening Speed Control

Y X43 “Y” Strainer

For a more detailed IOM Manual go to www.cla-val.com or contact a Cla-Val Regional Sales Office.

CRD

93-01/693-01 SCHEMATIC

COVER

PIPE PLUG

COVER BEARING

SPRING

STEM NUT

DIAPHRAGM WASHER

DISC RETAINER

BODY

*

SPACER WASHERS

DISC GUIDE

SEAT

PIPE PLUG

STEM

SEAT O-RING

STUD

8" and Larger

*

DIAPHRAGM

*

DISC

*

Repair Parts

Seat Screw

8" and Larger

(Globe

or

Angle)

PIPE PLUG

HEX NUT

8" and Larger

Cover Bolt

6" and Smaller

CRD

X58C

CS3

X46A

CK2

CV

HYTROL MAIN VALVE

inlet

Cover vent

(3/8" NPT)

Cap

Adjusting Screw

Jam Nut

Cover

Spring

Hex Nut

Belleville Washer

Diaphragm Washer

Diaphragm*

Yoke

Body and Seat Assy

Disc Retainer Assy

Gasket*

Plug, Body

*Machine Screw

(Fil.Hd) 8 Req'd

Spring Guide

Pressure Setting

Adjusting Screw

(Turn Clockwise to

Increase Setting)

2.

3.

1.

3.

5.

A.

B.

C.

SYMPTOM

PROBABLE CAUSE

REMEDY

Main Valve

Fails to

Open

Main Valve

Fails to

Close

Fails to

Regulate

Solenoid

Valve

will not

Operate

No pressure at valve inlet

Main valve diaphragm assembly inoperative

Pressure Reducing Control (CRD) not opening:

1. No spring compression

2. Damaged spring

3. Spring guide not in place

4. Yoke dragging on inlet nozzle

Flow Control (CV) disc inoperative,

corrosion or excessive scale buildup on stem

Foreign matter between disc and seat or worn

disc. Scale on stem

Diaphragm damaged

X46 Flow Clean Strainer plugged, or

X43 “Y” Strainer plugged

CK2 (isolation valves) closed

Pressure Reducing Control (CRD)

remains open:

1. High spring compression

2. Damaged spring

3. Spring guide not in place

4. Yoke dragging on inlet nozzle

5. Diaphragm damaged or loose diaphragm

nut. Leakage from vent hole in cover

6. Worn or damaged disc retainer assembly

Air in main valve cover and/or tubing

Pressure Reducing Control (CRD)

yoke dragging on inlet nozzle

Pressure Reducing Control (CRD) spring

not in correct range to control

Solenoid voltage

Burned out solenoid coil

Check inlet pressure Disassemble,

clean and polish stem, disc guide,

replace defective parts

1. Tighten adjusting screw

2. Disassemble and replace

3. Assemble properly

4. Assemble properly

Disassemble, clean and polish stem,

Replace worn parts

Disassemble main valve

remove foreign matter, clean or

replace damaged parts

Remove and clean or replace

units

Open isolation valves

1. Back off adjusting screw

2. Disassemble and remove

obstruction

3. Disassemble and replace

4. Assemble properly

5. Disassemble, replace diaphragm

and/or tighten nut

6. Remove and replace

Loosen top cover plug and/or

tubing fining and bleed air

Assemble properly

Check outlet pressure require-

ments and compare existing spring

with chart

Check voltage across coil leads

must be minimum of 85% of

nameplate rating

Check for open circuit coil

Replace coil

SOLENOID SYMPTOMS

CRD adjust range (psi)

Spring Color

psi change per turn*

2 - 30

Stainless Steel

3

15 - 75

Red

9

30 - 300

* approximate. Use gauge at valve outlet to set

Green

27

X140-1

Security Cap

Option