Pump Solutions Group Neptune Series 600 dia-PUMP MODELS 610 thru 647 User Manual

Page 8

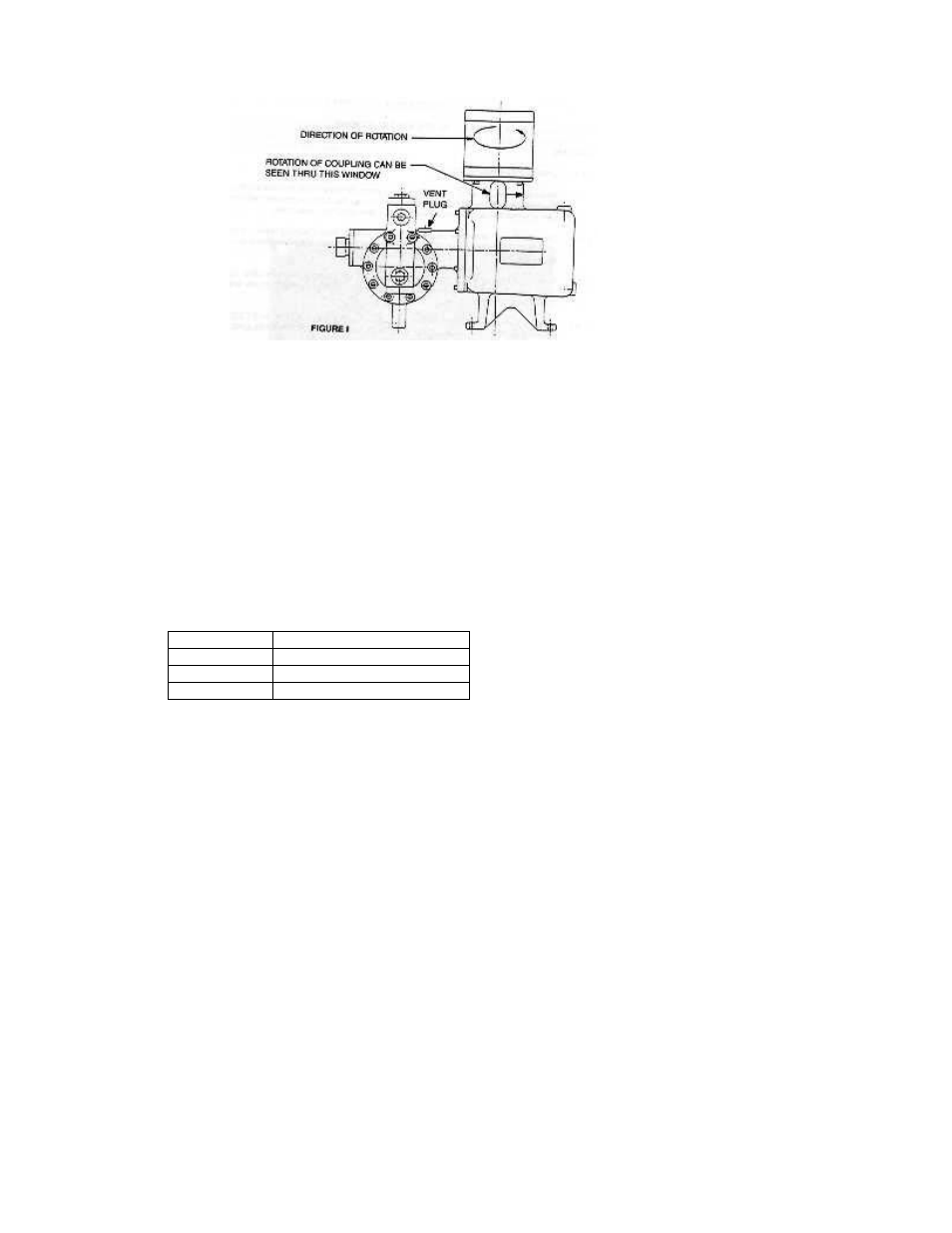

Please note Figure 1, indicating the correct rotation. Operation with the incorrect rotation will damage the pump and motor.

1.0.8

Please note, that some items in the parts list have more than one part number for an individual figure number.

These different part numbers insure unique identification of parts, which are available in more than one material of

construction, or as in the case of gears, more than one speed. Please use the part number, not the figure number

when ordering.

1.0.9

Fill gear box and pump by pouring the hydraulic fluid (drive lubricant) supplied through the fill opening at the rear

of the pump. Pour fluid in slowly until it is at the dipstick mark. The control knob should be in the zero position

during the filling. PLEASE NOTE: TO VENT THE AIR, REMOVE A VENT PLUG, LOCATED ON TO OF

THE OIL HEAD.

Allow 30 minutes for hydraulic fluid to make its way into pump chamber and then recheck fluid level.

The hydraulic fluid supplied by Neptune is EP SAE 90.

Common sources for hydraulic fluid are:

Shell Oil

Omala #220

Mobil Oil

Mobil Gear #629

Sun Oil

Sun Oil #220

Texaco

Meropa #220

2.0

SUCTION PIPING

2.0.1

The suction piping to the pump must be absolutely air tight and one size larger than suction inlet size of the pump.

It is suggested that the suction piping be tested with low pressure and a soap solution to assure that no leaks exist.

Limit the total length of the suction line to 3-4 feet suction lift or 6-7 feet flooded suction. Minimize bends,

elbows, or other restrictions.

2.0.2

NEPTUNE RECOMMENDS THAT THE “dia-PUMPS” BE OPERATED WITH A FLOODED SUCTION, AS

THIS WILL FACILITATE START UP AND INCREASE THE SERVICE LIFE OF THE PUMP.

2.0.3

It is highly recommended that all solution tanks be furnished with a low level cut off switch or low level alarm

and cut off switch to prevent the pump from running dry. OPERATION AGAINST A DRY SYSTEM WILL

CAUSE DAMAGE TO THE PUMP DIAPHRAGM AND REDUCE THE OPERATING LIFE OF THE PUMP.

5