Water piping system, Gas input rate, Piping installation – John Wood Polaris Commercial High-Efficiency User Manual

Page 13: Corrosion and water quality

13

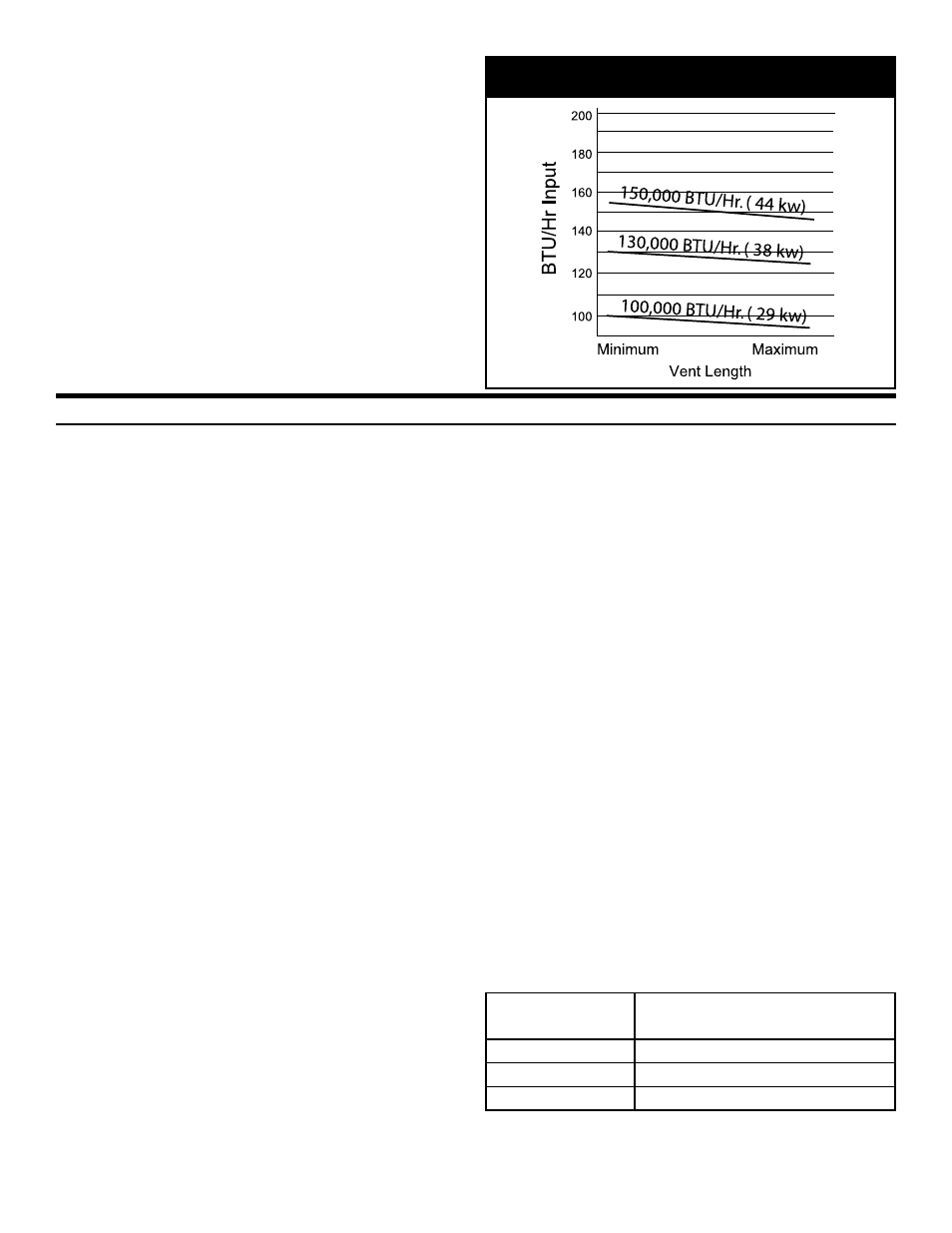

Figure 14: Input Graph

Gas Input Rate

The gas input rate of this water heater is affected by

several environmental factors such as:

•

The heating value of the gas

•

The air and gas densities (which vary widely due to baro-

metric pressure and temperature changes)

•

Venting installations (pipe diameter, length and fittings)

•

Altitude

When measuring the input rate these factors should be

incorporated into the calculations. Also measure the gas

consumption over a sufficiently long time to obtain an

accurate gas consumption rate (e.g. 3-5 minutes, not one

revolution of the meter needle).

Long vents and each additional elbow, inherently reduce

the gas input rate due to increased resistance to moving

combustion air and flue gases. The approximate maximum/

minimum input for the 100k, 130k, and 150k models is

shown in figure 14.

WATER PIPING SYSTEM

Piping Installation

Piping, fittings, and valves should be installed according to

the installation drawing (figure 15). If the indoor installation

area is subject to freezing temperatures, the water piping

must be protected by insulation.

The water supply pressure should not exceed 80 psi

(551.5 kPa). If this occurs, a pressure reducing valve with a

bypass should be installed in the cold water inlet line. This

should be placed on the supply to the entire house in order

to maintain equal hot and cold water pressures.

Important: Heat cannot be applied to the water fittings

on the heater as they may contain nonmetallic parts.

If solder connections are used, solder the pipe to the

adapter before attaching the adapter to the hot and

cold water fittings.

Important: Do not install this water heater with iron or

galvanized piping. Use brass caps on all unused inlet/

outlet connections.

1. Install the water piping and fittings as shown in figure

15. Note: If state or local codes require, install a vacu-

um relief valve per the manufactures instructions in the

cold water supply line. Connect the cold water supply

(use 1” NPT) to the fitting marked “COLD INLET”.

Do not turn the cold water nipple. The mark should

remain along the top side of the nipple. Connect the

hot water supply (use 1” NPT) to the fitting marked

“HOT OUTLET”.

2. Always use a suitable grade of joint compound and be

certain that all fittings are tightened properly.

3. The installation of unions in both the hot and cold water

supply lines is recommended for ease of removing the

water heater for service or replacement.

4. If installing the water heater in a closed water system,

install an expansion tank in the cold water line as speci-

fied under “Closed System/Thermal Expansion” (Page

14).

5. Install a shut-off valve in the cold water inlet line. It

should be located close to the water heater and be

easily accessible. Know the location of this valve and

how to shut off the water to the heater.

6. The

Polaris

®

gas water heater is shipped with a factory-

installed Temperature and Pressure Relief Valve.

Install a discharge line in the opening in the T & P valve

(see instructions on Page 16).

7. After piping has been properly connected to the water

heater, remove the aerator at the nearest hot water

faucet. Open the hot water faucet and allow the tank

to completely fill with water. (To prevent damage to

the unit, DO NOT connect power until the tank is

COMPLETELY FILLED). To purge the lines of any

excess air, keep the hot water faucet open for 3 min-

utes after a constant flow of water is obtained. Close

the faucet and check all connections for leaks.

Corrosion and Water Quality

Water quality will vary from location to location and may

contain contaminates that may reduce the life or perfor-

mance of the water heater. To test for contaminates a

water quality test kit is available, reference part number

6903791.

Contaminates which can reduce the life or performance

of the water heater if present in high quantities include

those which contribute to hardness (dissolved minerals

such as sodium, calcium and magnesium); plus chlorides

and sulfates. Additionally, water that is too acidic or basic

(measured as pH) can reduce the life of the water heater.

Water treatment systems (such as water softeners for

hardness) should be used and maintained properly if the

contaminate levels exceed the following:

Warranty is void in applications which exceed the

water quality requirements listed below.

Table 2:

Total Hardness:

12 grains per gal. (205 mg/liter) max.

Chloride:

200 mg/liter max.

pH:

6.5-8.0

Alkalinity:

200 mg/liter max.