Model lr, lmr, lrz, lmz, 4 bearings, 5 condensation – Xylem LMZ User Manual

Page 47: 6 approximate value for sound pressure level

Installation, Operating and Maintenance Instruction

Model LR, LMR, LRZ, LMZ

page 43

3.3.2 General informations

The reuse of mech. seals that have already

been used for a longer time can lead to leaking

at the seal faces after reinstallation. Therefore

the replacement of the mech. seal with a new

one is recommended. The removed mechanical

seal can be reconditioned by the manufacturer

and serve as a replacement mech. seal.

3.3.3 Informations for the mounting

Pay attention to the utmost cleanness!

Especially the seal faces must be clean, dry and

undamaged. Don’t apply lubrication on the seal

faces of the mech. seal.

If a lubricant is provided with the replacement

mech. seal, you should use this.

Use mineral grease or oil only if you are

completely sure that the elastomers of the

mech. seal are oil resistant. Use no silicone.

Use only lubricants with which you are certain

that no dangerous reaction can occur between

the lubricant and the pumped medium.

Have all required parts prepared so that

assembly can be completed quickly. The

lubricants are only effective for a short time.

After that, the axial mobility and thus the

automatic adjustment of the elastomers is lost.

Never push elastomers over sharp edges. If

necessary, use mounting devices.

During installation, push the mech. seals with a

bellows in such a way that the bellows is

compressed and not stretched (danger of

tearing apart!).

3.4 Bearings

The motor bearings also serve as pump bearings. The

bearings are greased for life and are thus

maintenance-free.

3.5 Condensation

For motors which are used at high temperature

differences and places with extreme climatic situations

with high humidity, we recommend to use a motor with

anti-condensation heater to prevent the unit of

condensation water inside the housing. During motor

run the anti-condensation heater must not be switched

on.

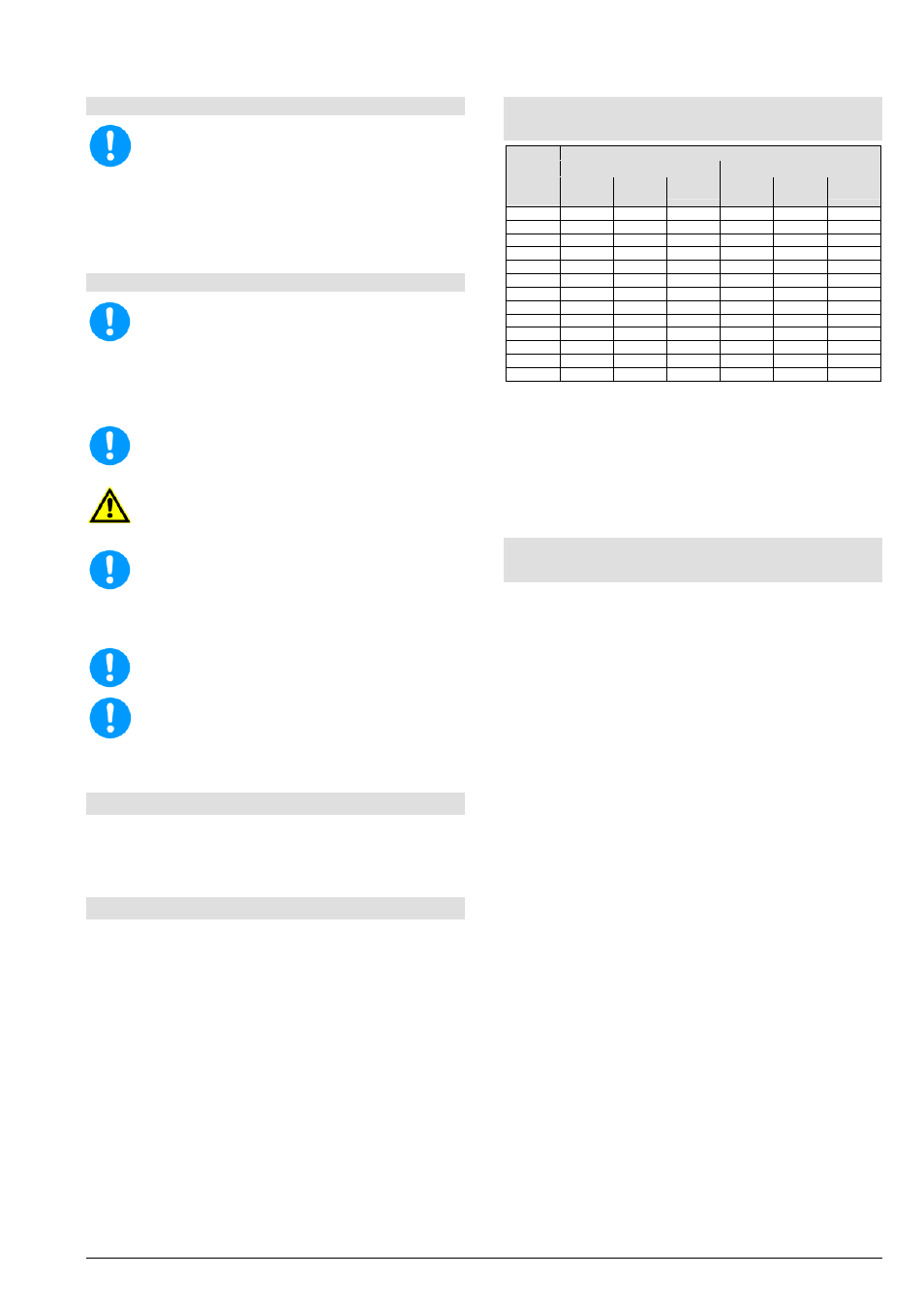

3.6 Approximate Value for Sound

Pressure Level

Nominal

power

P

N

in kW

Sound pressure level L

pA

in dB(A)

Pump alone

Pump + Motor

2950

min

-1

1450

min

-1

2950

min

-1

1450

min

-1

0,55 50,5 49,5

58,0 52,0

0,75 52,0 51,0

59,0 54,0

1,1

54,0

53,0 60,0

55,5

1,5

55,5

55,0 63,5

57,0

2,2

58,0

57,0 64,5

59,0

3,0

59,5

58,5 68,5

61,0

4,0

61,0

60,0 69,0

63,0

5,5

63,0

62,0 70,0

65,0

7,5

64,5

63,5 70,5

67,0

11,0 66,5 65,5

72,0 69,0

15,0 68,0 67,0

72,5 70,0

18,5 69,0 68,5

73,0 70,5

22,0

70,5

74,5

Sound pressure level L

pA

measured in 1 m distance

from pump surface acc. to DIN 45635, part 1 and 24.

Room and foundation influences are not considered.

The tolerance for these values is

3 dB(A).

Addition with 60 Hz-operation:

Pump alone:

Pump with motor: +4 dB(A)

3.7 Permitted Nozzle Loads and Torques

at the Pump Nozzles ...

... following the Europump-Recommendation for

pump acc. to ISO 5199.

The data for forces and torques are only valid for static

piping loads and are valid for one nozzle. All values for

forces and torques refer to standard materials 0.6020

(Type LR) and/or 0.6025 (Type LMR, LMZ).