Description, Transport, handling, storage, 1 models – Xylem Z8 ZR8 Z10 ZR10 Z12 ZR12 User Manual

Page 29: 2 pipe connection, 3 bearings, 4 motor, 1 transport, handling

Installation, Operating and Maintenance Instruction

page

29

Installation position

Vertical and horizontal installation is allowed. The

maximum operating flow must be kept. The pump

design is with or without integrated non-return valve

(at vertical or horizontal installation).

Protection against running dry

The pumps must not run dry under any circumstances

(not even for a short time for the purpose of checking

the direction of rotation), since overheating can

damage pump components. Therefore we

recommend monitoring the required minimum water

level in order to protect the pump.

Pump Backflow

It is not permissible to drain the pressure line after the

pump has been switched off as the backflow speed

can be many times the operating speed and would

destroy the unit. A backflow through the pump can be

prevented by suitable non-reflux fittings as close to the

pump as possible insofar as a non-return valve are not

installed in the pump.

2. Description

2.1 Models

Z8*/ZR8*

Z10*/ZR10*

Z12*/ZR12*

Submersible pump for wells with 8"-

12” bore.

Please see the Appendices for the sectional drawings

and index of parts for each pump.

The detailed designation of the pump is shown on the

pump nameplate ort he order confirmation.

2.2 Pipe Connection

pipe connection

internal thread

Z8*/ZR8*

Rp5 ÖNORM EN 10226

Z10*/ZR10*

Rp6 ÖNORM EN 10226

Z12*/ZR12*

API 8" NPT

Other pipe connections are executed optionally on

customer request and are seen in the order

confirmation.

2.3 Bearings

The pump shaft is maintained multiple in

maintenance-free plain bearings.

2.4 Motor

The motor of your pump has its own Operating

Instructions. It is vital that you read and comply

with the instructions and safety instructions

contained in them.

3. Transport, Handling, Storage

3.1 Transport, Handling

Check the pump/pump unit immediately upon

delivery/receipt of despatch for damage or missing

parts.

The pump/pump unit must be transported carefully

and by competent personnel. Avoid serious

impacts.

Keep the pump/pump unit in the same position in

which it was supplied from the factory. Take note

of the instructions on the packaging.

The intake and discharge side of the pump must

be closed with plugs during transport and storage.

Dispose of all packing materials in accordance

with local regulations.

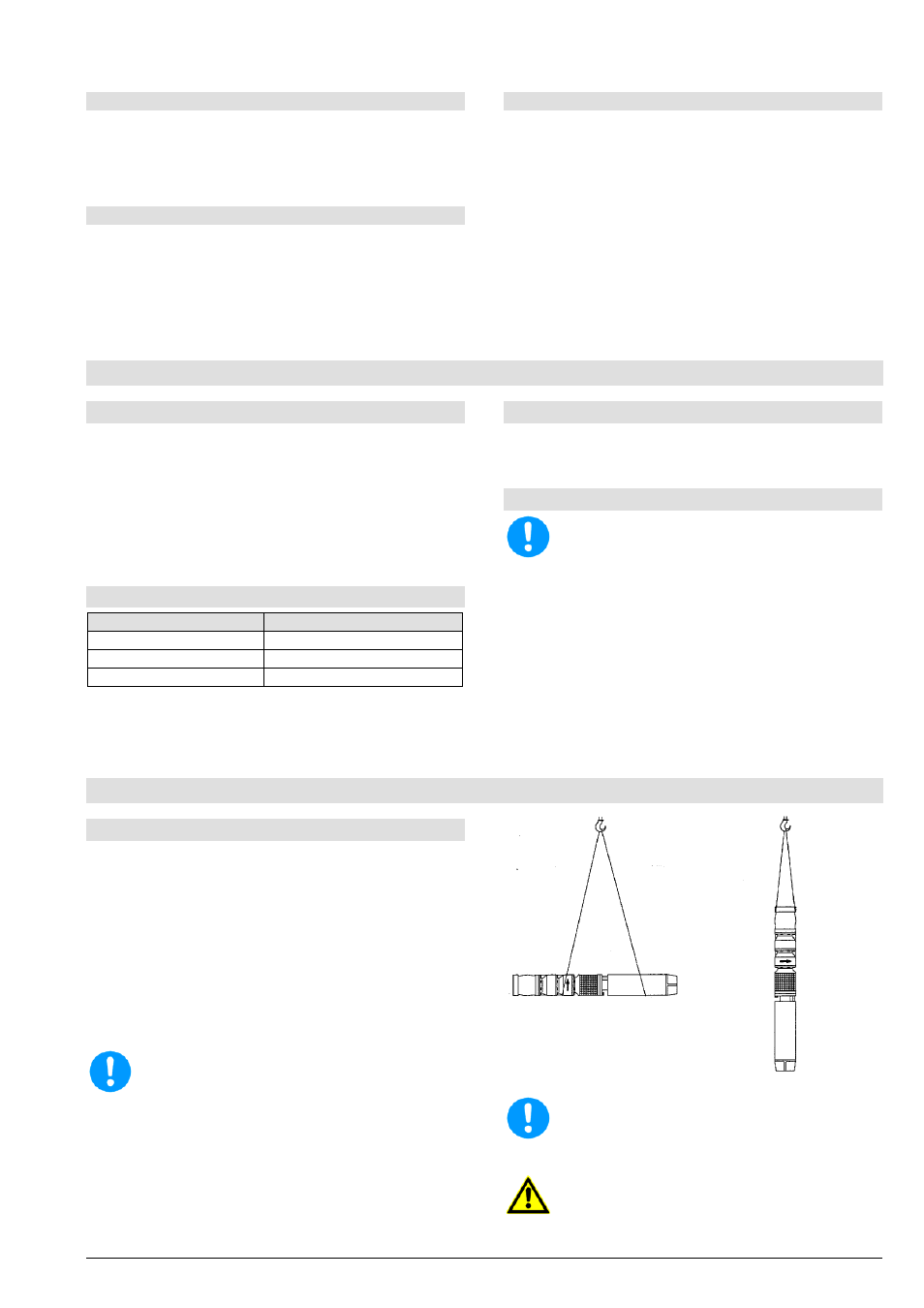

Lifting aids (stacker, crane, crane mounting

device, lifting blocks, sling ropes, etc.) must have

the proper dimensions so that they can bear the

weight of the pump, motor and the pressure line

when it is full of water.

The pump/pump unit may only be lifted by solid

points. The following illustration shows the correct

method of carrying by crane.

Under no circumstances may the unit be lifted

on to the motor cable. Do not damage the cable

during transport (do not squeeze, bend or drag).

The cable ends must be kept dry.

Do not stand underneath suspended loads; take

note of the general regulations on prevention of

accidents.