6 settings priority, 4 external analog input 4-20ma, 5 external temperature sensor – Xylem ECOCIRC XL, XLplus Electronic drive User Manual

Page 6: 6 communication bus (standard), 7 communication bus (optional), 8 optional wireless / rs485 module

2.5.4 External analog input 4-20mA []

The circulator can be equipped with a 4-20mA external

differential pressure sensor, connected to terminals

and

, with the purpose of increasing the precision in

operating modes involved with pressure regulation.

For setting, in the drive, the correct pressure sensor

model used, see par. 4.3.5.3.

2.5.5 External temperature sensor []

The circulator can be equipped with an external KTY83

temperature probe (1K

Ω at 25

C), connected to

terminals

and

, with the purpose of measuring an

absolute or a differential water temperature, in

temperature dependent / influenced operating modes.

For setting, in the drive, the desired temperature-

dependent control mode, see par. 6.1.2

2.5.6 Communication bus (standard)

[]

The circulator (model ecocirc XLplus only) can

communicate remotely through a built-in RS485 port,

whose characteristics are:

Interface

RS485 (TIA/EIA) optically isolated

Baud rate

4800 / 9600 (factory setting) / 14400 /

19200 / 38400 / 56000 / 57600 baud

Data

format

8 data bits, no parity, 1 stop bit

Protocol

Modbus RTU (factory setting)

Bacnet MSTP

5

Address

1

247 Modbus RTU

0

127 Bacnet MSTP

5

ID #1 factory setting

For setting, in the drive, the correct communication

parameters, see par. 4.3.5.2.

NOTICE

This communication bus, implemented on terminals

,

and

, is the only one which can be used for

connecting 2 pumps in dual pump operations (see par.

4.3.5.1)

2.5.7 Communication bus (optional)

[]

The circulator (model ecocirc XLplus only) can

communicate remotely through an optional RS485

port, available exclusively in case the optional Wireless

module or the optional RS485 module is installed;

main characteristics of this port are:

Interface

RS485 (TIA/EIA) not isolated

Baud rate

4800 / 9600 (factory setting) / 14400 /

19200 / 38400 / 56000 / 57600 baud

Data

format

8 data bits, no parity, 1 stop bit

Protocol

Modbus RTU (factory setting)

Bacnet MSTP

5

Only on ecocirc XLplus terminal-connected models

Address

1

247 Modbus RTU

0

127 Bacnet MSTP

5

ID #1 factory setting

The aim of this additional communication bus is to

offer a connection to an external BMS, or to a generic

external

device,

even

when

the

standard

communication bus (described in 2.5.6) is used for

dual pump operations (in case of a twin-head pump or

2x single-head pumps)

NOTICE

Don’t use this communication bus, implemented on

terminals

,

and

, for connecting 2 pumps in dual

pump operations

2.5.8 Optional wireless / RS485 module

[]

The drive can be equipped with

an optional Wireless module;

an optional RS485 module

Both the modules shall be plugged inside the drive

(see

), fixed by the provided clips and with

the cable connected to the connector (see par. 6.2

and 6.3).

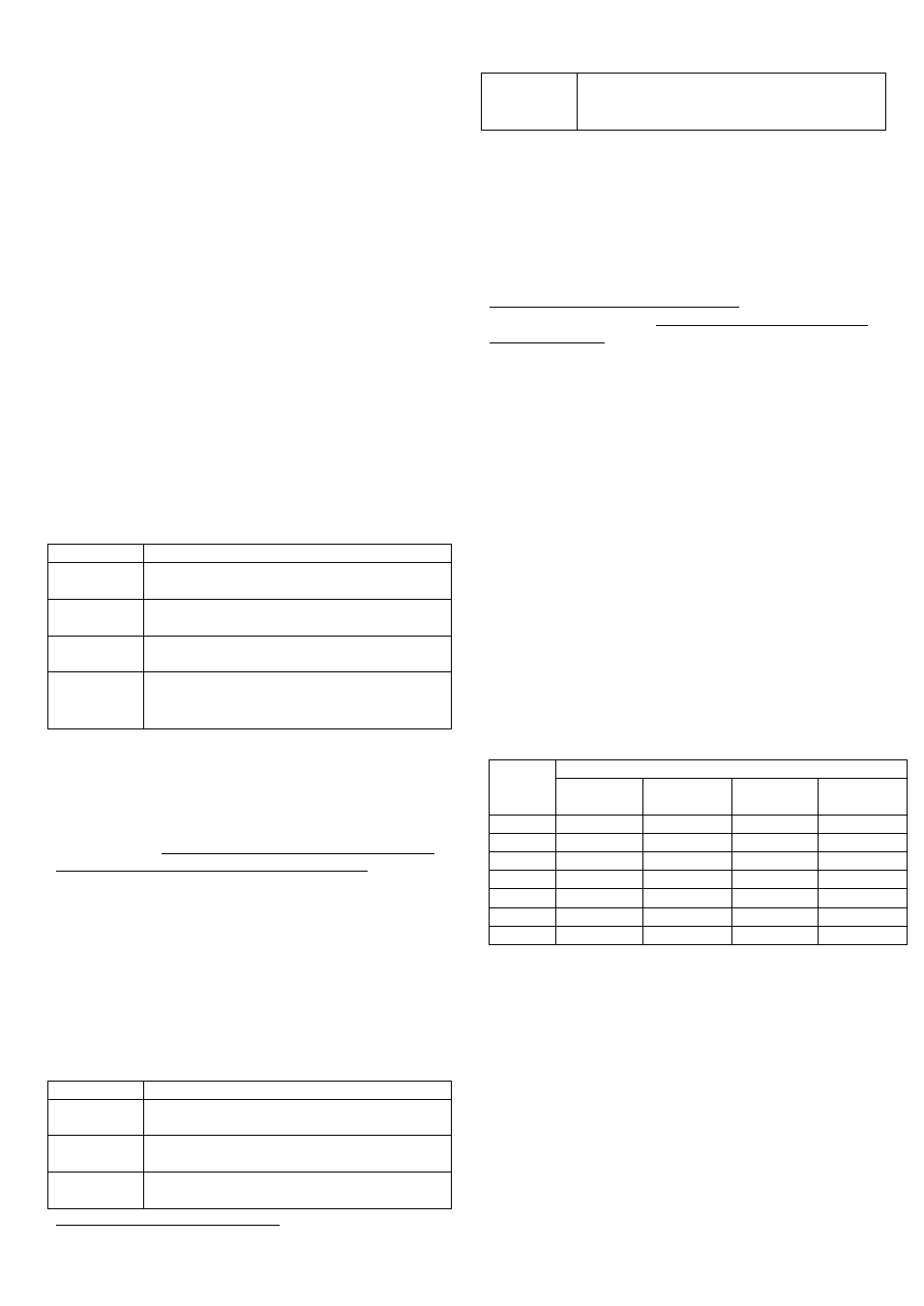

2.6 Settings priority

All the I/O signals, described in 2.5, can interact

together changing the behavior of the circulators they

are connected to: in particular, in case two or more

signals are enabled and active at the same time, the

circulator will operate according to the setting with the

highest priority.

Refer to the table below for the settings priority:

Priority

Possible settings

User

Interface

External

Start/Stop

External

0-10V

Bus signal

1

Stop

2

Regulation

3

Stop

4

Regulation

5

Stop

6

Regulation

7

Stop

EXAMPLE 1

In case the external start/stop switch is open or

unconnected (External Start/Stop = Stop), the drive

shall not accept any regulation.

EXAMPLE 2

The circulator can be driven through the User Interface

only if no external signals are applied (to the provided

terminals) and no communication bus is connected