Operational limits, Installation instructions, System venting and purging – Bell & Gossett V58911B Expansion Tanks for Hydronic Heating Systems User Manual

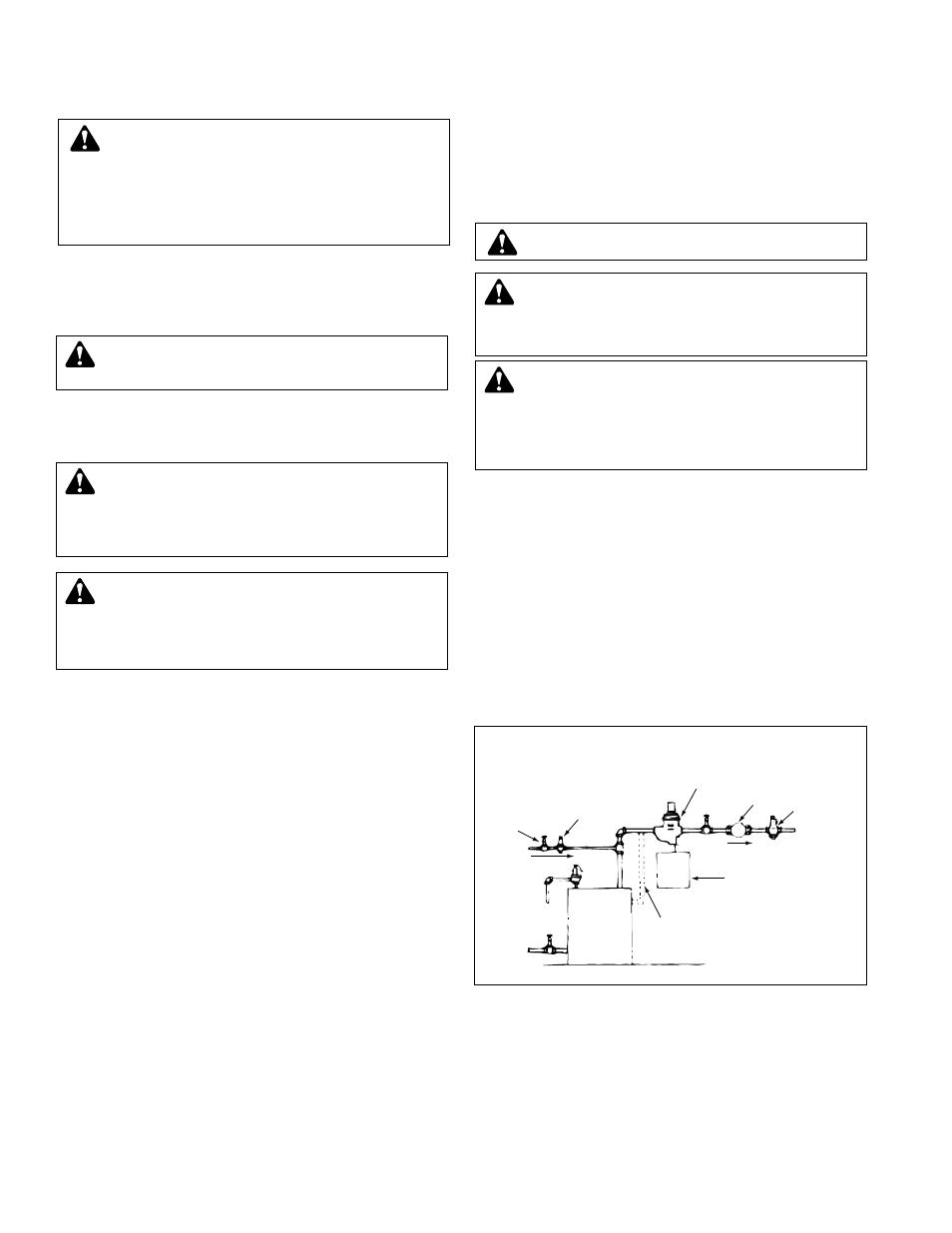

Page 2: Figure 2

OPERATIONAL LIMITS

Maximum Operating Pressure: 100 PSI.

Maximum Operating Temperature: 240ºF.

INSTALLATION INSTRUCTIONS

A. Pre-Installation

1. Visually inspect expansion tank and check for damage prior to

installation.

2. HFT tanks are factory precharged to 12 PSI, adjust pre-charge

to equal system fill pressure.

3. Replace and tighten plastic cap on air fitting.

B. Installation

The Series “HFT” may be installed into a tee or any other suitable

tapping on a water heating system, on the suction side of the circula-

tor. (see Figure 2).

It must be placed in a vertical position. It may also be remotely

located and piped to convenient point on the system. Do not install on

a dead end pipe or in an overhead joist space.

An ideal HFT tank installation is to screw it into the bottom of B&G air

separator (IAS, EAS or EASB-JR) located on the supply line. This

combination offers both control of expanded water and continuous

automatic air removal from the system.

After installing HFT tanks on the system:

1. Fill system.

2. Vent air from the system.

3. Bring system up to maximum operating temperature.

4. If an HFT tank is used with a volume smaller than required to

accommodate expanded water from a cold start to maximum

operating temperature, some preliminary expanded water must be

drawn from system to bring operating pressure down to normal

level. Drain water from boiler until pressure reads at maximum

range (25 PSIG).

Generally a smaller tank will cause a higher system pressure than

desired when system reaches operating temperatures. This

condition is normally referred to as a summer/winter installation

(boiler is always at temperature). Tank should be tagged to denote

this.

SYSTEM VENTING AND PURGING

After initial venting and purging of air from the system, more air will be

released from the water as it is heated. Therefore, it is recommended

that a B&G air separator be installed on the main.

If the system has multiple loops or zones, the supply water for all

loops and zones must pass through the air separator for complete and

continuous air removal. In case the piping arrangement does not

permit the installation of a single air separator on the main, air

separators should be installed on each loop or zone. In this event, only

one expansion tank is required for the system.

Even with a B&G air separator installed on the main or mains, it is

recommended that B&G air vents be installed on high points in the

system.

It is also recommended that a manual (key or coin type) air vents be

installed at higher points on the radiation.

WARNING: Rupture or Explosion Hazard

Like most pressurized tanks, this tank can over time

corrode, weaken, and burst or explode. Failure to follow this

instruction may result in serious personal injury or death and

property damage.

WARNING: Chlorine & Aggressive Water Warning

The water quality can significantly influence the life of your

product. You should test for corrosive elements, acidity, total

solids, and other relevant contaminants, including chlorine and

treat your water appropriately to insure satisfactory performance

and prevent premature failure. Failure to follow this instruction may

result in serious personal injury or death and property damage.

SHUT-OFF

VALVE

C.W. FILL

B&G RELIEF

VALVE

RETURN

BOILER

OPTIONAL

SIDE OUTLET

BOILER

CONNECTION

B&G PRESSURE

REDUCING VALVE

AIR SEPARATOR

B&G

BOOSTER

B&G

FLO-CONTROL

VALVE

TO

SYSTEM

DIAPHRAGM TYPE

EXPANSION TANK

“HFT”

FLOW

FIGURE 2

WARNING: CALIFORNIA PROPOSITION 65 WARNING!

Warning: This product contains a chemical known by the

State of California to cause cancer and to cause birth defects or

other reproductive harm. (California Installer/Contractor – California

law requires that this notice be given to consumer/end user of this

product.)

WARNING: System fluid under pressure and/or at high tem-

peratures can be very hazardous. Before servicing, reduce

system pressure to zero or isolate the vessel from the system.

Allow system to cool below 100°F and above 35°F. Failure to follow

this instruction may result in serious personal injury and/or property

damage.

WARNING: If the expansion tank is damaged, it must be

replaced. Failure to follow this instruction may result in

serious personal injury or death and property damage.

WARNING: This product, like most products under pressure,

may over time corrode, weaken and burst or explode,

causing serious or fatal personal injury, leaking or flooding and/or

property damage. To minimize risk, a licensed professional must

install and periodically inspect and service the Product. A drip pan

connected to an adequate drain must be installed if leaking or

flooding could cause property damage. Do not locate in an area

where leaking could cause property damage.

WARNING: Mount vertically only. Do not mount on dead-

end pipe.