Appendix c – Bell & Gossett S14141B 70X Multiple Pump Pressure Booster Systems User Manual

Page 10

10

APPENDIX C

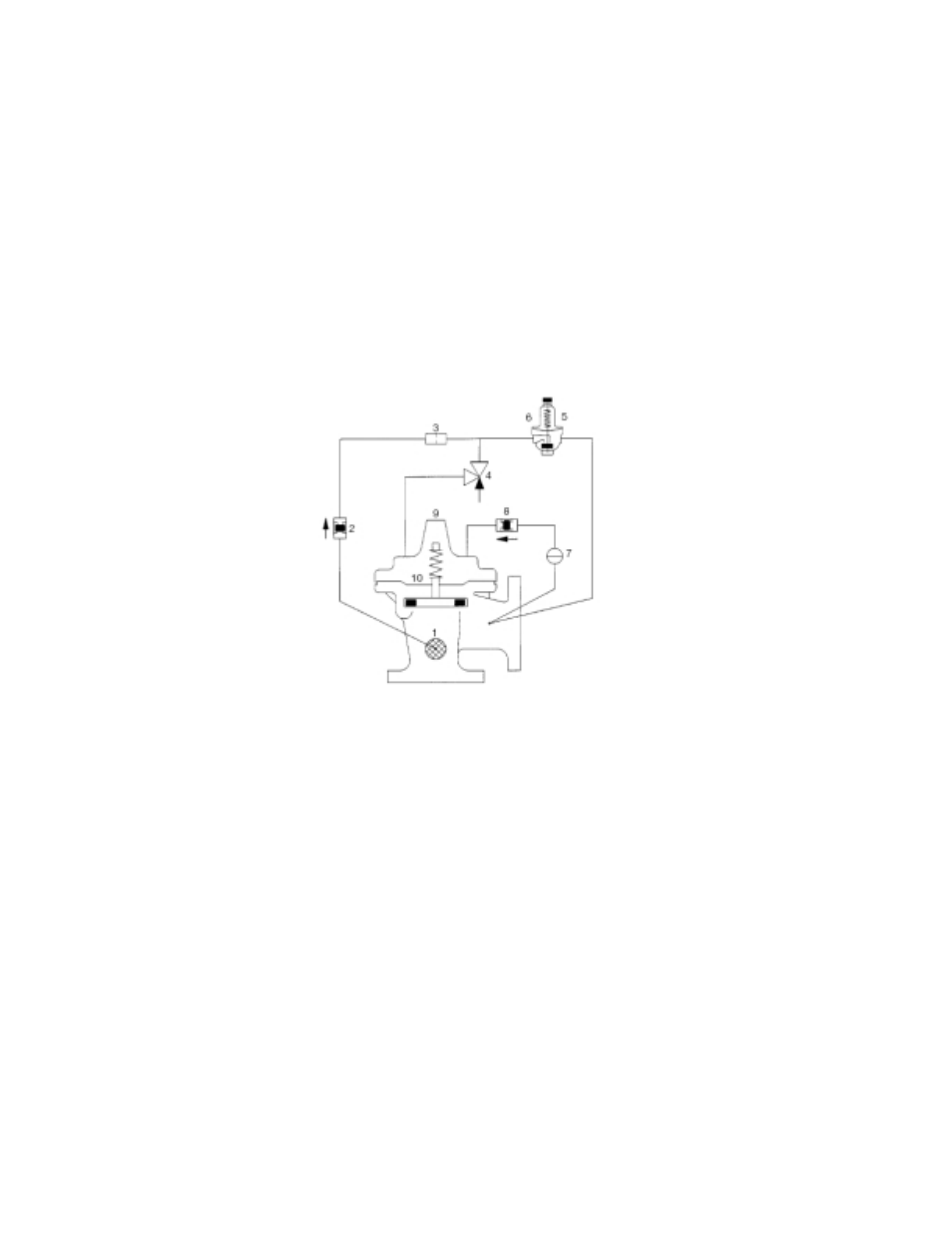

PROCEDURE FOR FIELD BALANCING PRESSURE REDUCING VALVE

COMBINATION PRESSURE REDUCING AND CHECK VALVE

Item

Name

Primary Function

1

Strainer

Prevents orifice from clogging

2

Check Valve

Prevents backflow from top of diaphragm when pumping stops.

3

Orifice

Provides metered water flow to top-side of diaphragm.

4

Opening Speed Flow Control

Dampens pressure fluctuations (slow opening).

5

CRD

Pilot PRV.

6

Gauge

Optional location for system pressure gauge.

7

Cock

Adjustment for rate of closure (non-slam).

8

Check Valve

Prevents backflow from top of diapgragm during normal operation.

9

Vent

Bleeds air from top of diaphragm.

10

Diaphragm

Divides inlet and outlet pressures.

Figure 2

1.0 Pressure Reducing valve (PRV) Adjustment

1.1

The pressure reducing valves are "factory set". If

needed, the following items should be checked

first before any attempt is made to change the

setting:

a) Does the desired system pressure correspond

to the pressure indicated on the nameplate?

b) Is the suction pressure equal to or higher than

the pressure indicated on the nameplate?

c) Is the demand (GPM) within the capacity indi-

cated on the nameplate?

d) Has the PRV been properly vented?

1.2

Any deviation from the above conditions will pre-

vent the unit from operating at the factory (name-

plate) settings.

1.3

To adjust the PRV place the pump in manual oper-

ation per Technologic 500X instruction manual.

With the pump now running, slowly close the main

gate valve downstream of the discharge header

allowing a trickle of water to flow through it. Read

the system pressure on the display. It should read

3 or 4 psi higher than the desired system pres-

sure. If not, remove the protective cap on the pilot

control valve and loosen the jam nut on the

adjusting stem of the PRV. Slowly turn the stem

clockwise to increase the delivery pressure and

counter clockwise to decrease pressure. (Note

that a pilot valve furnished for a 20 to 300 psi

range will change the main valve setting approxi-

mately 28 psi for each full turn of the adjusting

screw.) Set the screw so the system display reads

3 to 4 psi higher than the desired system pressure.

1.4

Open the gate valve fully. If feasible, draw be-

tween 50 to 80% of the designed pump capacity

to recheck valve setting. The display should now

read the desired system pressure. Tighten jam

nut and replace cap.

1.5

Repeat the above procedure for all pump and

valve combinations as required.

1.6

The CV Flow Control Valve (opening speed con-

trol) may require field adjustment if pressure hunt-

ing occurs. Normal setting of the valve is from 4 to

7 turns open. Never open more than 8 turns.