Reassembly, Seal assembly, Assemble the single mechanical seal (e-1532-s) – Bell & Gossett P2001409A Series e-1532 User Manual

Page 27

• Thoroughly clean the shaft and sleeve.

• Thoroughly clean the coverplate seal cavity.

• Inspect the surface for damage such as pitting, corrosion, nicks, and scratches.

Replace these parts if they are damaged.

Reassembly

Seal assembly

Assemble the standard mechanical seal (e-1532 and e-1532-F)

1. Lubricate the shaft sleeve and coverplate seal cavity with soapy water.

Do not use a petroleum lubricant.

2. Install a new cup gasket and a new seal insert with the indentation side down into the

cup.

3. Slide a new rotating seal assembly onto the shaft sleeve.

4. Push the top of the compression ring with a screwdriver until the seal is tight against

the seal insert.

5. Install the seal spring and point the narrow end toward the seal.

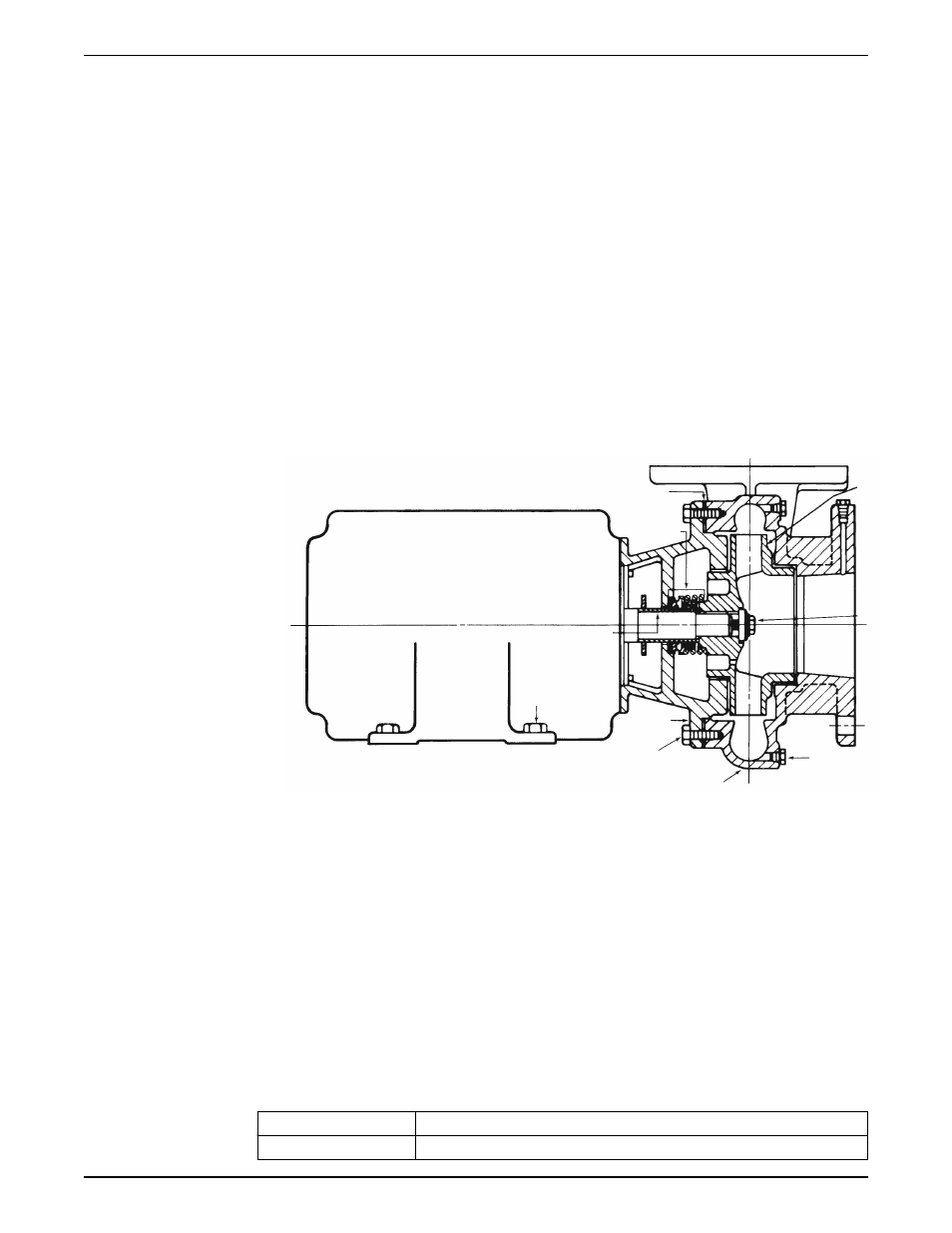

1

2

3

4

5

6

7

8

9

10

1.

Impeller

2.

Impeller capscrew

3.

Drain plug

4.

Volute

5.

Volute capscrews

6.

Motor bracket

7.

Motor foot capscrews

8.

Shaft sleeve

9.

Seal assembly

10. Volute gasket

Assemble the single mechanical seal (e-1532-S)

1. Lubricate the shaft sleeve and seal cap with soapy water.

Do not use a petroleum lubricant.

2. Insert a stationary seal with an O-ring into the seal cap and slide it onto the shaft.

3. Replace the seal cap gasket.

4. Slide the rotating portion of the seal assembly onto the shaft sleeve and lock it in

place.

ID seal size

Distance between collar and impeller end of the shaft sleeve

1-1/4 in. (3.175 cm)

1-13/32 in. (3.571 cm)

Maintenance

Series e-1532 INSTRUCTION MANUAL

25