Pre-assembly inspections, Shaft and sleeve inspection – Bell & Gossett P2001409A Series e-1532 User Manual

Page 26

Balancing

It is recommended that impellers trimmed more than 5% in diameter be rebalanced per

ISO 1940 grade G6.3.

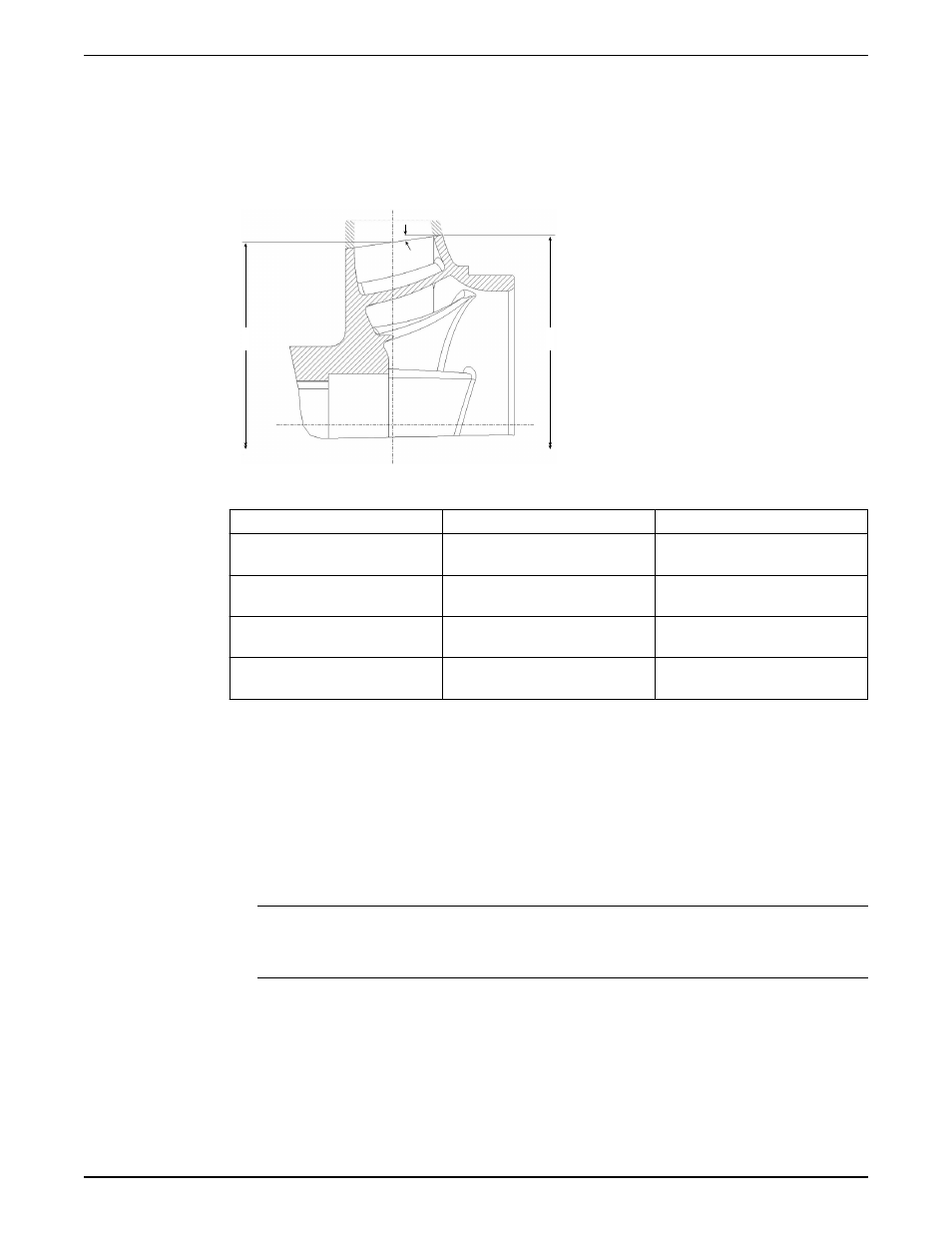

Angle cut guidelines

Model e-1532-4AD pump impellers must be angle cut at reduced diameters according to

the following information.

ØA

ØB

C

Figure 4: 4AD impeller trim — 0.125 in. (3.17 mm) increments

A

B

C

Hydraulic diameter, nominal, as

shown on selection curves

Diameter at impeller inlet side

shroud

Trim angle

From maximum diameter 7 in.

(177.8 mm) to 6.125 in. (155.6 mm)

Use diameter from selection curves

0 degrees, no angle

6, 5.875, 5.75, 5.625 in. (162.4 to

142.9 mm)

B = A plus 0.250 in. (6.35 mm)

8 degrees

5.5, 5.375, 5.25, 5.125, minimum 5

in. (139.7 to 127.0 mm)

B = A plus 0.375 in. (9.53 mm)

8 degrees

Pre-assembly inspections

Guidelines

Before you assemble the pump parts, make sure you follow these guidelines:

• Inspect the pump parts according to the information in these pre-assembly topics

before you reassemble your pump. Replace any part that does not meet the required

criteria.

• Make sure that the parts are clean. Clean the pump parts in solvent in order to remove

oil, grease, and dirt.

NOTICE:

Protect machined surfaces while you clean the parts. Failure to do so may result in

equipment damage.

Areas to inspect

Inspect the pump regularly for leaking seals, worn gaskets, and loose or damaged

components. Replace or repair these parts as required.

Shaft and sleeve inspection

Inspection criteria

Inspect the shaft and sleeve according to this criteria:

Maintenance

24

Series e-1532 INSTRUCTION MANUAL