Mounting – Xylem 704 PUMP CONTROLLER User Manual

Page 9

9

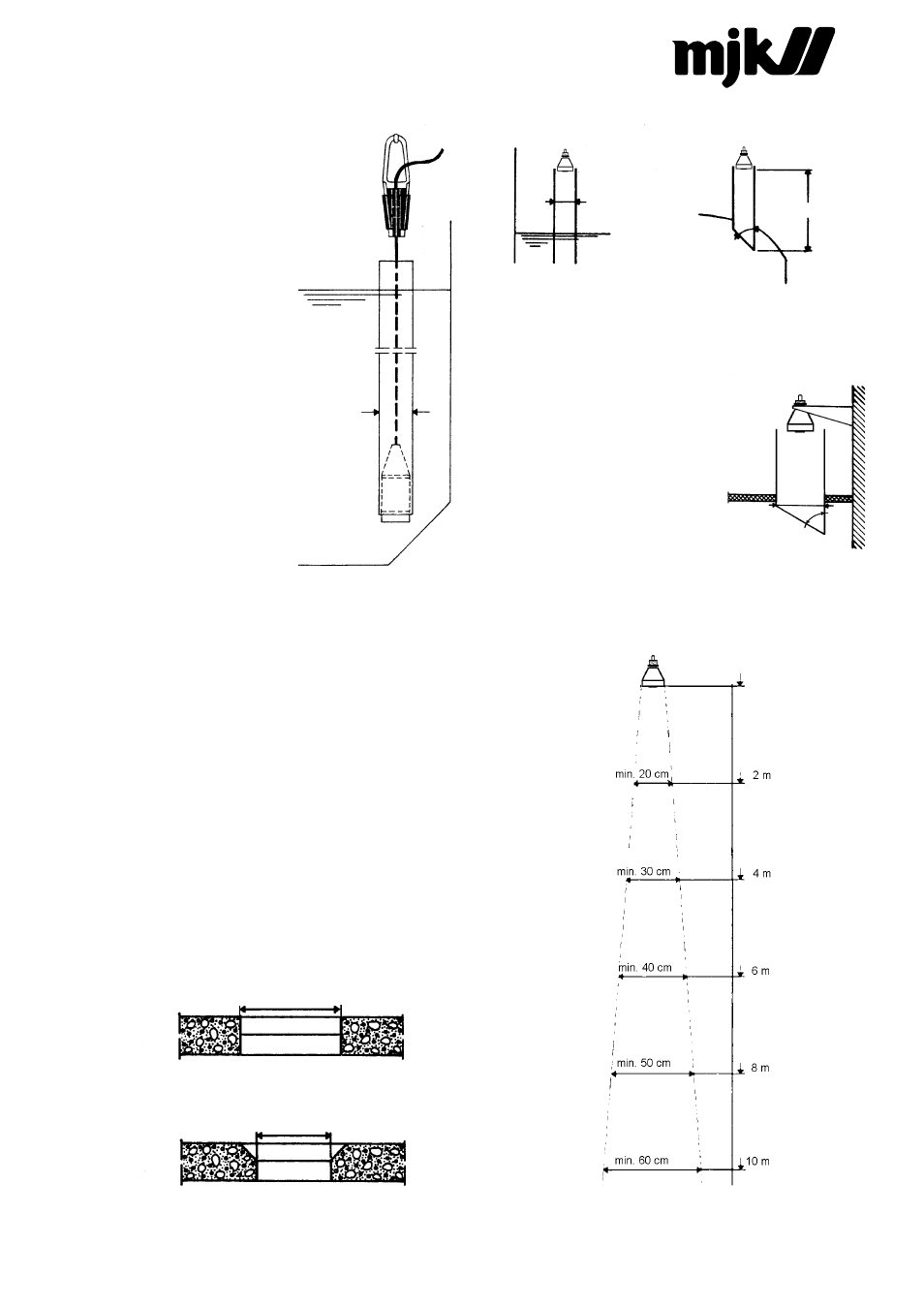

Table values for the signal

spreading relative to sensor/

surface distance.

Mounting

Pressure Transmitter

When measuring in a well, it

is advantageous to mount

the transmitter in a tube,

fastening it at the top of the

tube by means of the fittings

supplied. This mounting

facilitates subsequent

cleaning and inspection.

Ultrasonic Sensor

When mounting the sensor for example at the top of a

well or a container, ensure that no pipes or cables etc.

are disturbing the path between the sensor and the liquid

surface. The maximum distance between the sensor and

the surface must not exceed the measuring range of the

transmitter. Optimum operation is obtained by placing the

sensor approx. 1 m (3 ft) for 30 kHz sensor, and approx.

0.5 m (1,7 ft) for the 100 kHz sensor, above the

maximum liquid level. The sensor should be positioned

perpendicular to the liquid surface (check with a spirit

level!). When installing the sensor, ensure that the signal

is able to pass any obstruction, taking in consideration

that signal spreads relative to the sensor/surface distance

as described in the table. If the signal travels along a

hard surface such as the side of a well or tank, the table

values can be applied directly. Otherwise you may refer

to the following mounting examples.

If a sensor is mounted above an obstruction ex. a

concrete deck, we recommend that it should be installed

as shown below:

Tube-mounted pressure

transmitter

If the upward edges on the obstruction are angled as

shown below, the sensor can be mounted as the

following:

Sensor mounted in tube

for scum protection.

Sensor mounted near the

top of a closed container.

When measuring

through a hole in

for example a

metal plate or

grate, a pipe that

ends near the

lower edge of the

sensor should be

applied as shown

here:

Min. table

value +100%

Min. 25in (30kHz)

Min. table

value

+25%

30 - 45

o

45

o

Min. table value +100%

Min. table value +50%