Xylem H-3553 User Manual

Page 9

Using a SDI-12 master device, like the XL series DCP, send the “0M!” measurement command to the H-3553.

Wait about 6 seconds, and then send the “0D0!” data command and verify the data retrieved with the example

below.

Data format: “a + A.AA + B.BBB + CC.C + DD.D + E.EE + FF.F”

a = SDI-12 sensor address

A.AA = Stage (Feet)

B.BBB = Pressure (PSI)

CC.C = Temperature (°C)

DD.D = Sensor Interface Battery (Volts)

E.EE = Tank Pressure (PSI)

F.FF = Compressor Battery (Volts)

Example: “0 + 1.35 + 0.585 + 19.8 + 13.6 +

3.55 + 12.3”

Getting Started

7

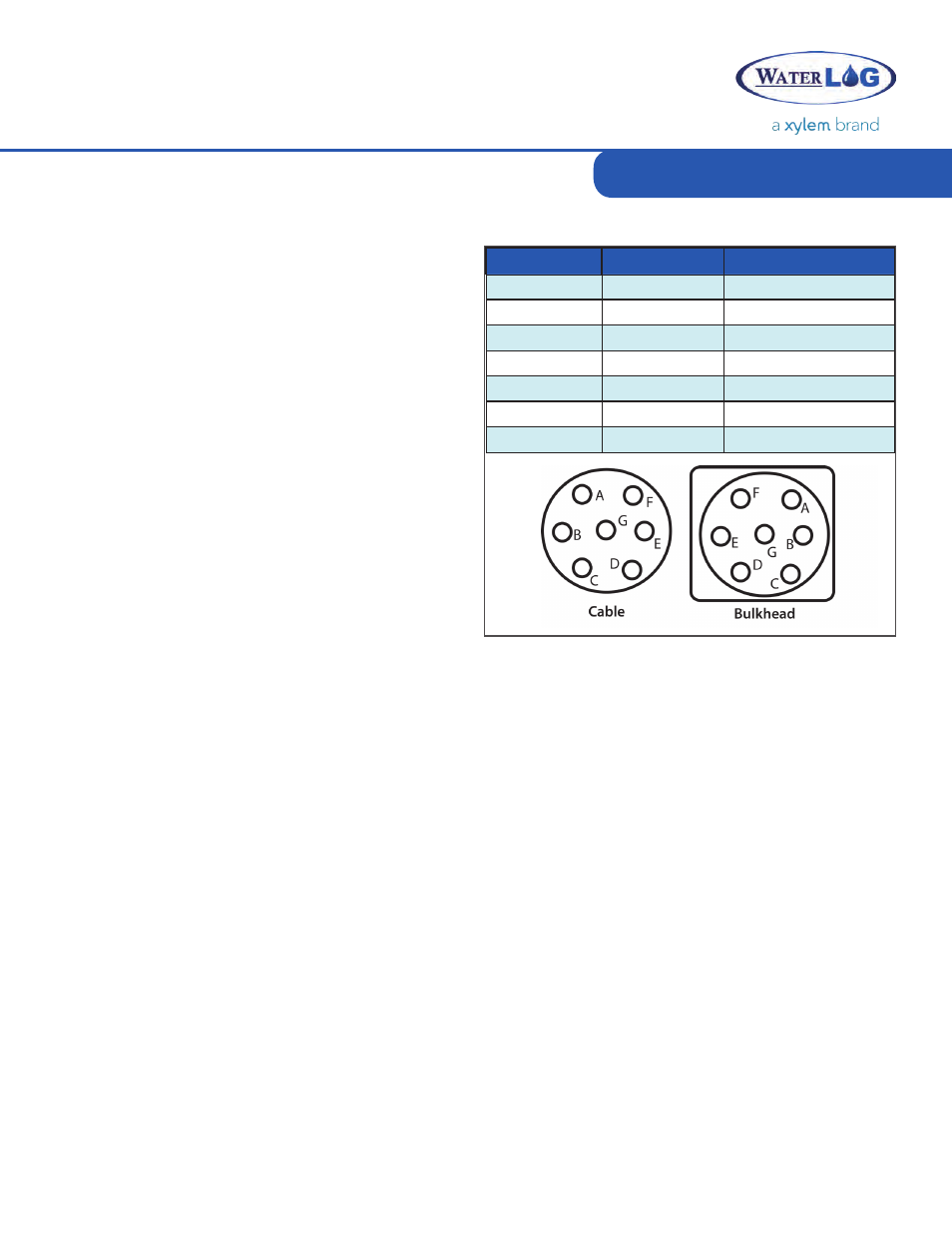

Colors

signal

Cable/Bulkhead

Red

+12 VDC

F

Black

GND

E

Yellow

SDI-12 Data

G

Blue

4-20mA +

C

Green

4-20mA -

D

Orange

RS-485+

A

Brown

RS-485-

B

Table 2-1: Main I/O Sensor Interface Cable

The H-3553s display has a ‘Read’ button that

when pressed will cause the unit to initiate a new

measurement and update the display. Measurement

requests from an attached SDI-12 data logger will

also cause the display to update.

If the ‘Read’ button is pressed and held until

the display starts flashing, the Adjust screw may

be turned to increase or decrease the current

stage value. Turning the Adjust screw slowly

will change the hundredths (or thousandths

based on the digit setting) digit while turning

the screw fast changes the ones digit. This

allows one control to make both fine and course

adjustments.

If the ‘Read’ button is held down while the

H-3553 is being powered up, the display will

show the current SDI-12 address. The SDI-12

Using the Display

address may be changed using the Adjust screw. Turning the Adjust screw will change the address

in the range of 0 to 9. When the Read button is released the new SDI-12 address is saved and the

display switches to the normal stage readout. To change the SDI-12 address again, the power must

be disconnected and the special power-up sequence repeated.

When the ‘Purge’ button is pressed a new measurement will be initiated; following the

measurement, a line purge will begin. For more information see the Purge section in Chapter 4.

When the ‘Tank Release’ button is pressed the valve holding the air in the tank will be opened,

allowing the air stored in the tank to be released. This button can be useful when troubleshooting

the unit.

Make Measurement