Setup & operation – Xylem H-3553 User Manual

Page 22

SETUP & OPERATION

20

Purge

The H-3553 has an option built in called purge, the purpose of the purge

is to clear out any debris or silt from the end of the orifice line that could cause false pressure readings.

When a purge is initiated the H-3553 makes a new measurement on the line and tank sensor and saves the

values away just in case data is requested during the purge. The compressor is then turned on and begins

compressing air into the tank until the tank pressure is equal to or greater than the purge pressure value.

The purge valve is then opened which then releases the tank pressure into the orifice line. The compressor

will continue to run until the purge sustain timer has elapsed. Then the H-3553 monitors the tank pressure

which is still open to the orifice and waits for it to stabilize. Finally, the purge valve closes and the H-3553

purge process is complete. Shortly following the purge sequence the H-3553 will need to recharge the tank

pressure to maintain the bubble rate and continue normal operation.

There are three ways to initiate a purge, push the “PURGE” button, the RS-232 menu, and the SDI-12 interface.

To initiate a purge with the button, open the H-3553 enclosure lid and locate the a white push button on the

circuit board labeled “PURGE”, press and hold for about 2 seconds.

To initiate a purge using the RS-232 main menu, press ‘B’ key to enter the “Bubbler Settings” menu and then

press the ‘M’ key for “Manual Purge”. To initiate a purge using the SDI-12 interface, send the “aXP!” command

or the “aM2!” command. Note Table 4-14, the ‘a’ is the current SDI-12 address of the H-3553. The ‘ttt’ is the

time it will take to complete the purge, which is dependent on other factors like averaging time and purge

sustain. The ‘dd.d’ is the compressor battery voltage measured immediately following the completed purge

sequence.

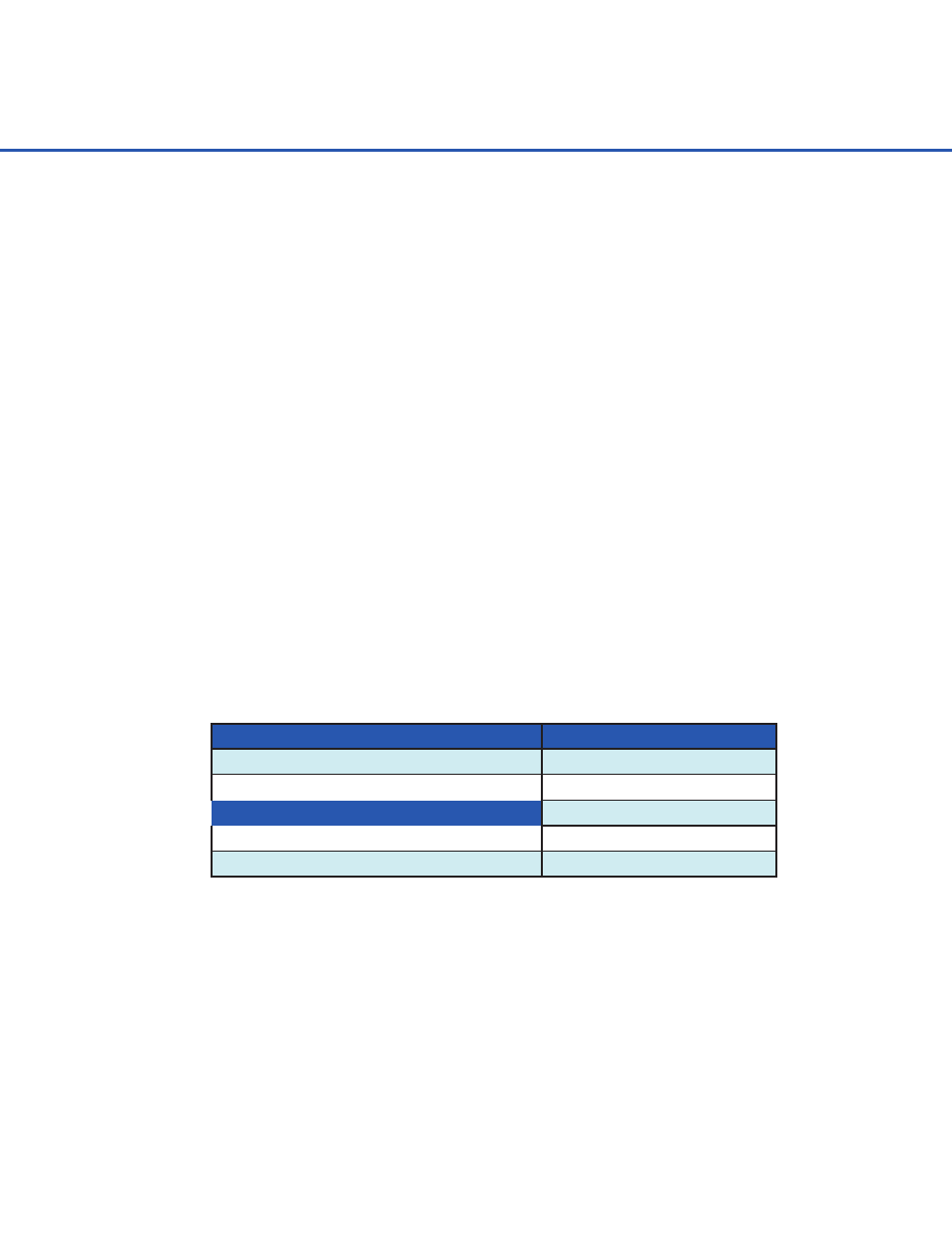

H-3553 Combo Bubbler setup menu

sDI-12 Interface

B – Bubbler Settings

Command: aXP! / aM2!

:

Response: attt1

Bubbler settings menu

Command: a + dd.d

M – Manual Purge

Response: a + dd.d

Initiating Purge . . .

Table 4-14: Initiate H-3553 Purge

Purge Pressure

The purge pressure is the pressure that is used to purge the orifice line. This is normally done to clear the end

of the orifice line of debris and or sediment buildup. “False high stage” readings can be caused by debris or

sediment buildup at the end of the orifice line. This is because it will cause more restriction when trying to

push a bubble out which is like the stage is rising. This may cause a saw tooth profile in your data. As pressure

keeps building up until the bubble pushes out past the debris or sediment relieving the pressure in the line.

Then the pressure starts building up again causing saw tooth data.

The H-3553 purge pressure default is set to 40 PSI (15 PSI sensor) or 50 PSI (30 PSI sensor). The programmable

purge pressure range is 30 to 90 PSI. To change the “Purge Pressure” using the RS-232 main menu, press the