YSI Pro2030 User Manual

Page 20

32

33

Thread the cap membrane onto the sensor. It is normal for

a small amount of electrolyte to overflow.

Replace the sensor guard.

Polarographic Sensors – Model # 605203

The cap membrane and KCl (potassium chloride) electrolyte solution should be

changed every 2-4 weeks during regular use. In addition, the electrolyte solution

and membrane should be changed if (a) bubbles are visible under the membrane;

(b) significant deposits of dried electrolyte are visible on the membrane; and (c)

if the sensor shows unstable readings or other sensor-related symptoms.

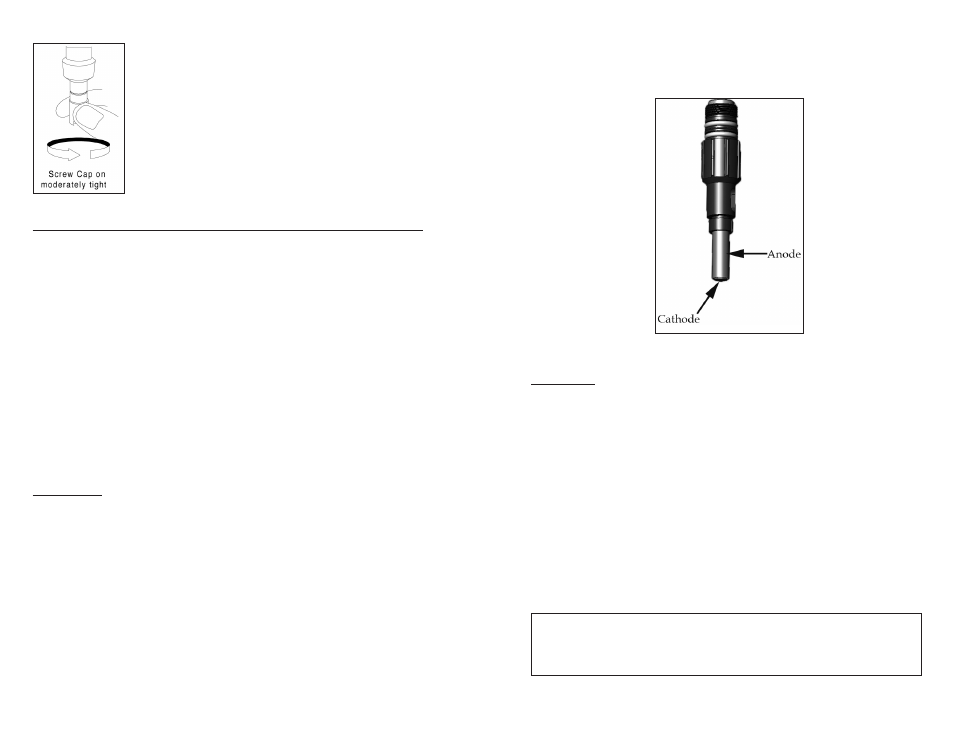

During membrane changes, examine the gold cathode at the tip of the sensor and

the silver anode along the shaft of the sensor (figure 12). If either the silver anode

is black in color or the gold cathode is dull, the sensor may need resurfaced using

the 400 grit wet/dry sanding discs included in the membrane kit. Do not sand

the electrode every membrane change as this is not routine maintenance. In fact,

visually, the anode may appear tarnished and operate properly. YSI recommends

using the sanding disc if the sensor has difficulty stabilizing or calibrating after

a regular membrane change.

To clean and resurface the sensor, follow the instructions on the next page.

Gold Cathode

For correct sensor operation, the gold cathode (figure 12) must be textured

properly. It can become tarnished or plated with silver after extended use. Never

use chemicals or abrasives that have not been recommended or supplied by

YSI.

First dry the sensor tip completely with lens cleaning tissue. Wet a sanding disc

and place it face up in the palm of you hand. Next, with your free hand, hold

the sensor in a vertical position, tip down. Place the sensor tip directly down on

the sanding disc and twist it in a circular motion to sand the gold cathode. The

goal is to sand off any build-up and to lightly scratch the cathode to provide a

larger surface area for the electrolyte solution under the membrane. Usually, 3 to

4 twists of the sensor are sufficient to remove deposits and for the gold to appear

to have a matte finish. Rinse the sensor thoroughly with distilled or deionized

water and wipe the gold cathode with a wet paper towel before putting on a new

cap membrane. If the cathode remains tarnished, contact YSI Technical Support

or the YSI authorized dealer where you purchased the instrument.

Figure 12, DO sensor with membrane removed.

Silver Anode

After extended use, a thick layer of Silver Chloride (AgCl) builds up on the

silver anode (figure 12) reducing the sensitivity of the sensor. The anode must

be cleaned to remove this layer and restore proper performance. The cleaning

can be chemical and/or mechanical:

Mechanical cleaning: In order to sand the silver anode along the shaft of the

sensor, simply hold the sensor in a vertical position. Wet the sanding disc and

gently wrap it around the sensor and twist it a few times to lightly sand the anode

(the goal is to simply sand off any build-up without scratching or removing

layers of the anode itself). Usually, 3 to 4 twists of the sanding disc are sufficient

to remove deposits.

After completing the sanding procedure, repeatedly rinse the electrode with

distilled or deionized water and wipe with lens cleaning tissue to remove any

grit left by the sanding disc. Thoroughly rinse the entire tip of the sensor with

distilled or deionized water and install a new membrane.

IMPORTANT: Be sure to: (1) Use only the fine sanding discs provided

and (2) Sand as mentioned in the above procedures. Not adhering to

either of these instructions can damage the electrodes.

i