Xylem IMVIC R01 Model VIC Vertical Industrial Turbine Can Pumps User Manual

Page 9

9

Installation – SECTION 3

When pumping unit is installed in a potentially

explosive environment, the instruction after

the symbol must be followed. Personal

injury and/or equipment damage may occur if these

instructions are not followed. If there is any question

regarding these requirements or equipment is to be

modified, please contact a Goulds Water Technology

representative before proceeding.

FOUNDATION AND PIPING

SUB BASE (SOLE PLATE) OR BARREL FLANGE

INSPECTION

Sub base and sole plate are terms in common use to

describe a general class of solid steel plates mounted

in grout (or bolted to steel structures) at the pump-

foundation interface.

1. Remove the sub base from the pump discharge head

or barrel flange, when shipped assembled.

2. Completely clean the underside of the sub base. It is

sometimes necessary to coat the underside of the sub

base with an epoxy primer. (This is available as an

option.)

3. Remove the rust preventative solution from the

machined topside with an appropriate solution.

SITE WITH CONCRETE FOUNDATION

1. A pump should have adequate space for operation,

maintenance, and inspection.

2. Sub base mounted pumps are normally grouted

on a concrete foundation, which has been poured

on a solid footing. The foundation must be able to

absorb any vibration and to form a permanent, rigid

support for the pumping unit.

3. The foundation must be of adequate strength to

support the complete weight of the pump, plus the

weight of the liquid passing through it. A typical

installation will have bolts with a pipe sleeve 2 ½

times the bolt diameter embedded in the concrete.

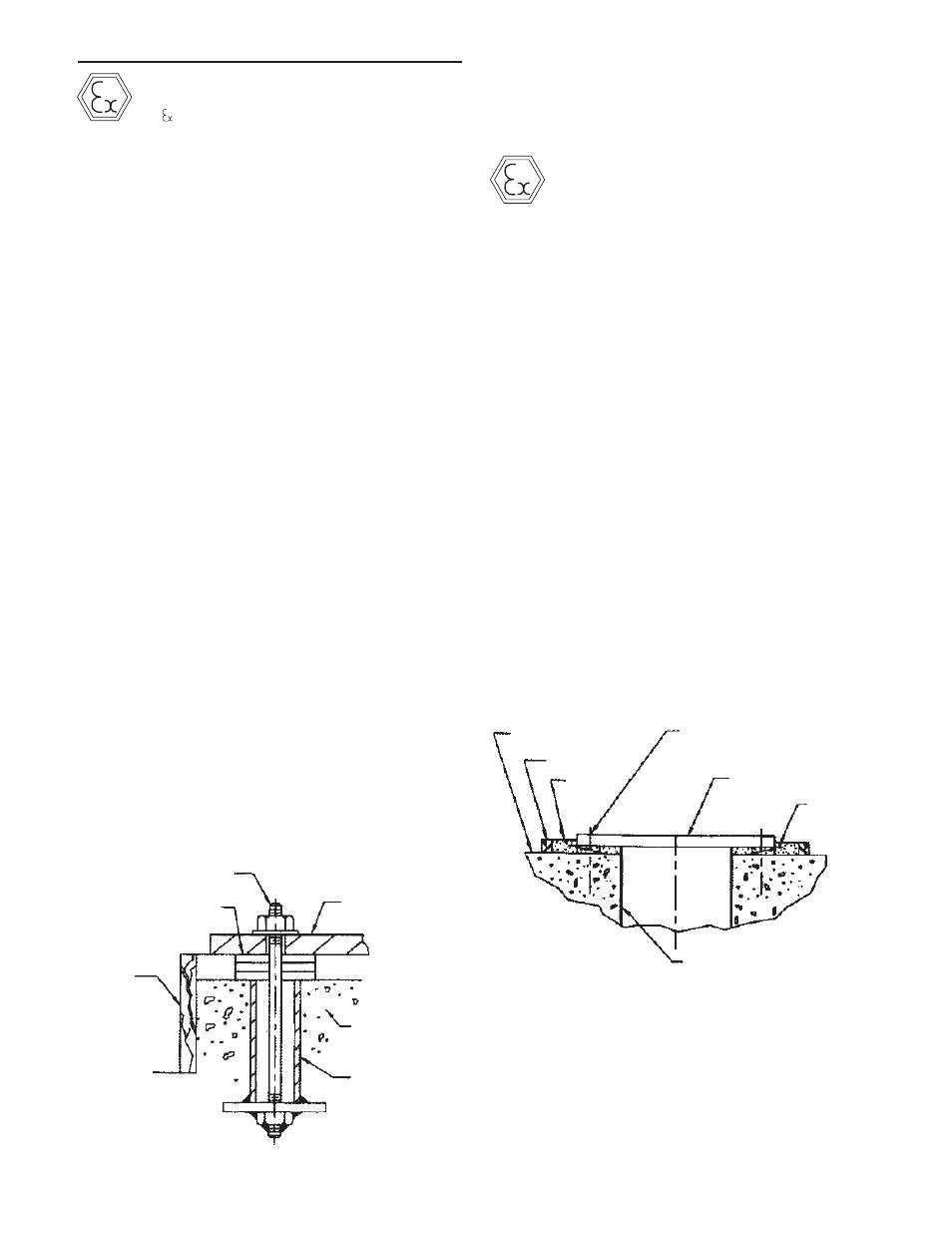

Figure 3

Bolts should be sized and located in accordance

with the dimensions given on the Certified Pump

Outline Drawing, if provided. The pipe sleeve

allows movement for the final positioning of the

foundation bolts to conform to the holes in the sub

base flange. See Figure 3.

All equipment being installed must be properly

grounded to prevent unexpected static electrical

discharge. If not, a static electric discharge may

occur when the pump is drained and disassembled for

maintenance purpose.

4. Remove water and/or debris from anchor bolt holes/

sleeves prior to grouting. If the sleeve type bolts are

being used, fill the sleeves with packing or rags to

prevent grout from entering.

5. Carefully lower the sub base onto the foundation

bolts. Hand tighten the nuts.

6. Leveling the sub base may be done by several

methods. Two common methods are:

A. Using leveling wedges. This is shown in Figure 4.

B. Leveling nuts on the anchor bolts.

Regardless of the method, a machinist level must be

used for leveling.

NOTE: When using a machinist level, it is important

that the surface being leveled is free of all

contaminants, such as dust, to ensure an

accurate reading.

7. Level the sub base in two directions at 90º on the

machined surface. The levelness tolerance is 0.005

inches per foot for commercial, and 0.001 inches

per foot for API.

Figure 4

SUB BASE OR BARREL FLANGE GROUTING

1. Inspect foundation for dust, dirt, oil, chips, water,

etc. and remove any contaminants. Do not use oil-

based cleaners as grout will not bond to it. Refer to

grout manufacturer’s instructions.

2. Build dam around foundation (See Figure 4).

Thoroughly wet foundation.

BOLT

SHIMS

DAM

SUB BASE

FOUNDATION

SLEEVE

SUB BASE

FOUNDATION

DAM

GROUT

CENTERLINE

ANCHOR BOLT

LEVELING

WEDGES

FLOOR SLEEVE

(OPTIONAL)