Xylem IMVIC R01 Model VIC Vertical Industrial Turbine Can Pumps User Manual

Page 11

11

1. Prior to installing the bowl assembly, check that

all capscrews are tight. Turn the pump shaft by

hand and make sure it turns freely. Remove all

accumulated dust, oil, or other foreign material

from the external surfaces.

2. If a suction strainer is provided, assemble it to the

suction bell (or suction bowl).

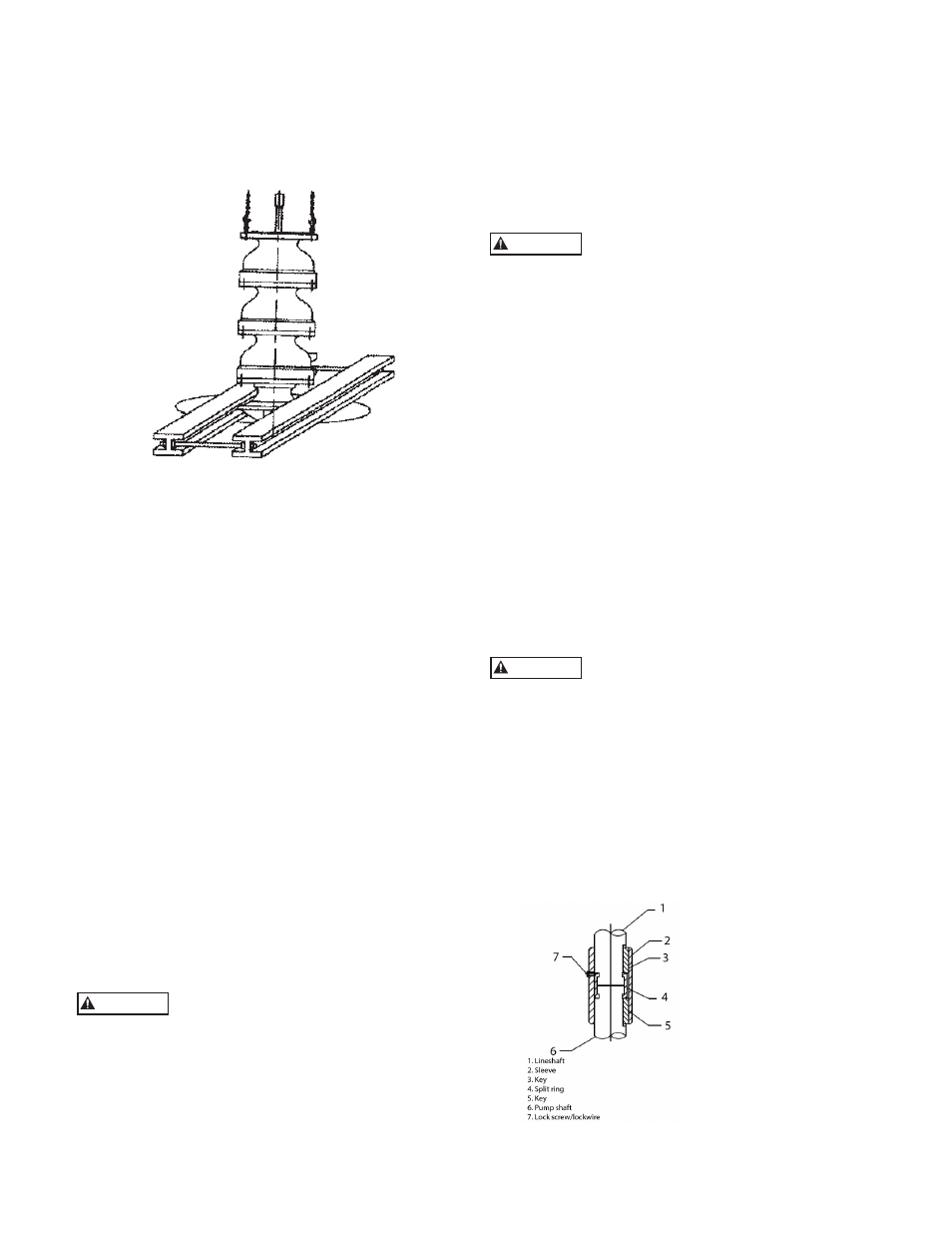

Figure 5

3. Place two I-beam supports across the base plate

opening, strong enough to safely support the weight

of the entire pump assembly. These I-beams should

be connected by threaded rods and nuts so as to

clamp them firmly together for the portion to be

supported. (See Figure 5).

4. Place a suitable hoist or derrick over base plate

opening with the hook in the center. Place the

elevator clamps just below the discharge bowl. Place

the elevator clamps just below the discharge bowl.

For flanged column install two threaded eyebolts

through the discharge bowl bolt holes 180º apart

for flanged column. For threaded discharge utilize

a lifting bail sized to handle the weight of the bowl

assembly and suction apparatus. Attach a sling to the

elevator clamps, eyebolts, or lifting bail and hoist it

into position.

5. Carefully lower bowl assembly, guiding the unit so it

does not strike the sides of the opening. Continue

to lower bowl assembly until the elevator clamps

or discharge bowl flange rests firmly on the I-beam

supports.

6. Place a cover over the discharge bowl opening to

prevent entrance of dirt or other foreign matter

until ready for installation of the column assembly.

Do not drop any foreign object into the

bowl assembly. Such an object can cause

serious damage to the pump and any downstream

components. Any foreign object dropped into the bowl

assembly must be retrieved prior to continuing assembly.

THREADED COUPLING INSTALLATION

NOTE: Shaft threads are left-handed.

When the threaded coupling is not installed on the

pumpshaft, install as follows:

1. Coat a thin film of oil to the threads on the lineshaft

(646) and the coupling (649) (for non-galling

material, or Molykote if galling material).

2. Install threaded coupling onto pumpshaft by

threading it on for one-half its length. A fine

wire inserted in the drill hole at the center of the

coupling can be used as a gauge to determine

when the coupling is correctly positioned on the

pumpshaft. Remove the wire after installed the

coupling.

Use “MOLYKOTE” Dow Corning or

equal for all galling material such as 316

stainless steel.

INSTALLING THE COLUMN

OPEN LINESHAFT

Pump lineshafts are coupled with either threaded

or keyed couplings. Follow only those procedures

appropriate for the type of lineshaft coupling supplied.

When provided, see the Certified Pump Outline Drawing

for the number of column and shaft sections required.

1. Check the headshaft (608) and lineshaft (646) for

straightness. Average total runout should be less

than 0.0005” T.I.R. per foot, not to exceed 0.005”

T.I.R. for every 10 feet of shafting.

2. Hoist the first piece of lineshaft over the bowl

assembly. Lower the lineshaft until the bottom end

is properly aligned with the coupling of the pump

shaft. Apply a thin film of oil to the threads on the

lineshaft (646) and the coupling (649) (for non-

galling material, or Molykote if galling material).

Use “MOLYKOTE” Dow Corning or

equal for all galling material such as

316 stainless steel.

3a. With lineshaft in the proper position on the

coupling, screw lineshaft into the coupling manually

until resistance is felt. A fine wire inserted in the

hole at the center of the coupling can be used as a

gage to determine when the coupling is correctly

positioned on the shaft. Remove the wire after

installing the shaft. Completely tighten the joint

by using a pair of pipe wrenches. Use care not to

damage any bearing journal areas on the shaft.

NOTE: Shaft threads are left-handed.

3b.

With a keyed coupling

insert the key into the

pump shaft. Lower the

sleeve over the pump shaft,

to approximately 1.0 in

(25.4 mm) below the top

of the shaft. Then lower

the lineshaft until it touches

the pump shaft. Insert the

split ring into the grooves

of the pump shaft and

lineshaft. Raise the sleeve

until it covers the split ring,

then insert the key into the

lineshaft. Raise the sleeve to the top of the key and

secure the sleeve to the split ring with a lock screw

and lock wire.

CAUTION

CAUTION

CAUTION