Xylem IMVIC R01 Model VIC Vertical Industrial Turbine Can Pumps User Manual

Page 14

14

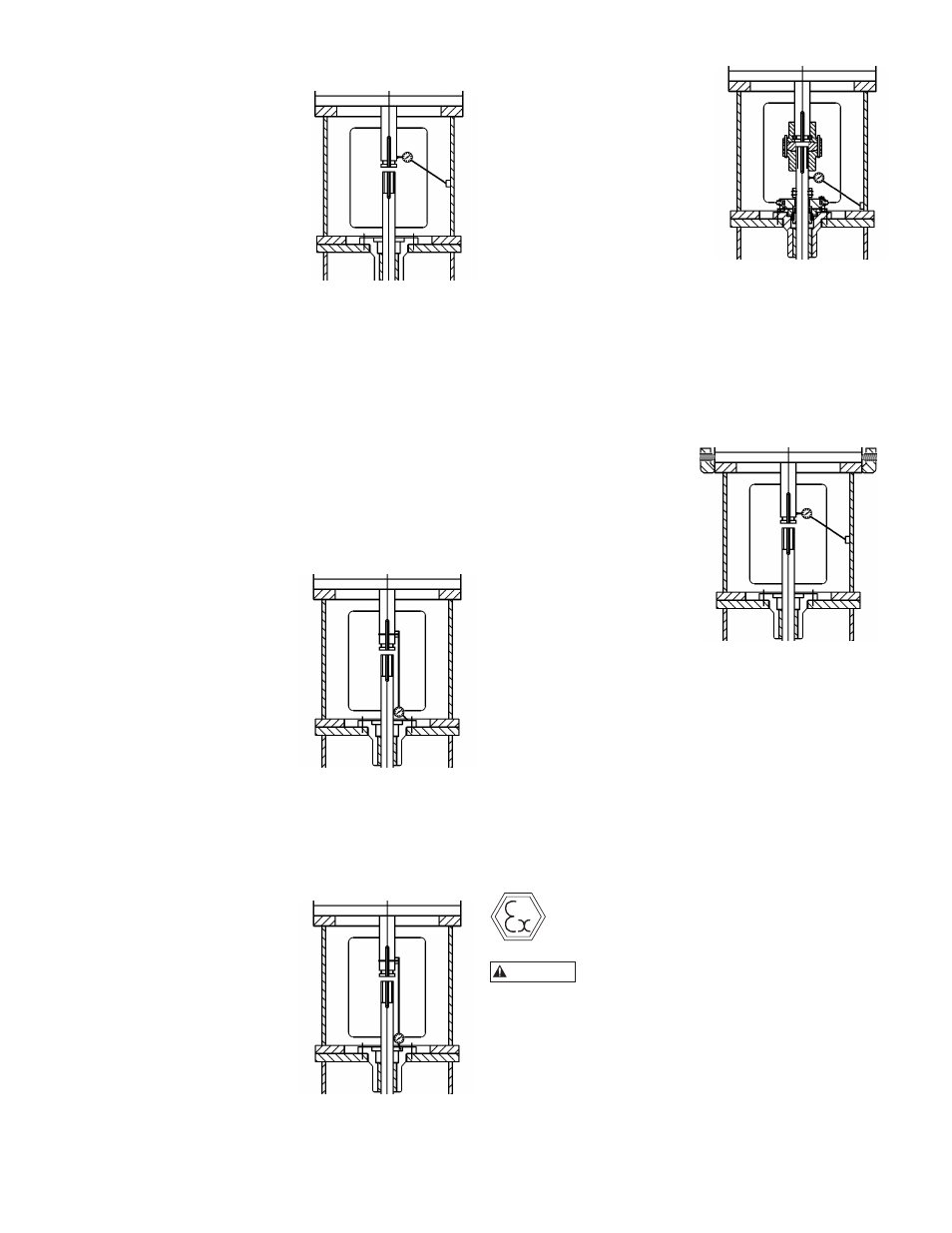

MECHANICAL SEAL ALIGNMENT

CONCENTRICITY OF MOTOR SHAFT

1. Install the dial indicator as

shown, with the base attached

to the motor support.

2. Rotate the motor shaft by

hand while you read the dial.

3. Make sure that the runout

does not exceed NEMA

standards, 0.002 in (0.05

mm) maximum TIR.

4. If the indicator reads higher

than 0.002 in

(0.05 mm)TIR, loosen the four motor hold-down

bolts and relocate the motor on the motor base

register.

5. Obtain the desired position.

6. Tighten the hold-down bolts and repeat the

indicator reading.

Note: Adding or removing shims between the motor

and the discharge head helps alignment in the

vertical direction. The motor may also have to be

adjusted in the horizontal direction for alignment.

FLATNESS OF THE SEAL HOUSING

For this measurement, remove the mechanical seal if the

dial indicator stylus cannot rotate 360° on the top surface

of the seal gland.

1. Install the dial indicator as

shown, with the base 1)

Remove the lower coupling

components and attach the

base of the dial indicator to

the motor shaft.

2. Place the stylus at the top

surface of the seal gland, or

at the top surface of the seal

housing.

3. Slowly rotate the motor

shaft 360°.

4. Check that the face of the seal housing is square with

the shaft to within 0.002 in (0.05 mm) TIR.

CONCENTRICITY OF THE SEAL HOUSING

This measurement requires that you remove the

mechanical seal.

1. Install the dial indicator as

shown.

2. Rotate the motor shaft

by hand and run the

indicator in the inside-

machined surface of the

seal housing in order to

determine the concentricity.

3. If the indicator reads

higher than 0.004 in (0.10

mm) TIR, loosen the four

motor hold-down bolts and

relocate the motor on the motor base register.

4. Obtain the desired position.

5. Tighten the hold-down bolts and repeat the

indicator reading.

CONCENTRICITY OF THE HEADSHAFT

1. Reinstall the mechanical

seal if it was removed for

the flatness or concentricity

measurement.

2. Install the coupling assembly

and adjust the impeller.

3. Attach the base of the dial

indicator on the discharge

head or motor support.

4. Place the stylus on the shaft

between the top of the seal

and the bottom of the pump coupling.

5. Slowly rotate the motor shaft 360°.

6. Check that the shaft runout is within 0.004 in

(0.10 mm) TIR, or as required by specification.

7. Drill and dowel the pin in three places in order to

secure the motor to the motor base after you obtain

the required runouts.

CONCENTRICITY OF MOTOR SHAFT USING

JACKSCREWS

1. Install the dial indicator

as shown, with the base

attached to the motor

support.

2. Rotate the motor shaft by

hand while you read the

dial.

3. Make sure that the runout

does not exceed NEMA

standards, 0.002 in (0.05

mm) maximum TIR.

4. If the indicator reads higher than 0.002 in

(0.05 mm) TIR, using the jackscrews relocate the

motor on the motor base (sometimes no register).

5. Obtain the desired position.

6. Tighten the hold-down bolts (not the jackscrews)

and repeat the indicator reading.

Note: Adding or removing shims between the

motor and the discharge head helps alignment in

the vertical direction. The jackscrews are provided

to adjust the motor in the horizontal direction for

alignment.

INSTALLING THE DRIVER

When installed in a potentially explosive

environment, please ensure the motor is

properly certified.

Serious damage may result if pump is run

in the wrong direction.

NOTE: When pump is supplied with a thrust pot, do not

secure the driver to discharge head until after the

thrust pot and flexible coupling are installed.

INSTALLATION OF A HOLLOW SHAFT DRIVER

This refers to either VHS type electric motors or hollow

shaft type gear drives. A small paragraph will be devoted

to combination electric motor and right angle gear

drives.

WARNING