Xylem IMVIC R01 Model VIC Vertical Industrial Turbine Can Pumps User Manual

Page 15

15

Do not work under a heavy suspended

object unless there is a positive support

and safe guards which will protect personnel should a

hoist or sling fail.

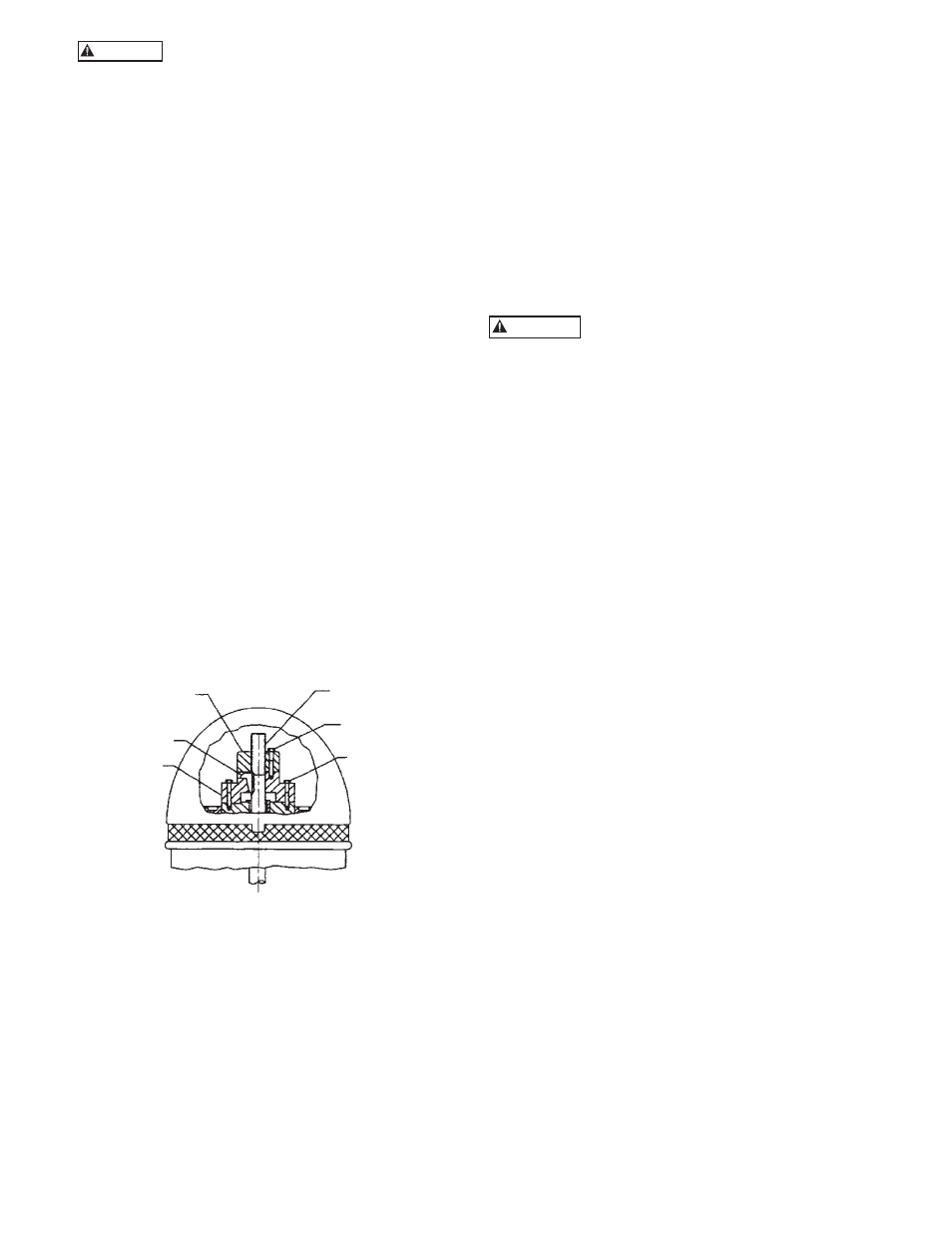

1. The driving mechanism of all hollow shaft driver is

shown on Figure 7. The head shaft (608) extends up

through the quill or hollow shaft of the driver and

is held in place by an adjusting nut (604), which not

only carries all the static and hydraulic thrust of the

impellers and shaft, but also provides the adjustment

for the impeller clearances. The head shaft is

connected to top shaft (or stub shaft) by a threaded

coupling or a rigid flange coupling.

2. Attach a sling to the lifting lugs of driver and hoist

the driver up. Inspect the mounting surface, register

and clean these surfaces thoroughly. If any burrs

are found, remove burrs with a smooth mill file,

cleaning thoroughly afterward.

3. For motor, orient the motor conduit box in the

required position. For the right angle gear, orient

the input shaft to the desired position. Align the

driver mounting holes with the mating tapped holes

on the discharge head. Lower the driver until the

registers engage and the driver rests on the discharge

head. Secure driver with capscrews provided.

4. Lubricate the driver bearings in accordance with

instructions given on lubrication plate attached to

the driver case. (Or refer to IOM of the driver)

5. After lowering and orienting the driver as explained

above, remove the drive coupling and the hold

down bolts (See Figure 16). Be sure to mark the

location of the coupling before removing it.

Figure 7

6. Lower the head shaft through the motor quill shaft

to meet the shaft coupling. Apply a thin film of oil

to head shaft threads (if non-galling material) and

screw into the shaft coupling (located above the

stuffing box). Make sure the shaft is not damaged in

any way. Tighten the joint.

7. Check that the head shaft centers inside the driver

quill shaft within 0.06” (1.5mm). If it does not,

misalignment is indicated.

8. Any head shaft misalignment with driver quill

shaft could be caused by a bent head shaft, burrs,

or foreign matter between shaft ends or any of the

mounting flanges: motor flange to discharge head

top flange, discharge head base flange to base plate

or the base plate itself could be out of level. If the

latter, shimming between it and discharge head base,

will correct it. Also, check concentricity of motor to

motor-stand (if provided) to discharge head.

9. With the motor in place and the head shaft

projecting through the motor quill shaft, make

temporary electrical connection to check the motor

rotation. (Be sure to remove the ratchet pins or balls

before checking motor rotation.) Motor must rotate

counter-clockwise when viewed from the top. See

arrow on pump name plate. If motor does not rotate

counter-clockwise, you can change the rotation by

interchanging any two leads.

Never check motor rotation with the drive

coupling in place. The bore clearance

between the drive coupling and the pump shaft O. D.

is so close that should the motor spin with this shaft

stationary, galling and locking together is very likely to

take place.

10. Install motor drive coupling. (Be sure to line up the

match mark made at step 5.) Insert the ratchet pins

if a non-reverse ratchet is used. Match the coupling

lugs with corresponding holes in motor. Tighten

hold down bolts evenly, making sure driver coupling

is properly seated in the register fit.

11. Fit gib key (730) into keyway, by filing if necessary,

to where there is a snug but sliding fit. This key

must be able to be removed by gentle leverage with

a screwdriver under it.

12. Be careful that the gib key (730) is not too high so

as to hold up the adjusting nut (604) from seating

on the drive coupling. If it is, cut off some length of

the key.

13. Install adjusting nut (604) to hand tight.

COMBINATION ENGINE AND MOTOR DRIVES

1. On combination drivers, the motor is invariably on

top with a projecting head shaft extension.

2. Follow all procedures outlined in the previous

paragraph, except that the motor must be lowered

over this extended head shaft and great care must be

taken to center it exactly so as not to bump or mis-

align the shaft while the motor is being lowered into

place.

3. There are several methods of running engines

without electric motors and vice versa, requiring

simple adjustment to the combination drive, but

they are too numerous to mention here and can be

obtained from the gear manufacturers instructions

included with the shipment.

HEAD SHAFT (608)

CAPSCREW (760)

ADJUSTING NUT

HOLD

DOWN BOLT

(604) ADJUSTING

NUT

(730) GIB KEY

DRIVE

COUPLING

CAUTION

WARNING