Xylem IMVIC R01 Model VIC Vertical Industrial Turbine Can Pumps User Manual

Page 18

18

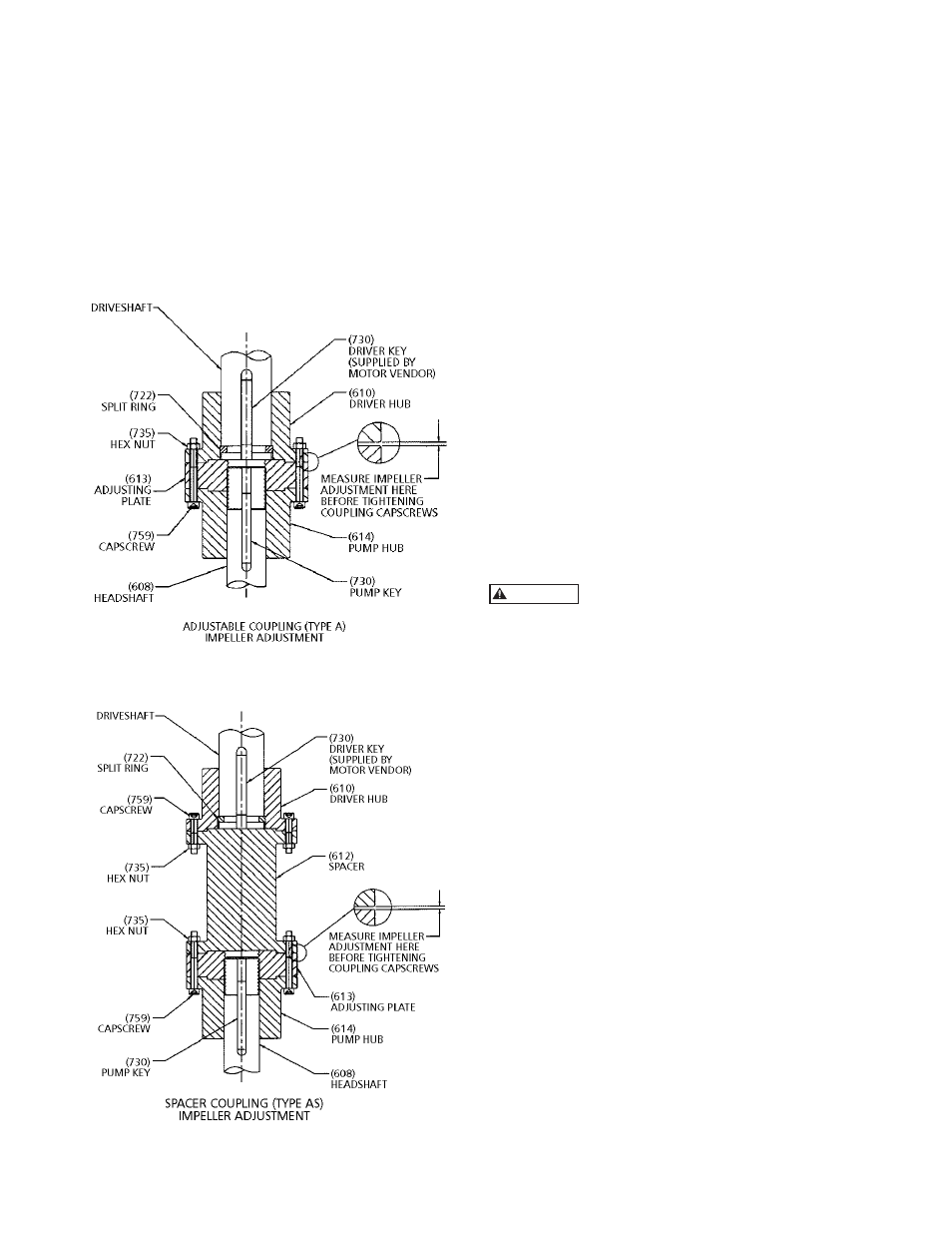

2. After impeller adjustment, align adjusting plate (613)

with the pump hub (614), and tightly draw coupling

flanges together with capscrews (759) and nuts

(735). (See figure 9 and 10).

3. Check shaft run out with dial indicator. For

mechanical seal installation, the run out should be

0.005 or less.

4. Set seal after impeller adjustment. Securely tighten

all set screws in the collar. Remove the spacer

between the gland plate and collar. Retain spacer for

future resetting of seal.

NOTE: When impellers are reset, the seal must also be

reset.

Figure 11

Figure 12

ENCLOSED IMPELLERS

For enclosed impellers obtain the clearance between the

adjusting plate and driver hub or spacer as specified on

the outline drawing. See Figure 11 or 12.

INSTALLING THE GREASE LUBRICATED THRUST POT

This type of thrust pot and the motor stand are

assembled on the discharge head by the factory. This

thrust pot is designed to be used with NEMA Vertical

C-face motors. The motor shaft and the pump shaft have

to be coupled with flexible coupling.

INSTALLATION:

1. Install both coupling halves prior to mounting

the motor. Refer to the coupling manufacturer’s

instructions.

2. Using the lifting lugs on the motor, carefully lower

the motor onto the motor stand of the thrust pot

(See Figure 13) and align the bolt holes.

3. Install the bolts finger tight.

4. Make temporary electrical connections according

to tagged leads or diagram attached to the motor.

Motor must rotate counterclockwise when viewed

from the top. See arrow on pump name plate. If

motor does not rotate counterclockwise, you can

change the rotation by interchanging any two leads.

Before beginning any alignment procedure,

make sure driver power is locked out.

Failure to lock out driver power will result in serious

physical injury.

ALIGNMENT OF FLEXIBLE COUPLING:

Alignment of the pump and motor is extreme importance

for trouble-free mechanical operation. Straight edge

alignment by an experienced installer proves adequate for

most installations.

1. Check for coupling alignment by laying a straight

edge across both coupling rims at four points 90º

apart.

2. Move motor until straight edge rests evenly at each

position. Repeat procedure until correct alignment is

achieved.

3. Install flexible sleeve between the hubs per the

manufacture’s instructions.

4. Tighten all motor bolts.

NOTE: Be sure the relief fitting (#11 in Figure 13) is

clear of paint or any other obstructive material.

Otherwise it will cause premature failure of the

thrust pot and is not covered under warranty.

WARNING