Xylem AC8584C Series HSCS Base Mounted Centrifugal Pumps User Manual

Page 8

8

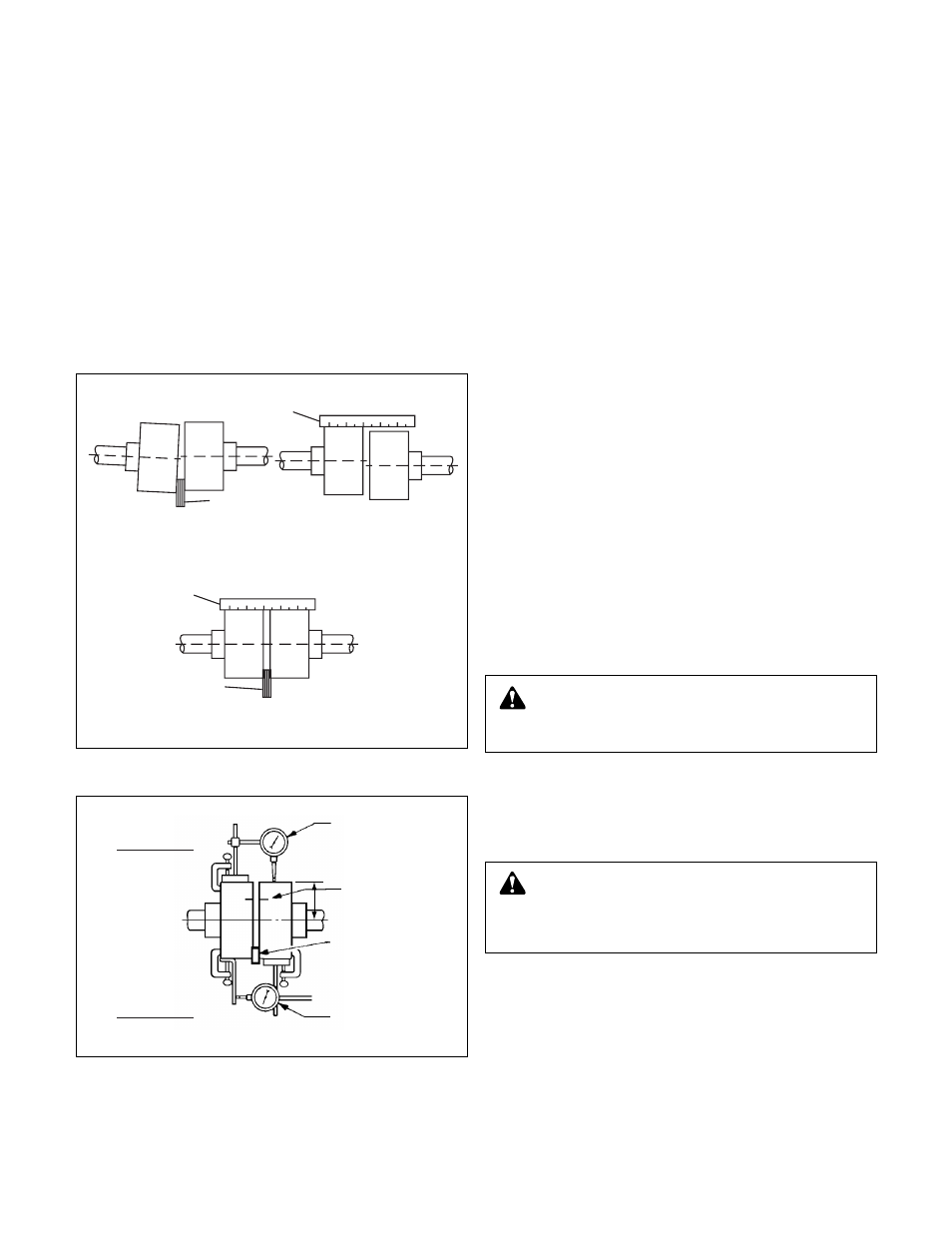

Method 1 – Using Straight Edge & T

aper Gauges

or Feelers

(See Figur

e 6A)

Proceed with this method only if satisfied that face and out-

side diameters of the coupling halves are square and concen-

tric with the coupling borers. If this condition does not exist or

elastomeric couplings do not make this method convenient,

use Method 2.

1. Check angular misalignment using a micrometer or caliper.

Measure from the outside of one flange to the outside of

the opposite flange at four points 90° apart. DO NOT

ROTATE COUPLER. Misalignment up to

1

/

64

" per inch of

coupler radius is permissible.

2. At four points 90° apart (DO NOT ROTATE COUPLER),

measure the parallel coupler misalignment by laying a

straight edge across one coupler half and measuring the

gap between the straight edge and opposite coupler half.

Up to a

1

/

64

" gap is permissible.

Method 2 – Using Dial Indicators (Figur

e 6B)

a. Make sure each hub is secured to its respective shaft and

that all connecting and/or spacing elements are removed at

this time.

b. The gap between the coupling hubs is set by the manufac-

turer before the units are shipped. However, this dimension

should be checked. (Refer to the coupling manufacturer’s

specifications supplied with the unit.)

c. Scribe index lines on coupling halves as shown in Figure

6B.

d. Mount dial indicator on one hub as shown for parallel align-

ment. Set dial to zero.

e. Turn both coupling halves so that index lines remain

matched. Observe dial reading to see whether driver needs

adjustment (See paragraph i below).

f. Mount dial indicator on one hub as shown for angular align-

ment. Set dial to zero.

g. Turn both coupling halves so that index lines remain

matched. Observe dial reading to see whether driver needs

adjustment (See paragraph i below).

h. Assemble coupling. Tighten all bolts and set screw(s). It

may be necessary to repeat steps c through f for a final

check.

i. For single element couplings, a satisfactory parallel mis-

alignment is .004"T.I.R., while a satisfactory angular mis-

alignment is .004"T.I.R. per inch of radius R (See Figure 6B).

Final Alignment

Final alignment cannot be accomplished until the pump has

been operated initially for a sufficient length of time to attain

operating temperature. When normal operating temperature

has been attained, secure the pump to re-check alignment

and compensate for temperature accordingly. See Alignment

Section.

OPTIONAL Alignment Pr

ocedure

If desir

ed, the pump and motor feet can be doweled to the

base after final alignment is complete. This should not be

done until the unit has been run for a sufficient length of time

and alignment is within the tolerance. See Doweling Section.

NOTE: Pump may have been doweled to base at factory

.

STRAIGHT EDGE

FEELER GAGE

FEELER GAGE

ANGULAR ALIGNMENT

PARALLEL ALIGNMENT

CORRECT ALIGNMENT

STRAIGHT EDGE

INCORRECT ALIGNMENT

FIGURE 6A – CHECKING ALIGNMENT (METHOD 1)

FIGURE 6B – CHECKING ALIGNMENT (METHOD 2)

DIAL

INDICATOR

INDEX LINE

R

RESILIENT

SEPARATOR

DIAL

INDICATOR

PARALLEL

ALIGNMENT

ANGULAR

ALIGNMENT

WARNING: Rotating Components Hazard

Do not operate pump without all guar

ds in place.

Failure to follow these instructions could result in serious

personal injury or death and property damage.

CAUTION:

Extreme Temperature and/or

Flying Debris Hazard

Eye pr

otection and gloves required. Failure to follow these

instructions could result in property damage and/or moder-

ate personal injury.