Xylem AC8584C Series HSCS Base Mounted Centrifugal Pumps User Manual

Page 17

1

ÇÊ

A Mobile Oil, DTE Medium, or equal, meeting the following

Ê

specification will provide satisfactory lubrication. SImilar oils

Ê

can be furnished by all major oil companies. It is the responsi-

Ê

bility of the oil vendor to supply a suitable lubricant.

Ê

(1)

Saybolt viscosity at 100ºF . . . . . . . . . . 215 SSU-240 SSU

Ê

(2)

Saybolt viscosity at 210ºF . . . . . . . . . . . . . . . . . . . 49SSU

Ê

(3)

Viscosity index, minimum. . . . . . . . . . . . . . . . . . . . . . . . 95

Ê

(4)

API gravity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-33

Ê

(5)

Pour point, maximum . . . . . . . . . . . . . . . . . . . . . . . . +20ºF

Ê

(6)

Flash point, minimum . . . . . . . . . . . . . . . . . . . . . . . . 400ºF

Ê

(7)

Additives . . . . . . . . . . . . . . . . . Rust & Oxidation inhibitors

Ê

(8)

ISO viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Ê

NOTE: Oils fr

om different suppliers should not be mixed.

Ê

Engine oils are not recommended.

Ê

The oil should be a non-foaming, well refined, good grade,

Ê

straight cut, filtered mineral oil. It must be free from water,

Ê

sediment, resin, soaps, acid and fillers of any kind.

Ê

In installations with moderate temperature changes, low

Ê

humidity, and a clean atmosphere, the oil should be changed

Ê

after approximately 1000 hours of operation. The oil should be

Ê

inspected at this stime to determine the operating period

Ê

before the next oil change. Oil change periods may be

Ê

increased up to 2000-4000 hours based on an 8000 hour year.

Ê

Check the oil frequently for moister, dirt, or signs of “break-

Ê

down,” especially during the fist 1000 hours.

Ê

4. Mechanical Seals

a.

Mechanical seals are precision products and should be

Ê

treated with care. Use special care when handling seals.

Ê

Clean parts are essential to prevent scratching the finely

Ê

lapped sealing faces. Even light scratches on these faces

Ê

could result in leaky seals.

Ê

b. Normally, mechanical seals require no adjustment or main-

Ê

tenance, except routine replacement of worn, or broken

Ê

parts.

Ê

c. A mechanical seal which has been used should not be put

Ê

back into service until sealing faces have been replaced or

Ê

relapped. (Relapping is generally economical only in seals

Ê

two inches in size and above.)

Ê

Four important rules which should always be followed for

Ê

optimum seal life are:

Ê

1.

Keep the seal faces clean as possible.

Ê

2.

Keep the seal as cool as possible.

Ê

3.

Assure that the seal always has proper lubrication.

Ê

4.

If seal is lubricated with filtered fluid, clean filter

Ê

frequently.

Ê

5. Packing Seal

When a pump with packing is first started it is advisable to

Ê

have the packing slightly loose without causing an air leak. As

Ê

the pump runs in, gradually tighten the gland bolts evenly. The

Ê

gland should never be drawn to the point where packing is

Ê

compressed too tightly and no leakage occurs. This will cause

Ê

the packing to burn, score the shaft sleeve and prevent liquid

Ê

from circulating through the stuffing box cooling the package.

Ê

NOTE: Eccentric run-out of the shaft or sleeve thr

ough the

Ê

packing could result in excessive leakage that cannot be com-

Ê

pensated for. Correction of this defect requires shaft and/or

Ê

sleeve replacement. Packing should be checked frequently

Ê

and replaced as service indicates. Six months might be a rea-

Ê

sonable expected life, depending on the operating conditions.

Ê

6. Cleaning Without Dismantling Pump

A short section of pipe so designed that it can be r

eadily

Ê

dropped out of the line can be installed adjacent to the suction

Ê

flange. With this arrangement, any matter clogging the

Ê

impeller is accessible by removing the pipe section.

Ê

If the pump cannot be freed of clogging after the above

Ê

methods have been tried, dismantle the unit as previously

Ê

described to locate the trouble.

CAUTION:

Do not over oil; this causes the bearings to run hot.

Ê

The maximum desirable bearing housing operating

Ê

temperature for all ball bearings is 180º)F. Should the

Ê

temperature of the bearing frame exceed 180º)F (measured

Ê

by thermometer) shut down pump to determine the cause.

Ê

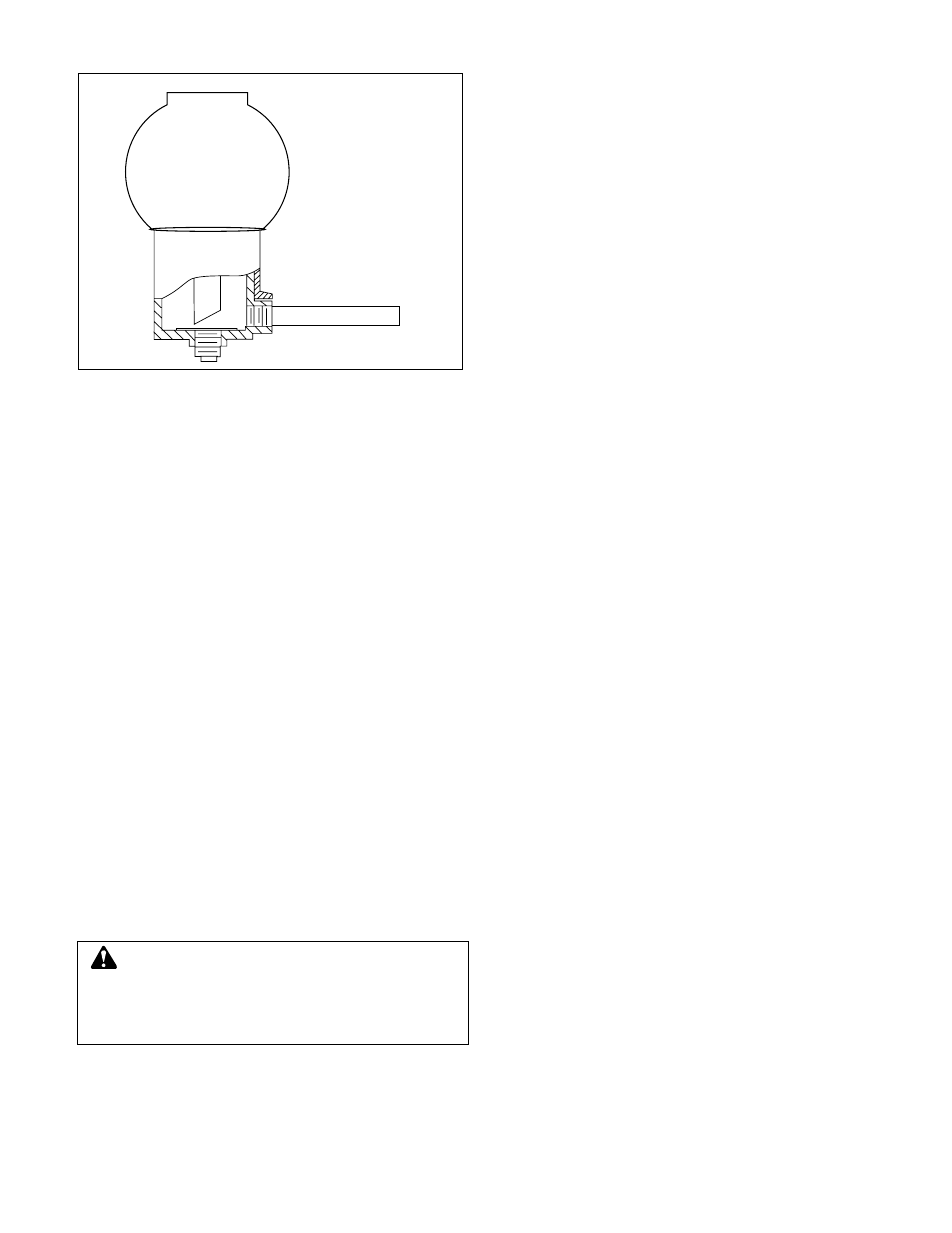

FIGURE 11 – TRICO OILER