Xylem AC8584C Series HSCS Base Mounted Centrifugal Pumps User Manual

Page 28

2

nÊ

To install the oil ring, place the oil ring in the bearing housing

Ê

directly under the pipe plug hole. Run a wire through the pipe

Ê

plug hole, around the oil ring and back through the pipe plug

Ê

hole once again. Tie the wire to a metal washer (being a larger

Ê

diameter then the hole) causing the oil ring to become tight

Ê

against the inside top of the bearing housing. Then assemble

Ê

the bearing housing over the bearing. Untie the wire and the

Ê

oil ring will drop down onto the shaft. Check the position of

Ê

the oil ring through the pipe plug hole at the top of the bearing

Ê

housing. The oil ring must be resting on the shaft for correct

Ê

operation. A screwdriver can be used to correct the oil ring

Ê

position, if required.

Ê

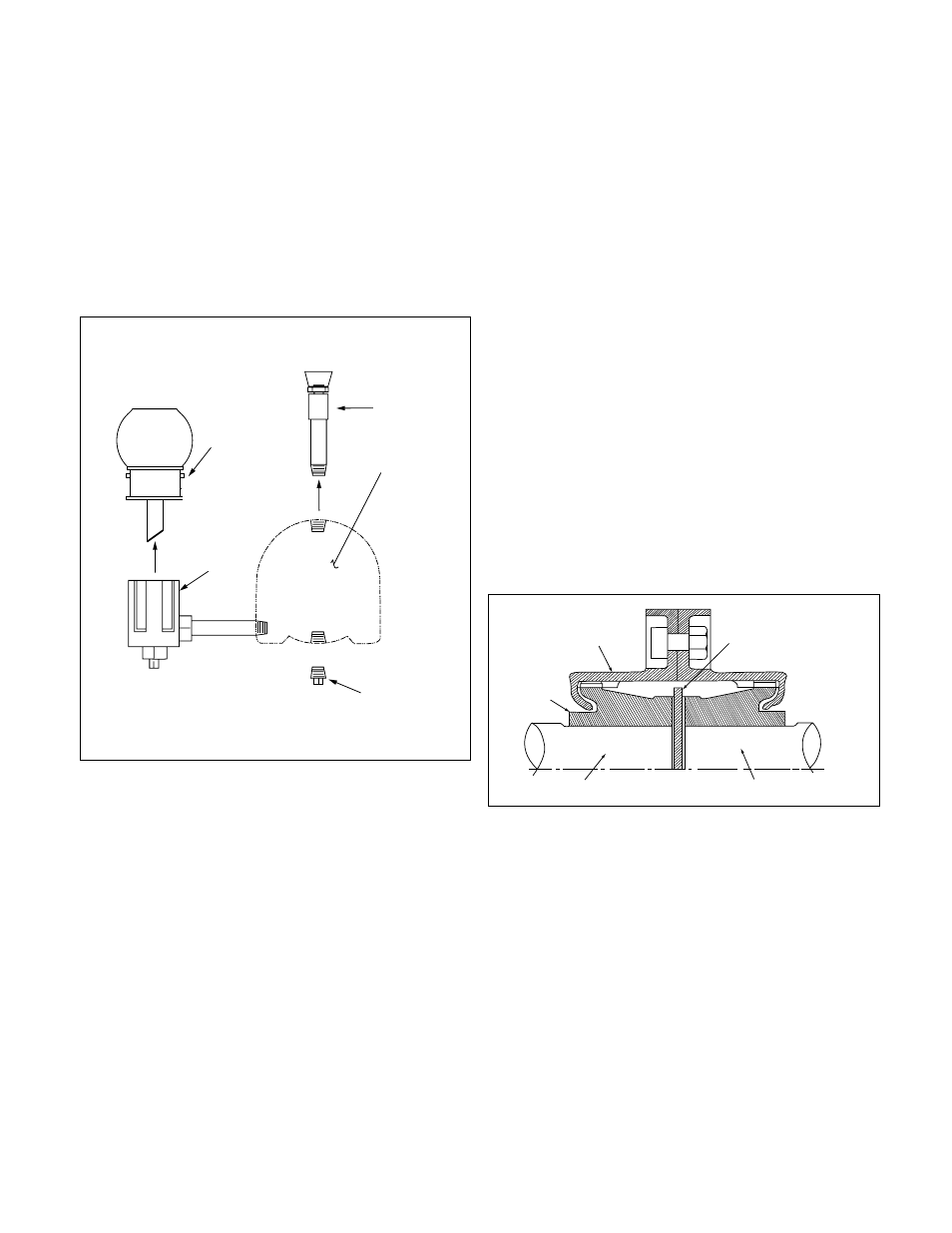

The following steps describe how to change the oil for oil

Ê

lubricated bearings. Figure 27 shows a typical oiler assembly.

Ê

1. Remove the vent assembly from the top of the bearing

Ê

housing.

Ê

2. Remove the pipe plug from the bottom of the bearing

Ê

housing.

Ê

3. Unscrew the reservoir and remove.

Ê

4. Flush the oiler and bearing housing with a light grade of

Ê

oil. Flush until all foreign particles have been removed.

Ê

5. Screw the pipe plug and vent assembly back into place.

Ê

6. Fill the reservoir with a good grade of filtered mineral oil.

Ê

Refer to oil lubrication instructions given previously in this

Ê

manual for type of oil.

NOTE: Y

ou must fill through Trico reservoir.

Ê

7. Place thumb over reservoir spout, invert and place reser-

Ê

voir on lower casting while removing thumb. Allow reser-

Ê

voir to empty, filling the bearing housing. Several fillings

Ê

of the reservoir may be required before the actual level is

Ê

reached, no more oil will run out of the reservoir.

Ê

8. When reservoir stays full, screw reservoir back into lower

Ê

casting.

Ê

Aperiodic filling of the reservoir is required. When the oil

Ê

becomes dirty, repeat steps 1 through 8.

Ê

LIMITED END FLOA

T COUPLING

For units with drivers having sleeve bearings the coupling

Ê

halves are set to limited total shaft axial movement to less

Ê

than one-half of the motor rotor assembly end float. This is

Ê

accomplished by inserting a phenolic disc, or equivalent, of a

Ê

specified thickness between the motor and pump shaft (See

Ê

Figure 28).

Ê

Most HSCS pumps installations use the all metal, gear type

Ê

coupling. Where limited end float gear type couplings are

Ê

used, the coupling hubs are slip-fit onto the pump and motor

Ê

shafts. After installation of the coupling covers and hubs; with

Ê

the motor set on its Magnetic Center, butt the pump and

Ê

motor shafts with the phenolic disc inserted between them.

Ê

(The pump thrust bearing limits end float towards the motor.)

Ê

The thrust bearing of the pump is large enough to carry any

Ê

magnetic thrust developed by the motor when aligned prop

Ê

erly.

Ê

Once the above instructions have been followed out com-

Ê

pletely, the

Alignment Pr

ocedures

starting on page 6 should

Ê

be followed.

Ê

FIGURE 28 – LIMITED END FLOA

T

COUPLING ARRANGEMENT

COVER

HUB

MOTOR SHAFT

PUMP SHAFT

PHENOLIC DISC

FIGURE 27 – OILER ASSEMBLY

RESERVOIR

LOWER

CASTING

VENT

ASSEMBLY

BEARING

HOUSING

PIPE

PLUG