Operating instructions, Service instructions – Bell & Gossett A05767B Sediment Removal Separator SRS User Manual

Page 2

OPERATING INSTRUCTIONS

1. The SRS separates sediment from the system by centrifu-

gal force. Heavier than water sediment particles are thrown

against the inner walls of the SRS and move down the walls

to the sump in the bottom of the SRS where it collects.

IMPORTANT: The SRS is designed only for the removal of

undissolved, inorganic, heavier than water sediment/solids

that enter through cooling towers, make-up water or via sys-

tem installation. The SRS is not intended for removal of dis-

solved sediment or organic material like algae.

2. Collected sediment must be periodically blown down

(removed) from the 1" NPT sump connection on the bottom

of the SRS. If excessive amounts of sediment are allowed

to collect without being periodically removed, sediment will

start to pass through the SRS and not be removed. Purging

(blowdown) of the sump can be accomplished manually but

a much preferred method is by the the use of an automatic

valve and adjustable timer system. The timer cycle and the

length of time the purge (blowdown) valve is open will vary

depending on the amount of sediment in the system.

IMPORTANT: Failure to adequately purge the SRS may result

in a buildup of sediment in the sump which may clog and pre-

vent discharge of sediment.

WARNING: The SRS is not designed for fresh

water service. Excessive corrosion of steel construc-

tion will occur. Do not use in systems with fresh water

being added unless corrosion inhibitors are present.

Failure to follow these instructions could result in serious

personal injury or death and property damage.

SERVICE INSTRUCTIONS

1. The SRS must be inspected periodically for signs of corro-

sion. If corrosion exceeds .050" the SRS must be replaced.

WARNING: Excessive corrosion will cause the

SRS to leak or rupture. Periodic inspections must

be made to check for corrosion. Failure to follow these

instructions could result in serious personal injury or

death and property damage.

2. There are no moving parts or strainers in the SRS that re-

quire service.

3. Purge valves and associated equipment may require ser-

vice. Refer to the instruction manuals supplied with these

devices for service requirements.

WARNING: The SRS is an ASME Code Section

VIII Div. 1 designed and constructed pressure vessel.

Welding by uncertified welders will void the ASME certi-

fication and result in an unsafe condition. Failure to follow

these instructions could result in serious personal injury

or death and property damage.

3. The SRS needs to be mounted sufficiently high off the floor

to allow blow down piping to be attached.

4. The SRS should be located near a drain to facilitate the

removal of collected sediment. If an automated blowdown/

purge valve is used, air or electricity will have to be provided

to this location. For installation of blowdown components,

follow the instructions provided with this equipment.

IMPORTANT: Purge/blowdown valves selected must be

designed for sediment service or else clogging, seat wear or

damage will occur resulting in valve leakage.

5. If the air separation feature of the SRS is to be utilized an

automatic air vent, such as a Bell & Gossett 107A Air Vent,

must be installed in the SRS top connection. The SRS can

also be piped to a standard compression tank. Refer to Bell

& Gossett Instruction Manual S10300 for installation

instructions.

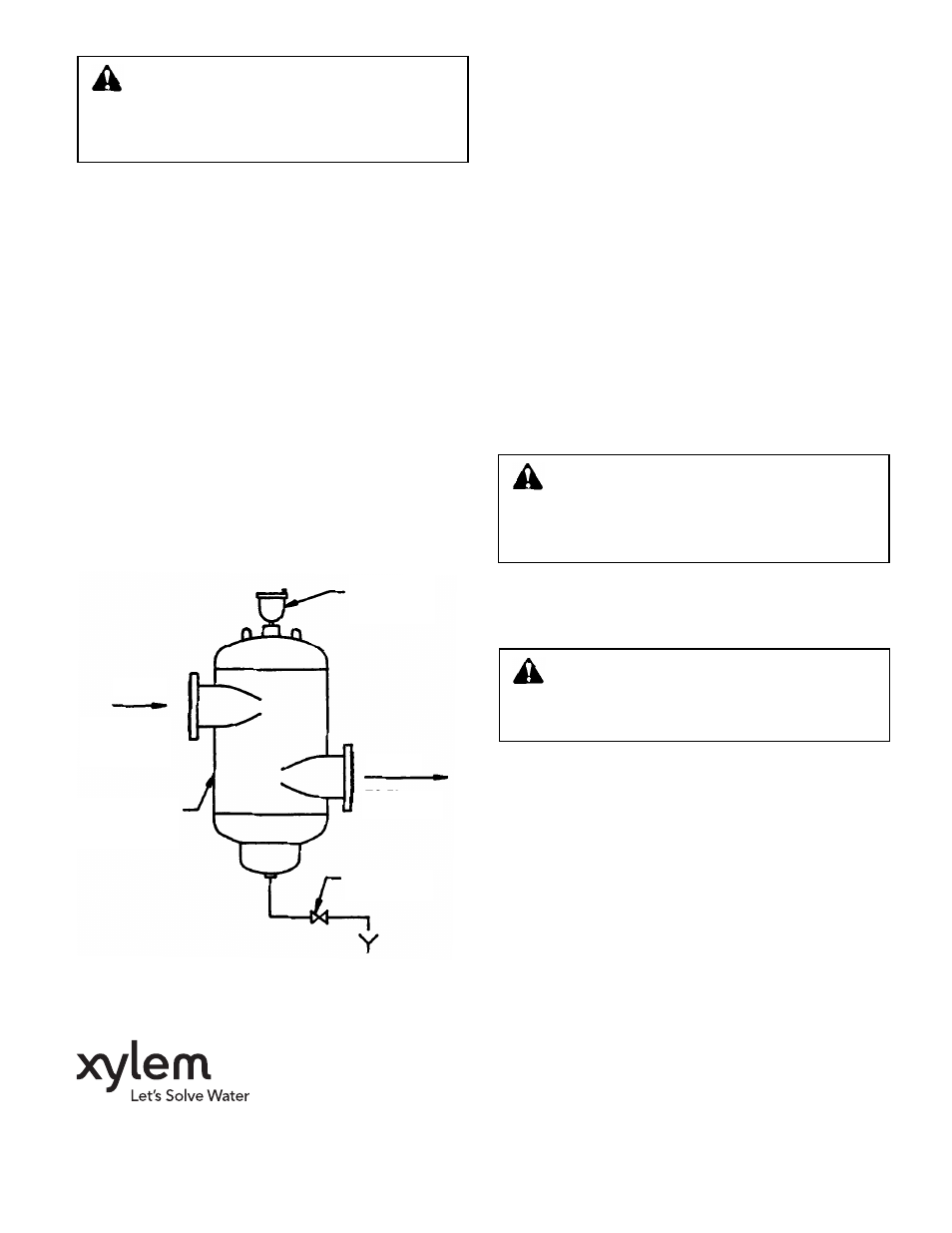

6. Figure 1 shows a typical installation with some of the

optional equipment that can be utilized with the SRS.

OUTLET

TO PUMP

SUCTION

BLOW DOWN

VALVE

INLET

FROM BOILER

CHILLER OR

CONVERTER

B&G SEDIMENT

REMOVAL

SEPARATOR

AUTOMATIC

AIR VENT

107A

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. A05767B May 2012