Operating sequence – Bell & Gossett 210668B Z-4M User Manual

Page 2

• The sensor should be installed at an elevation above the

ground that will prevent accidental damage or tampering.

• Connect 18 AWG or similar wire to the two terminals pro-

vided in the enclosure and run the wires from the sensor to

the control as shown in Figure 2. Do not run the wires paral-

lel to telephone or power cables. If the sensor wires are

located in an area with strong sources of electromagnetic

interference (EMI), shielded cable or twisted pair should be

used or the wires can be run in a grounded metal conduit. If

using shielded cable, the shield wire should be connected

to the Com Sen terminal on the control and not to earth

ground.

• Replace the front cover of the sensor enclosure.

Water Temperature Sensor

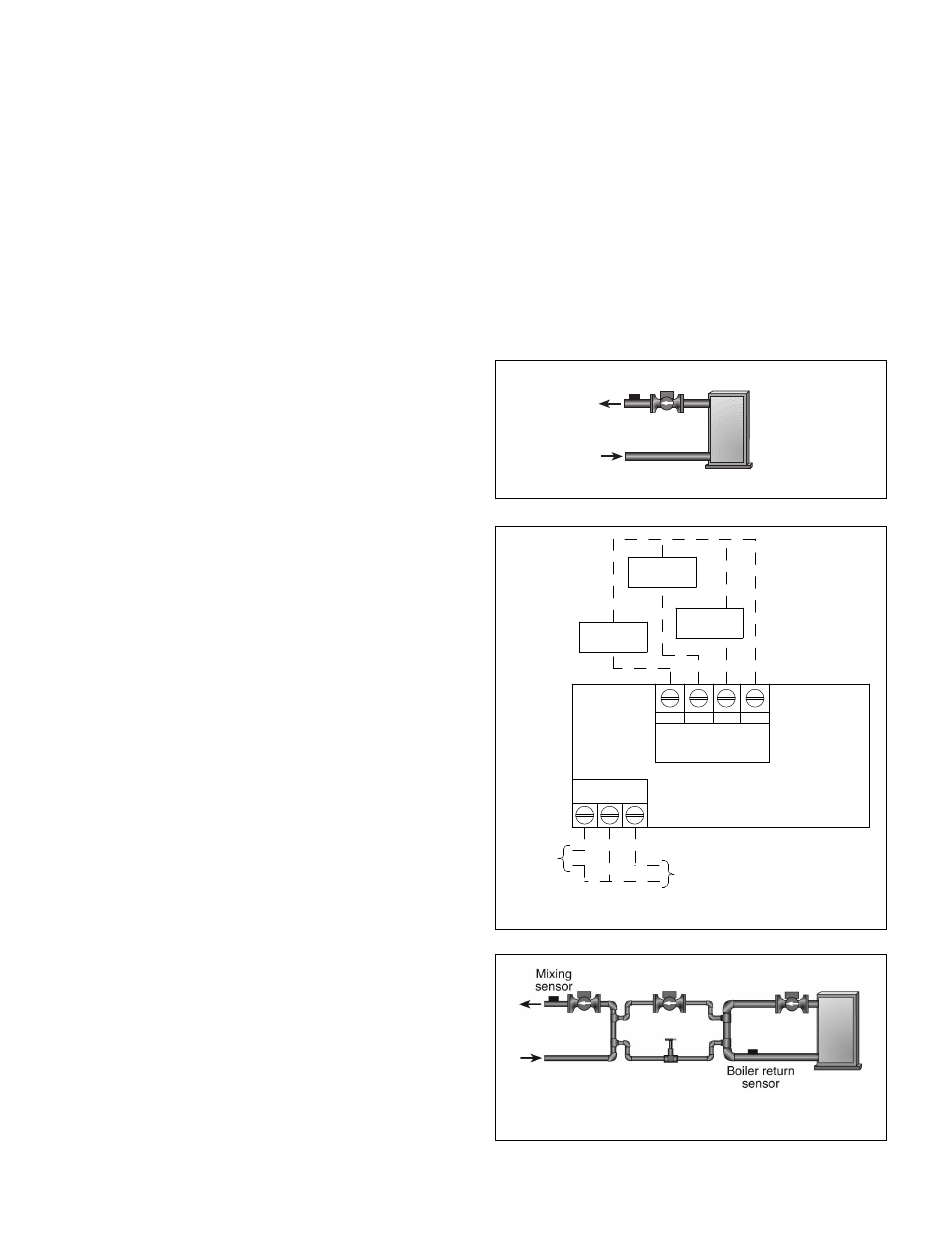

• Water temperature sensors should be located as shown in

Figures 1 (boiler reset) & 3 (mix reset).

• Sensor wiring is per Figure 2.

• The Water Temperature Sensor can be strapped directly to

the pipe using the cable tie provided. Insulation should be

placed around the sensor to reduce the effect of air currents

on the sensor measurement.

• The Water Temperature Sensor should be placed down-

stream of a pump or after an elbow or similar fitting. This is

especially important if large diameter pipes are used as the

thermal stratification within the pipe can result in erroneous

sensor readings. Proper sensor location requires that the

fluid is thoroughly mixed within the pipe before it reaches

the sensor.

OPERATING SEQUENCE

Boiler Reset Control

The Boiler Reset Control operates a single on / off heat source

to control the supply water temperature to a hydronic system.

The supply water temperature is based on the current outdoor

air temperature and the Characterized Heating Curve settings.

Outdoor Reset: The controller calculates a supply tempera-

ture based on the current outdoor air temperature and the

Characterized Heating Curve settings. The burner on the boiler

is then cycled to maintain the water temperature required

based on the heating curve.

Warm Weather Shutdown: When the outdoor air temperature

rises above the WWSD setting, the controller turns on the

WWSD segment in the display. When the control is in Warm

Weather Shut Down, the Boiler Demand pointer is displayed, if

there is a demand. However, the control does not operate the

heating system to satisfy this demand.

Mix Reset Control

The Mix Reset Control uses a variable speed injection pump

to control the supply water temperature to a hydronic system.

The supply water temperature is based on either the current

outdoor temperature, or a fixed setpoint.

Outdoor Reset: The controller calculates a mixing supply

temperature based on the current outdoor air temperature and

the Characterized Heating Curve settings.

Variable Speed Injection: circulator is connected to the con-

troller. The controller increases or decreases the power output

to a standard wet rotor circulator when there is a mixing

demand. The circulator speed varies to maintain the correct

mixed supply water temperature at the mix sensor. A visual

indication of the current variable speed output is displayed in

the LCD in the form of a horizontal bar graph.

Boiler Protection (BOIL MIN): The controller is capable of

providing boiler protection from cold mixing system return

water temperatures. If the boiler sensor temperature is cooler

than the BOIL MIN setting while the boiler is firing, the con-

troller reduces the output to the variable speed injection

pump. This limits the amount of cool return water to the boiler,

and allows the boiler temperature to recover.

Exercise: The controller has a built-in exercising function. If

the pump has not been operated at least once every 3 days,

the control turns on the output for 10 seconds. This minimizes

the possibility of the pump seizing during a long period of

inactivity.

Warm Weather Shutdown (WWSD)

When the outdoor air temperature rises above the WWSD set-

ting, the controller turns on the WWSD segment in the display.

When the control is in Warm Weather Shut Down, the Mixing

Demand pointer is displayed, if there is a demand. However,

the control does not operate the heating system to satisfy this

demand.

Boiler supply

sensor

BOIL OUT

SUP COM

Boiler Temp.

Sensor

Sensor

Temp. Sensor

Outdoor Temp.

Mix Supply

SYS/

BLR.

N

INJ/

MIX

120 VAC

To system

pump (if

applicable)

1/3 max.

HP*

To

injector

pump (if

applicable)

1.1A max.

Figure 1: Sensor Location for Boiler Reset

Figure 2: Sensor and Mix Pump Wiring

Figure 3: Pump Terminology and Sensor Location

on systems using Mix or Injection Pump

*Do not exceed the maximum combined load.