Pam8610, Application information – Diodes PAM8610 User Manual

Page 10

PAM8610

Document number: DSxxxxx Rev. 1 - 2

10 of 15

June 2013

© Diodes Incorporated

PAM8610

A Product Line of

Diodes Incorporated

Application Information

(cont.)

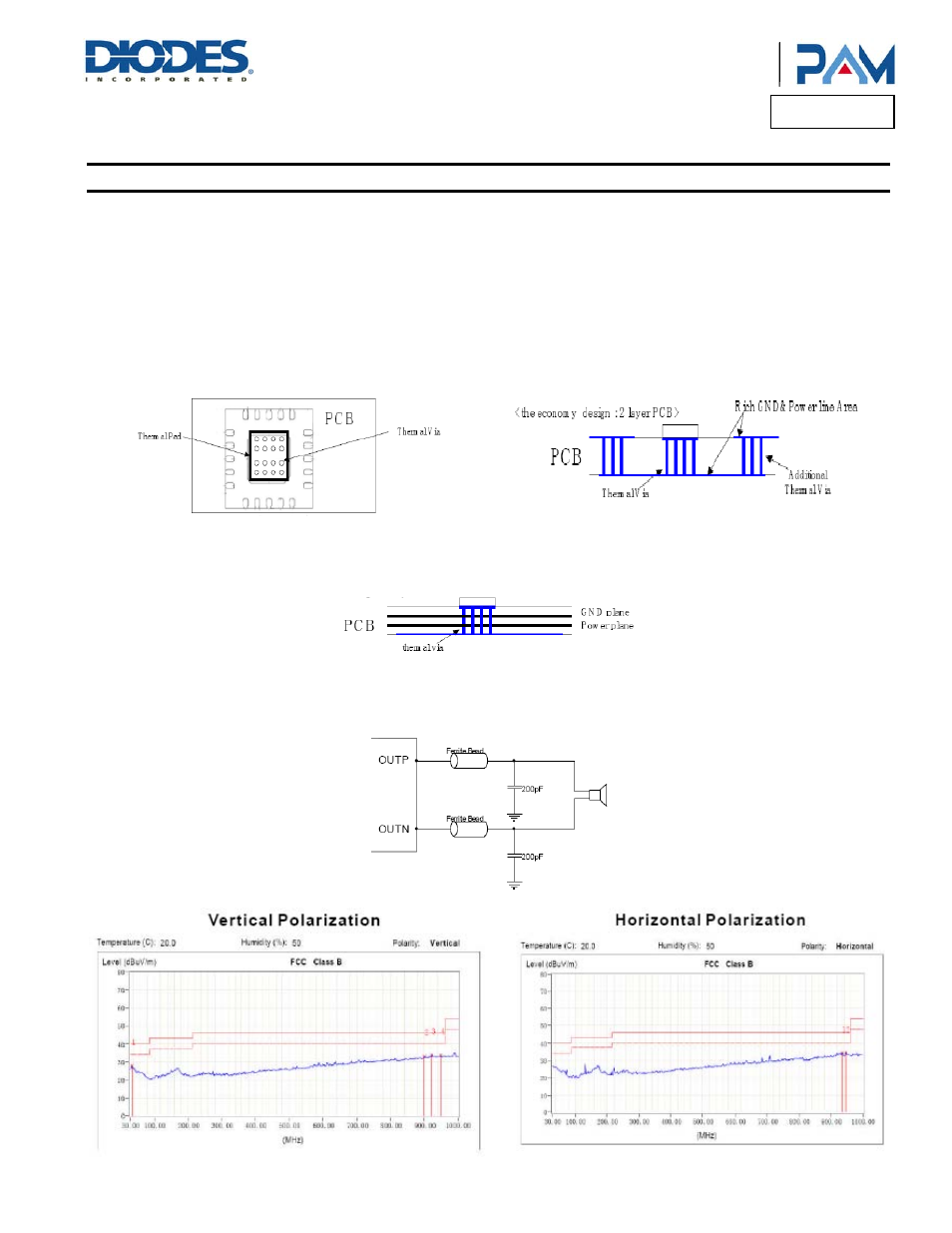

Heat Dissipation in PCB Design

Generally, class-D amplifiers are high efficiency and need no heat sink. For high power ones that has high dissipation power, the heat sink may

also not necessary if the PCB is carefully designed to achieve good heat by the PCB itself.

Dual-Side PCB

To achieve good heat, the PCB’s copper plate should be thicker than 0.035mm and both sides of the PCB should be utilized for heat sink.

The thermal pad on the bottom of the device should be soldered to the plate of the PCB, and via holes, usually 9 to 16, should be drilled in the

PCB area under the device and deposited copper on the vias should be thick enough so that the heat can be dissipated to the other side of the

plate. There should be no insulation mask on the other side of the copper plate. It is better to drill more vias around the device if possible.

4-Layer PCB

If it is 4-layer PCB, the two middle layers of grounding and power can be employed for heat dissipation, isolating them into serval islands to avoid

short between ground and power.

Consideration for EMI

Filters are not required if the traces from the amplifier to the speakers are short (<20cm). But most applications require a ferrite bead filter as

shown in below figure. The ferrite bead filter reduces EMI of around 1MHz and higher to meet the FCC and CE's requirements. It is

recommended to use a ferrite bead with very low impedances at low f requenc ies and high impedance at high frequencies (above 1MHz).

The EMI characteristics are as follows after employing the ferrite bead.