Analytical Industries GPR-2500 Series Oxygen Transmitter User Manual

Page 12

12

¾ Pressure & Flow: As described above.

¾ Moisture & Particulates: Prevent water and/or particulates from entering the sample system. They can clog the

tubing and damage the optional components such as pumps, scrubbers or sensors. Installation of a suitable

coalescing or particulate filter is required to remove condensation, moisture and/or particulates from the

sample gas to prevent erroneous analysis readings and damage to the sensor or optional components. Consult

the factory for recommendations concerning the proper selection and installation of components.

¾ Contaminants: A gas scrubber and flow indicator with integral metering valve are required upstream of the

transmitter to remove interfering gases such as oxides of sulfur and nitrogen or hydrogen sulfide that can

produce false readings and reduce the expected life of the sensor. Installation of a suitable scrubber is required

to remove the contaminant from the sample gas to prevent erroneous analysis readings and damage to the

sensor or optional components. Consult the factory for recommendations concerning the proper selection and

installation of components.

¾ Gas connections: Inlet and outlet vent gas lines require 1/8” diameter tubing preferably metal.

¾ Power connection: Locate a source of AC power to meet area classification and to plug in the charging adapter.

¾ Zero calibration (required only for very low percentage range measurements).

¾ Span calibration – Users are responsible for certified span gas cylinder, regulator and flow control valve.

Mounting the Transmitter:

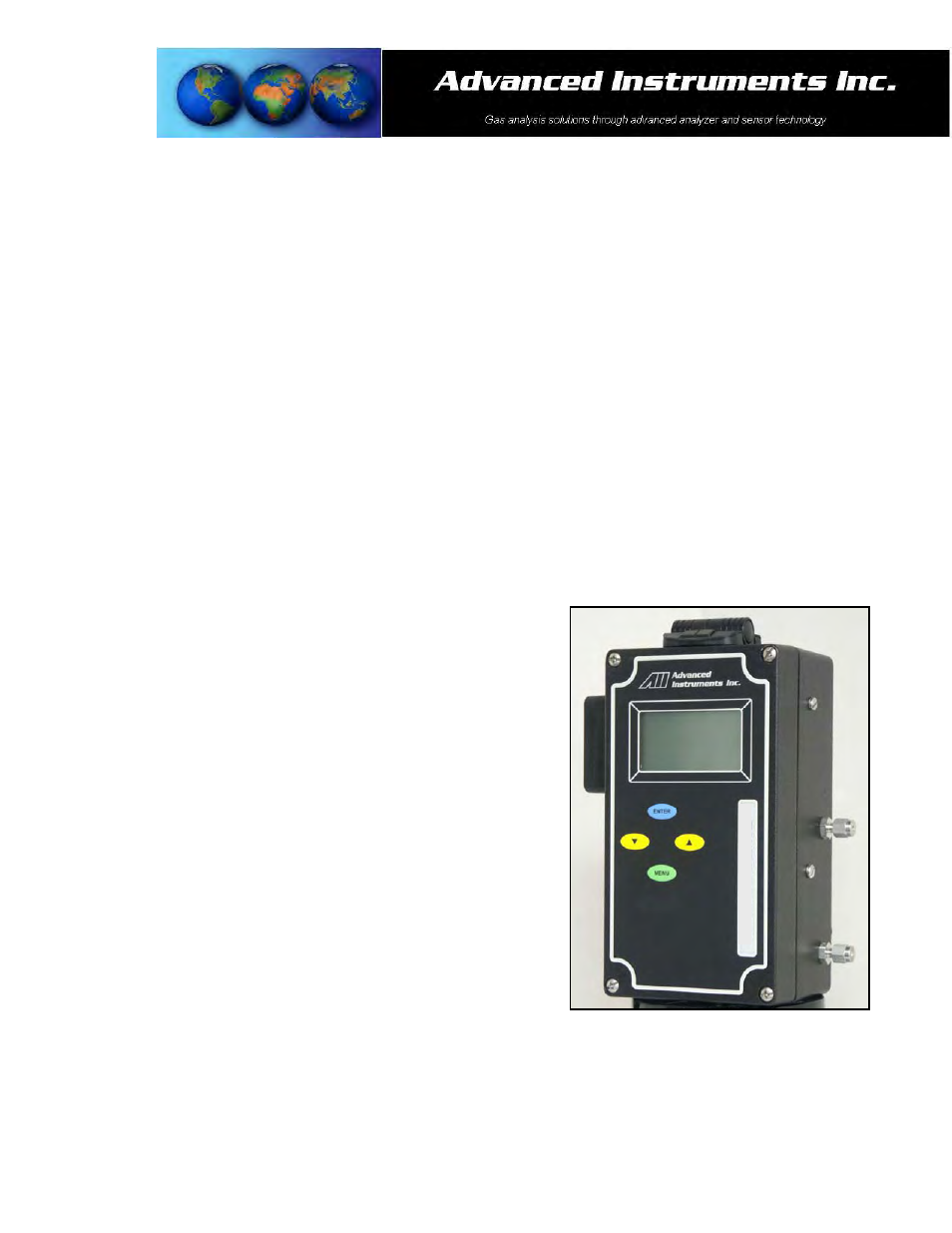

The GPR-2500/2500MO enclosure is 4”Wx9”Hx3”D configuration is

designed to be mounted directly to any flat vertical surface, wall or

bulkhead plate with the appropriate screws. To facilitate servicing

the interior of the transmitters, position it approximately 5 feet off

the floor.

1. Remove the four (4) screws securing the top section of the

enclosure, set them aside for reinstallation and raise the hinged

top section 180º until it locks in place.

2. Locate the mounting holes cast into the bottom section of the

enclosure and the black sensor. Orient the enclosure by locating

the sensor at six (6) o’clock.

3. Secure the bottom section of the enclosure to a vertical surface

approximately 5 feet from the floor or a level accessible to

service personnel. This requires the user to supply four (4)

additional proper size screws and anchors.

4. Caution: Do not remove or discard the gaskets from either the

enclosure or junction box. Failure to reinstall either gasket will

void the NEMA 4 rating and RFI protection.

5. The transmitters design provides protection from RFI that is

maintained by leaving specific mating areas of the enclosure unpainted to maintain conductivity the gasket, top

and bottom sections of the enclosure. These unpainted areas are protected by gaskets and contribute to

maintaining the NEMA 4 rating. Do not paint these areas. Painting will negate the RFI protection.

6. As described below the power connection is made through the junction box on the left side of the enclosure.