Q-tech, Qt90 series – Q-Tech QT90 User Manual

Page 4

4

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-tech.com

QT90 SERIES

HIGH-RELIABILITY MINIATURE CLOCK OSCILLATORS

1.8 to 5.0Vdc - 15kHz to 160MHz

Q-TECH

CORPORATION

QT9 0 (Revision H, January 2011) (ECO #10088)

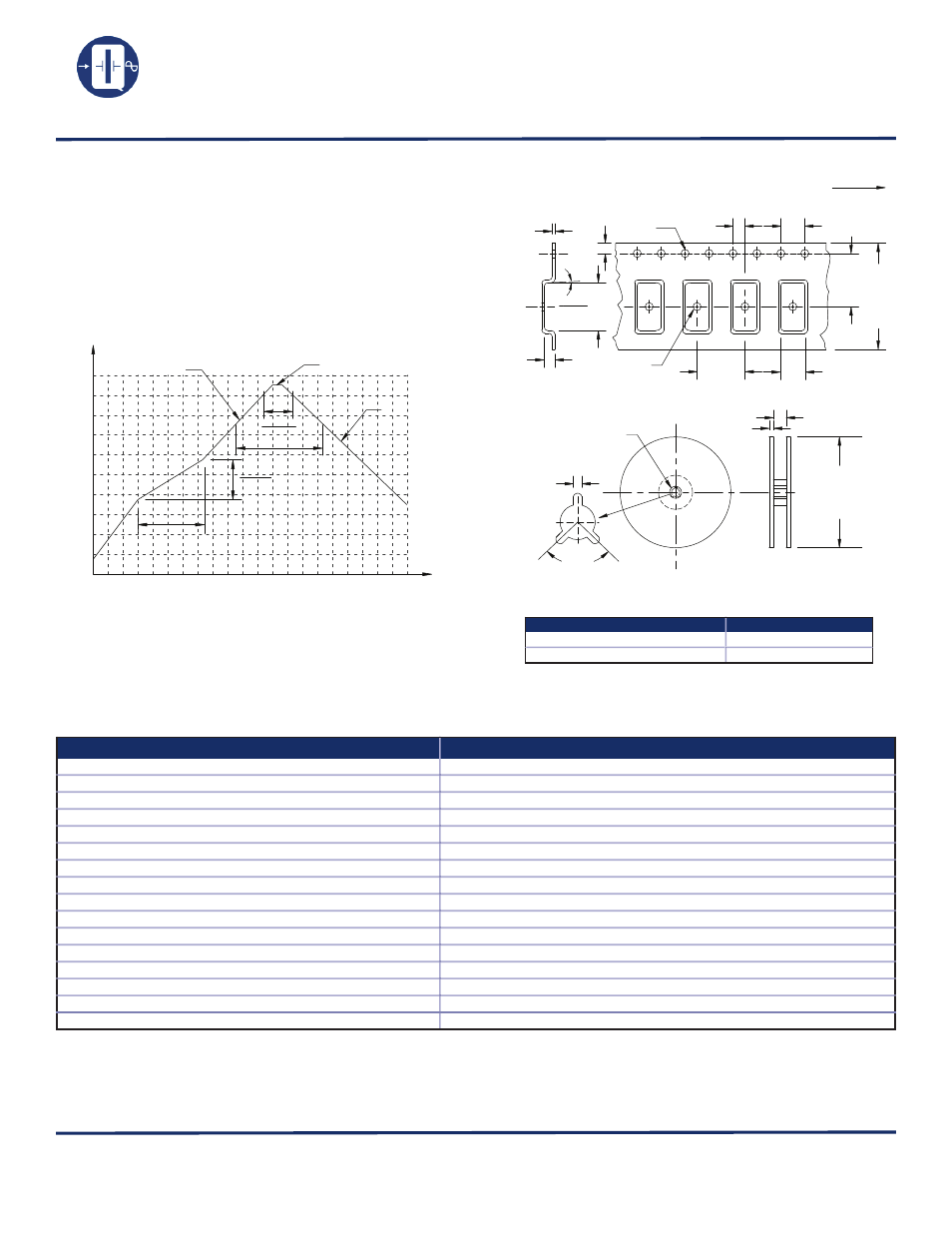

Reflow Profile

Embossed Tape and Reel Information For QT90

Environmental Specifications

The five transition periods for the typical reflow process are:

• Preheat

• Flux activation

• Thermal equalization

• Reflow

• Cool down

0

20

40

60

80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420

Time (s)

25

50

75

100

125

150

175

200

225

250

TEMP(*C)

0

60s min.

120s max.

60s min.

120s max.

225º min.

240º max.

60s min.

150s max.

240º

Ramp down (6ºC/s Max)

Ramp up (3ºC/s Max)

TYPICAL REFLOW PROFILE FOR Sn-Pb ASSEMBLY

Dimensions are in mm. Tape is compliant to EIA-481-A.

Reel size vs. quantity:

FEEDING (PULL) DIRECTION

ø13.0±0.5

2.5

6.160±0.1

5º MAX

ш1.5

2.0

1.75±0.1

0.3±.005

ш1.5

2.0±0.1

5.5±0.1

9.470±0.1

4.0±0.1

ш178±1

or

ø330±1

26

24.0±0.3

16±0.1

11.92

±0.1

120º

Reel size (Diameter in mm)

Qty per reel (pcs)

178

150

330

800

Q-Tech Standard Screening/QCI (MIL-PRF55310) is available for all of our QT90 Products. Q-Tech can also customize screening

and test procedures to meet your specific requirements. The QT90 product is designed and processed to exceed the following test

conditions:

Environmental Test

Test Conditions

Temperature cycling

MIL-STD-883, Method 1010, Cond. B

Constant acceleration

MIL-STD-883, Method 2001, Cond. A, Y1

Seal: Fine and Gross Leak

MIL-STD-883, Method 1014, Cond. A and C

Burn-in

160 hours, 125°C with load

Aging

30 days, 70°C, ±1.5ppm max

Vibration sinusoidal

MIL-STD-202, Method 204, Cond. D

Shock, non operating

MIL-STD-202, Method 213, Cond. I (See Note 1)

Thermal shock, non operating

MIL-STD-202, Method 107, Cond. B

Ambient pressure, non operating

MIL-STD-202, 105, Cond. C, 5 minutes dwell time minimum

Resistance to solder heat

MIL-STD-202, Method 210, Cond. C

Moisture resistance

MIL-STD-202, Method 106

Terminal strength

MIL-STD-202, Method 211, Cond. C

Resistance to solvents

MIL-STD-202, Method 215

Solderability

MIL-STD-202, Method 208

ESD Classification

MIL-STD-883, Method 3015, Class 1 HBM 0 to 1,999V

Moisture Sensitivity Level

J-STD-020, MSL=1

Note 1: Additional shock results successfully passed on standard QT88 family 16MHz, 20MHz, 24MHz, 40MHz, and 80MHz

• Shock 850g peak, half-sine, 1 ms duration (MIL-STD-202, Method 213, Cond. D modified)

• Shock 1,500g peak, half-sine, 0.5ms duration (MIL-STD-883, Method 2002, Cond. B)

• Shock 36,000g peak, half-sine, 0.12 ms duration

Please contact Q-Tech for higher shock requirements