Q-Tech QTV706 Sine Wave User Manual

Page 4

QTV704, QTV705 and QTV706

DDIP Sine-Wave

REV.

Q-TECH Corporation

10150 W. Jefferson Blvd.

Culver City, CA 90232

SIZE

A

CAGE NO.

51774

Sheet 4 of 7

1.0

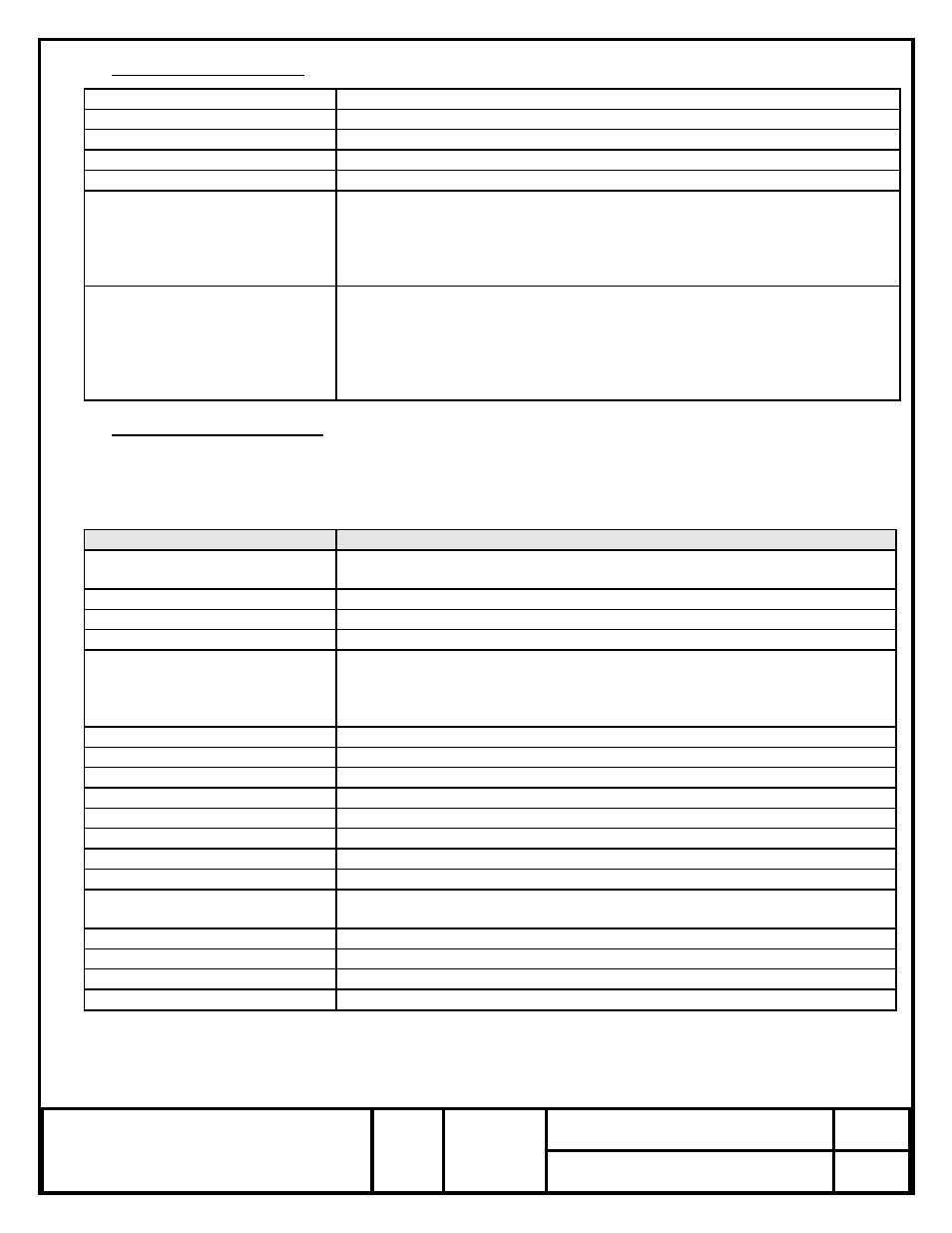

3.2.2 Environmental Conditions

Sine Vibration

MIL-STD-202, Method 204, TC “D”

Random Vibration

MIL-STD-202, Method 214 TC “I-K” (15 minutes per axis)

Shock

MIL-STD-202, Method 213, TC “F”

Acceleration

MIL-STD-883, Method 2001, TC “A”

Altitude

50,000 feet minimum to deep space

Radiation

Radiation testing is not performed, but these VCXOs have been acceptable for

use in environments up to 100K rads by analysis of the components used. Only

bipolar semiconductors are employed. A copy of the parts list and materials

can be provided for review.

The electronics used in the VCXO shall be single event latchup free.

Electrostatic Discharge Sensitivity The VCXO supplied to this drawing shall be considered to be electrostatic

discharge sensitive and require further protection and shall use one of the

packaging requirements in accordance with MIL-PRF-38534, Category A,

Section 5.3.2.4 Transportability.

The VCXO shall be capable of being transported by air, ship or road when

packaged in a suitable container.

3.3

Design and Construction

The design and construction of the crystal oscillator shall be as specified herein. As a minimum, the

oscillators shall meet the design and construction requirements of MIL-PRF-55310, except element

evaluation shall be as specified in 3.3.1.

Operation

Design, Construction &

Component Screen (see 3.3.2)

MIL-PRF-55310 Class S

Workmanship

M883, Method 2017 for Class S

Screening

MIL-PRF-55310 Class S

Non-Destruct Wire Bond Pull

100%, M883, Method 2023 (2.4 grams)

Internal Visual

MIL-STD-883, methods 2017 & 2032 condition K (class S). During the time

interval between final internal visual inspection and preparation for sealing,

hybrid crystal oscillators shall be stored in a dry, controlled environment as

defined in MIL-STD-883, method 2017 or in a vacuum bake oven.

Stabilization Bake

48 hrs minimum @ +150 C M883, Method 1008 TC B

Thermal Shock

M883, Method 1011, TC A

Temperature Cycling

M883, Method 1010, TC B

Constant Acceleration

M883, Method 2001, TC A (5000 gs, Y1 Axis only)

Seal Test (fine & gross)

100% Method 1014, (TC A1 for fine leak and TC C for gross leak)

PIND

M883, Method 2020, TC B

Electrical Test

Frequency, Output levels, Input Current@ +25 C

Burn-In (Powered with load)

+125 C for 240 hours

Electrical Test

Frequency, Output levels, Input Current

@ +25°C & Temp Extremes listed on the Electrical Specification

Radiographic

M883, Method 2012 class S

Group A

100%

Group B (30 day Aging @ +70 C) 100%

External visual

883 Method 2009