Q-tech, Qt89 series, Thermal characteristics – Q-Tech QT89 User Manual

Page 4

4

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-tech.com

QT89 SERIES

HIGH-RELIABILITY MINIATURE CLOCK OSCILLATORS

1.8 to 5.0Vdc - 15kHz to 160MHz

Q-TECH

CORPORATION

QT89 (Revision J, January 2011) (ECO #10087)

Reflow and Soldering Techniques

Environmental Specifications

Q-Tech Standard Screening/QCI (MIL-PRF55310) is available for all of our QT89 Products. Q-Tech can also customize screening

and test procedures to meet your specific requirements. The QT89 product is designed and processed to exceed the following test

conditions:

Environmental Test

Test Conditions

Temperature cycling

MIL-STD-883, Method 1010, Cond. B

Constant acceleration

MIL-STD-883, Method 2001, Cond. A, Y1

Seal: Fine and Gross Leak

MIL-STD-883, Method 1014, Cond. A and C

Burn-in

160 hours, 125°C with load

Aging

30 days, 70°C, ±1.5ppm max

Vibration sinusoidal

MIL-STD-202, Method 204, Cond. D

Shock, non operating

MIL-STD-202, Method 213, Cond. I (See Note 1)

Thermal shock, non operating

MIL-STD-202, Method 107, Cond. B

Ambient pressure, non operating

MIL-STD-202, 105, Cond. C, 5 minutes dwell time minimum

Resistance to solder heat

MIL-STD-202, Method 210, Cond. C

Moisture resistance

MIL-STD-202, Method 106

Terminal strength

MIL-STD-202, Method 211, Cond. C

Resistance to solvents

MIL-STD-202, Method 215

Solderability

MIL-STD-202, Method 208

ESD Classification

MIL-STD-883, Method 3015, Class 1 HBM 0 to 1,999V

Moisture Sensitivity Level

J-STD-020, MSL=1

Unless otherwise specified, soldering should be performed on terminals at 260ºC for 10s maximum. Do not apply soldering heat on

oscillator package since it could damage the unit. Hand soldering is recommended. Wave solder at 245ºC for 15s max.

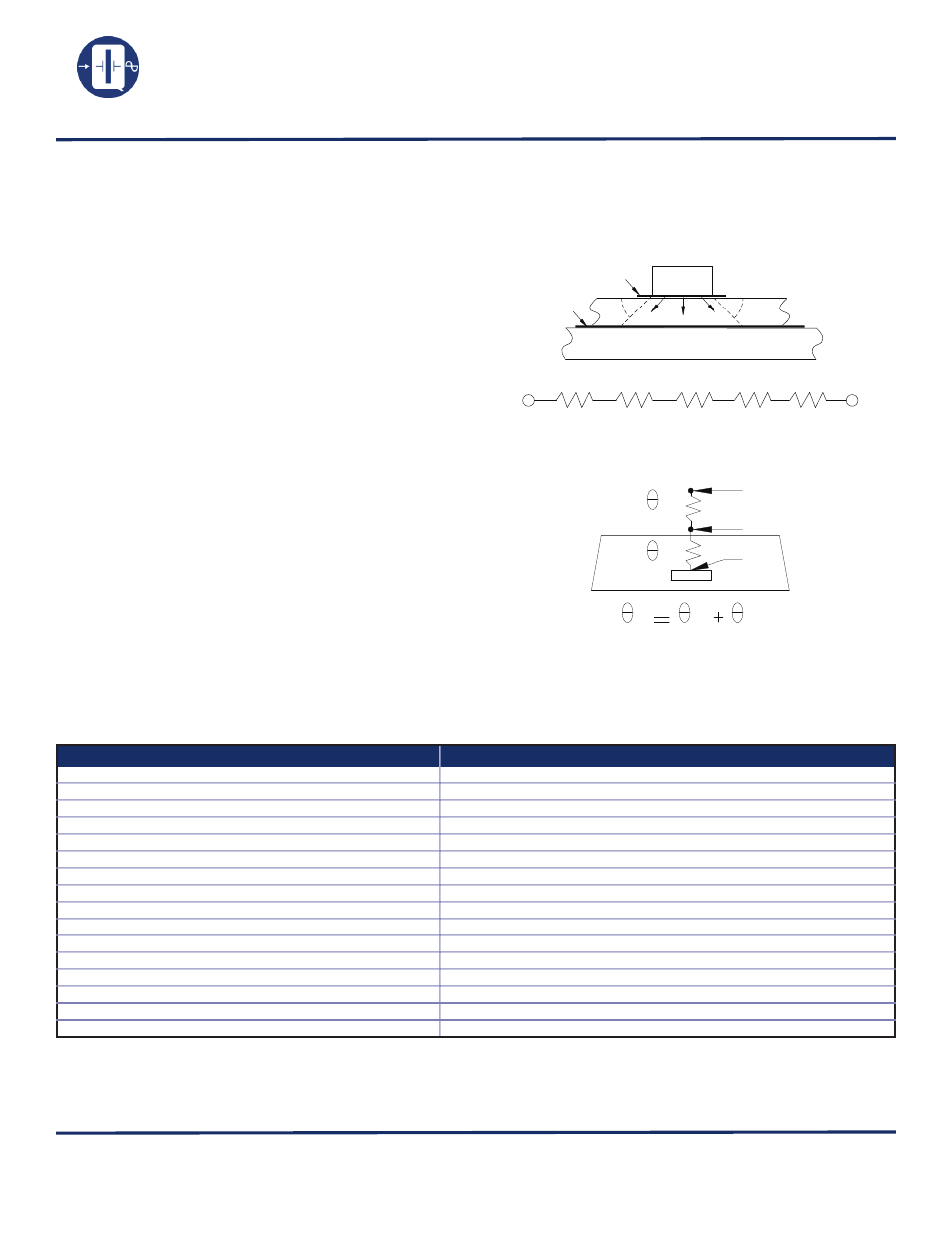

The heat transfer model in a hybrid package is described in

figure 1.

Heat spreading occurs when heat flows into a material layer of

increased cross-sectional area. It is adequate to assume that

spreading occurs at a 45° angle.

The total thermal resistance is calculated by summing the

thermal resistances of each material in the thermal path be-

tween the device and hybrid case.

RT = R1 + R2 + R3 + R4 + R5

The total thermal resistance RT (see figure 2) between the heat

source (die) to the hybrid case is the Theta Junction to Case

(Theta JC) in°C/W.

• Theta junction to case (Theta JC) for this product is 30°C/W.

• Theta case to ambient (Theta CA) for this part is 100°C/W.

• Theta Junction to ambient (Theta JA) is 130°C/W.

Maximum power dissipation PD for this package at 25°C is:

• PD(max) = (TJ (max) – TA)/Theta JA

• With TJ = 175°C (Maximum junction temperature of die)

• PD(max) = (175 – 25)/130 = 1.15W

45º

45º

Hybrid Case

Substrate

Die

D/A epoxy

D/A epoxy

Heat

Die

R1

D/A epoxy

Substrate

D/A epoxy

Hybrid Case

R2

R3

R4

R5

JA

JC

CA

Die

T

T

T

C

A

J

CA

JC

(Figure 1)

(Figure 2)

Thermal Characteristics

Note 1: Additional shock results successfully passed on standard QT88 family 16MHz, 20MHz, 24MHz, 40MHz, and 80MHz

• Shock 850g peak, half-sine, 1 ms duration (MIL-STD-202, Method 213, Cond. D modified)

• Shock 1,500g peak, half-sine, 0.5ms duration (MIL-STD-883, Method 2002, Cond. B)

• Shock 36,000g peak, half-sine, 0.12 ms duration

Please contact Q-Tech for higher shock requirements