Q-tech, Leadless chip carrier, 5 of 7 – Q-Tech QT75 User Manual

Page 5: Thermal characteristics, Environmental specifications

5 of 7

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-tech.com

LEADLESS CHIP CARRIER

CRYSTAL CLOCK OSCILLATORS

1.8 to 15Vdc - 732.4Hz to 150MHz

Q-TECH

CORPORATION

QPDS-0011 (Revision H, April 2013 ) (ECO# 10850)

45º

45º

Hybrid Case

Substrate

Die

D/A epoxy

D/A epoxy

Heat

Die

R1

D/A epoxy

Substrate

D/A epoxy

Hybrid Case

R2

R3

R4

R5

Thermal Characteristics

JA

JC

CA

Die

T

T

T

C

A

J

CA

JC

(Figure 1)

(Figure 2)

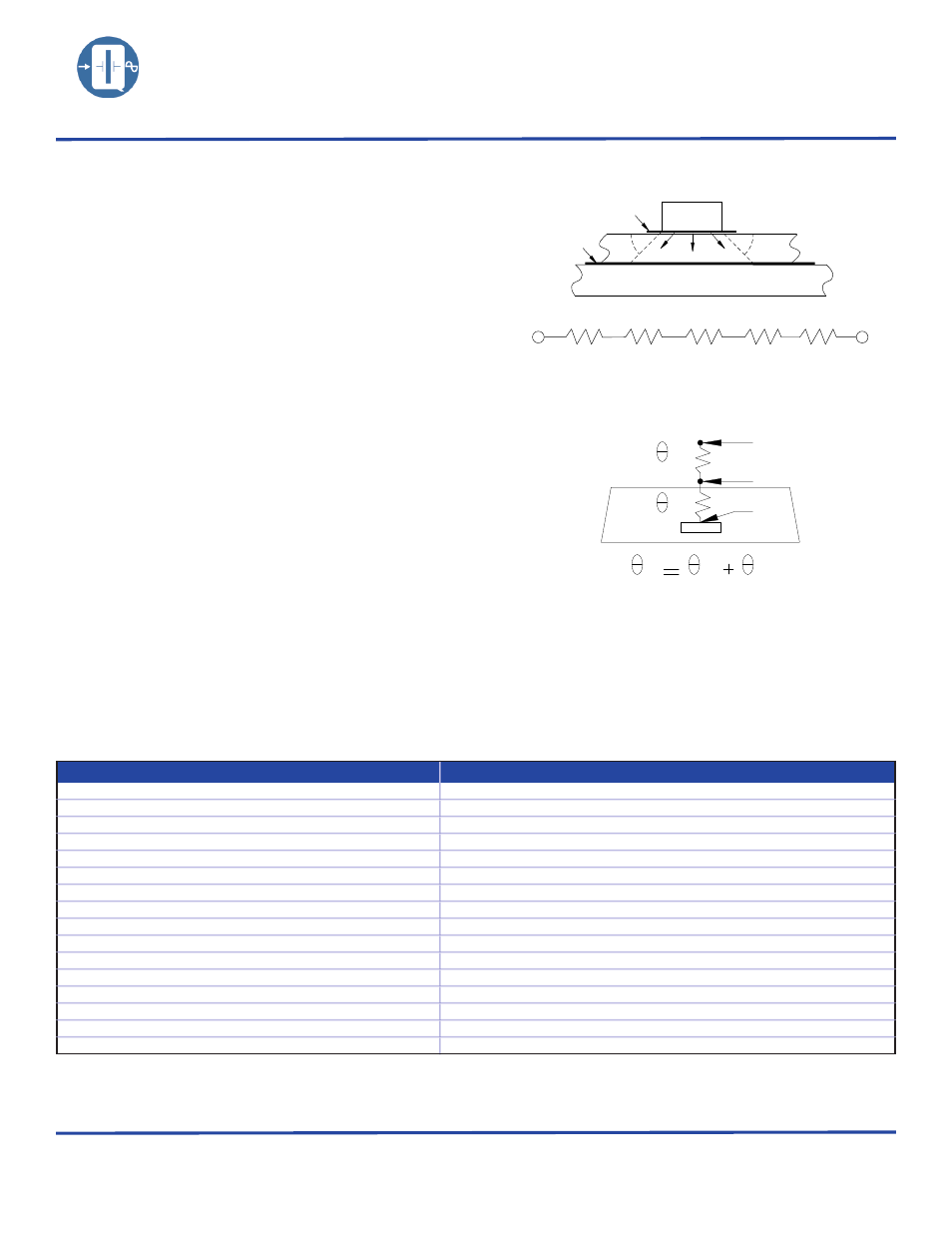

The heat transfer model in a hybrid package is described in figure 1.

Heat spreading occurs when heat flows into a material layer of

increased cross-sectional area. It is adequate to assume that spreading

occurs at a 45° angle.

The total thermal resistance is calculated by summing the thermal

resistances of each material in the thermal path between the device

and hybrid case.

RT = R1 + R2 + R3 + R4 + R5

The total thermal resistance RT (see figure 2) between the heat source

(die) to the hybrid case is the Theta Junction to Case (Theta JC)

in°C/W.

• Theta junction to case (Theta JC) for this product is 30°C/W.

• Theta case to ambient (Theta CA) for this part is 100°C/W.

• Theta Junction to ambient (Theta JA) is 130°C/W.

Maximum power dissipation PD for this package at 25°C is:

• PD(max) = (TJ (max) – TA)/Theta JA

• With TJ = 175°C (Maximum junction temperature of die)

• PD(max) = (175 – 25)/130 = 1.15W

Environmental Specifications

Q-Tech Standard Screening/QCI (MIL-PRF55310) is available for all of our Leadless Chip Carrier packages. Q-Tech can also

customize screening and test procedures to meet your specific requirements. The Leadless Chip Carrier packages are designed and

processed to exceed the following test conditions:

Environmental Test

Test Conditions

Temperature cycling

MIL-STD-883, Method 1010, Cond. B

Constant acceleration

MIL-STD-883, Method 2001, Cond. A, Y1

Seal: Fine and Gross Leak

MIL-STD-883, Method 1014, Cond. A and C

Burn-in

160 hours, 125°C with load

Aging

30 days, 70°C, ± 1.5ppm max

Vibration sinusoidal

MIL-STD-202, Method 204, Cond. D

Shock, non operating

MIL-STD-202, Method 213, Cond. I

Thermal shock, non operating

MIL-STD-202, Method 107, Cond. B

Ambient pressure, non operating

MIL-STD-202, 105, Cond. C, 5 minutes dwell time minimum

Resistance to solder heat

MIL-STD-202, Method 210, Cond. B

Moisture resistance

MIL-STD-202, Method 106

Terminal strength

MIL-STD-202, Method 211, Cond. C

Resistance to solvents

MIL-STD-202, Method 215

Solderability

MIL-STD-202, Method 208

ESD Classification

MIL-STD-883, Method 3015, Class 1HBM 0 to 1,999V

Moisture Sensitivity Level

J-STD-020, MSL=1

Please contact Q-Tech for higher shock requirements